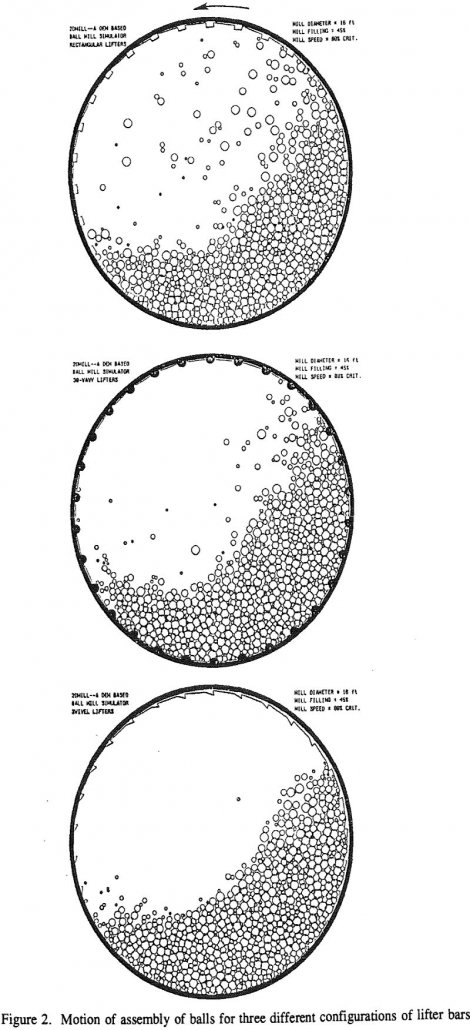

How Ball Mills Lifter Bar Affects Charge Motion

In ball mills, the grinding of ore bodies takes place due to the impact and attrition of the colliding balls. For efficient grinding of hard materials, high-impact velocities are required. For a given rotating speed and filling of the mill, impact velocities of balls and the nature of forces developed inside the mill can be […]

Pebble Crushing in SAG Mill Circuit

Full Scale Test Circuit Based upon the results of the pilot plant test work, a decision was made to conduct a full scale test in 1990 utilizing one of the ten (10) primary mill lines at the National Steel Pellet Plant. Primary Mill Line No. 10 would be converted to a fully autogenous grinding mill […]

Hydrostatic Trunnion Bearing Design

Hydrostatic trunnion bearings were recently provided on large Semi-Autogenous Grinding (SAG) mills driven by wraparound motors assembled on the head to shell flanges. A conventional SAG mill would have a ring gear driven through one or two pinions. The effects of the magnetic air gap forces from this new SAG mill drive arrangement on the […]

Pebble Crushing

The Bagdad mill, built in 1977, was designed for a mill capacity of 36,300 tpd. An ABC (Autogenous Mill-Ball Mill-Crusher) grinding circuit was chosen. The original mill contained three completely independent grinding circuits, each containing one 9.75 m diameter by 3.96 m long fixed speed autogenous mill, one 4.72 m diameter by 6.71 m long […]

Wet Semi-Autogenous Grinding Mills

The primary mill liner task force was formed in 1977. Its function was to improve the operating costs and milling efficiencies of the ten 8.2-m x 5.5-m (27 ft x 18 ft) wet SAG mills that were operating at the time. The SAG mills are driven by two 3500 HP motors drawing a total of […]

SAG Mill Variable Speed Drive

Large scale equipment can reduce both capital and operating costs for concentrators. Large semiautogenous mills can be effectively utilized in big mills but they must be kept fully loaded to take advantage of their great potential. With varying hardness ores, controlling throughput is difficult and careful design must take this into consideration. A variable speed […]

Thin Layer Wet Screening

Size reduction of ore in the refining process is necessary to liberate or expose the desired component of the raw ore. The geology of the ore deposit and the nature of the ore determine the extent to which the ore must be reduced to maximize the recovery economically. Size reduction of the raw ore is […]

Semi-Autogenous Grinding Cost Benefits

There has been a great deal of evaluation and discussion on the economics of semi-autogenous grinding versus conventional grinding circuits. The Henderson Mill, owned and operated by AMAX, Inc., is located 20 miles southeast of Parshall, Colorado. There are minor amounts of galena, chalocopyrite, sphalerite and about 3% pyrite. The major rock type is potassium […]

Zero Order Production of Fines in Grinding

The phenomenon of zero order production of fines associated with the batch comminution of monosize feeds in tumbling mills has been examined in the context of the size discretized population balance model. It has been shown that the model admits zero order production kinetics only in an approximate sense. The necessary and sufficient conditions for […]

Things to do to Improve Metallurgical Performance

Alternative methods to restrict and eliminate the detrimental effect of critical size material on the performance of an autogenous mill. Palabora has a unique orebody in that it contains most of the valuable minerals known, but unfortunately also some gangue minerals which have a major influence on the milling rate. The two gangue minerals having […]