CIL & CIP Leach Circuit Simulation

Stamp Mill Animation

When stamp mills are used for dry crushing, double discharge mortars are provided (see Fig. 50), and the screens are put low down, giving a small depth of discharge. These arrangements are necessitated by the difficulty of discharging the crushed ore from the mortar, the only means of doing this being the dashing of the […]

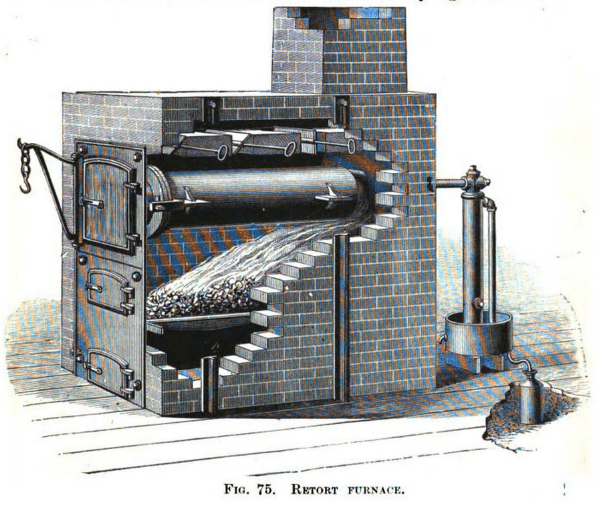

Retort Furnace, Retorting Pot & Condensing Pipe

This retort furnace, is an improvement on those formerly constructed. It has three dampers for directing the flames and heat from back to the front end of the retort. As the entire retort and its cover is within the furnace the mercury is equally driven off from all parts of the amalgam, leaving the whole mass […]

Estimation of Free Cyanide using Iodine and Potassium

The process of estimating free cyanide depends upon the fact that when a solution of iodine in potassium iodide is added to a solution of a simple cyanide, the reddish-brown color of the iodine solution disappears so long as the cyanide is in excess, since the reaction results in the formation of an iodide of […]

Cyanide Leaching of Flotation Concentrate

When Charles Butters began to take up the work of flotation in our Oakland laboratory, one of the first points brought to our attention was the treatment of the concentrate produced by flotation; J. E. Clennell was accordingly instructed to undertake the researches detailed in the present paper. The whole value of the process hinges […]

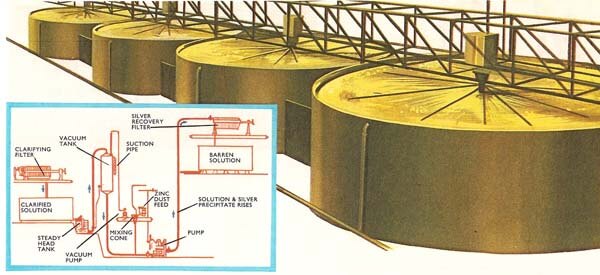

Merrill-Crowe Zinc Precipitation Circuit Operation

In the Merrill-Crowe Zinc Precipitation, the pregnant solution tank collects the gold and silver bearing solution recovered from other circuits of the plant: thickener overflow; primary and secondary filtration? and the Argentite circuits. Normally these solutions contain very little solids content (15-100 ppm), however, even this small amount of solids is sufficient to inhibit efficient […]

Silver Sulphide Leaching & Filtration Circuit Startup & Shutdown Procedures

Details of good silver sulphide leaching and filtration circuit operation and instructions for sequencing and preparing for startup. The following items must be checked before the equipment in this EXAMPLE Argentite Leaching Circuit is started. The leach tank agitators should be running. Check that the Argentite filter feed pump, drum filter, repulper and tailings sampling pump […]

Silver Flotation Concentrate Leaching and Filtration Circuits

Producing a Silver Flotation concentrate from this EXAMPLE Argentite (cubic silver sulfide (Ag2S)) Flotation Circuit enters the first of four successive Argentite leach tanks. The purpose of this leach circuit is to dissolve the silver and gold recovered in the Flotation Circuit. A high strength solution of sodium cyanide, air, and lime are added to the […]

Startup and Shutdown Procedure -Merrill Crowe

In Preparation for Startup, the following items must be checked before the equipment in the filtration circuit is started. Check that the filters, repulpers, filtrate pumps, vacuum pumps, flotation blower, and transfer pumps are ready to run. Check that the cooling water compressant system is functional. The selected cooling water filter must be clean, and reclaim water must […]

Merrill Crowe Slurry Filtration Circuit Post-Agitated Leach

The object of the post agitated leach drum filtration circuit is to recover as much of the dissolved gold and silver as possible. The efficiency of recovery can be increased significantly by utilizing two successive stages of filtration such as the two stage system applied in this plant. Recovery of the precious metals is also improved […]