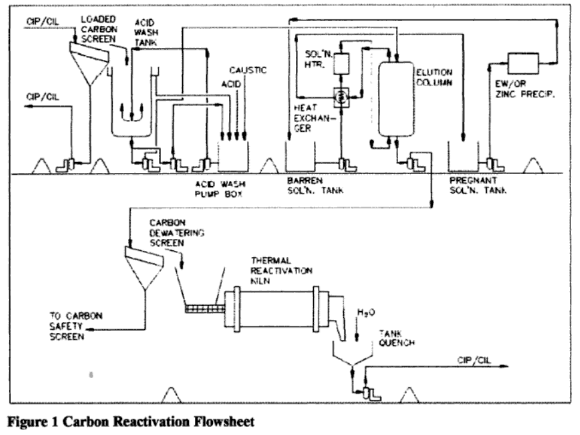

Washing Activated Carbon

In the process of washing activated carbon, a dilute hydrochloric acid solution (3%) is circulated/pumped into the elution column. The acid dissolves inorganic foulants such as calcium carbonate, magnesium and sodium salts, fine ore Minerals such as silica, and fine iron particles. The carbon acid wash cycle takes about 4.30 hours. Acid washing may also help […]

Electrolytic Gold Extraction

Gold is so widely distributed in nature and is so much desired on account of its value that the metallurgy of gold is not only one of the most fascinating but also one of the most important industries. Gold occurs in several forms in nature: as free gold; in combination with sulphur, or in the metallic state […]

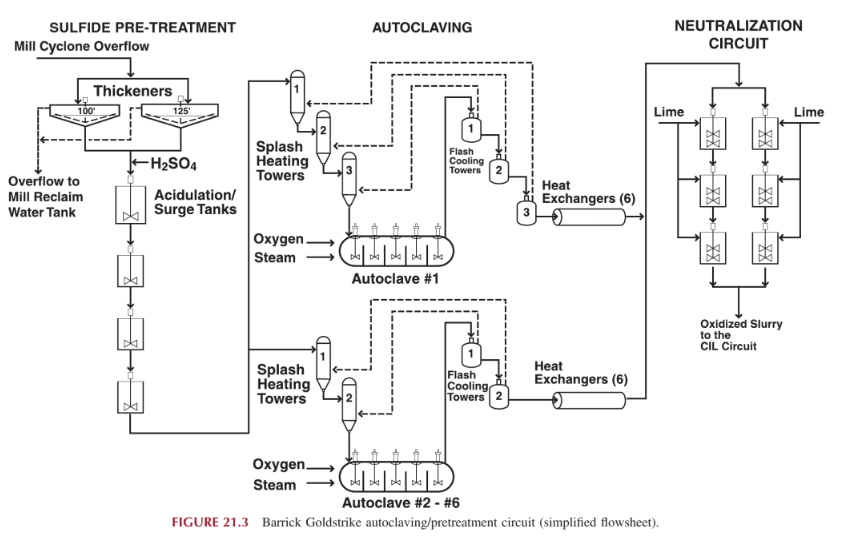

Autoclave Circuit & Gold

Slurry from the grinding circuit, at approximately 35% solids and 80—85% passing 135 mm is pumped to three thickeners. Thickener underflow, at approximately 54% w/w solids, is pumped to a train of four acidulation tanks. Sulfuric acid is added to the slurry to destroy sufficient carbonate prior to entering the autoclave circuit. Process air is […]

Sodium Thiosulphate Gold Leaching

The gold industry has been seeking alternative reagents for leaching gold from low-grade ores for the past 25 years. The cost and transport of cyanide, the poor recovery of gold from carbonaceous ores, the lack of selectivity of cyanide towards copper minerals and the cost of waste treatment are real factors which can make cyanide […]

Edwards mechanical ore-roasting furnace

The (Edwards Type) Mechanical Roaster was first developed in Australia for the roasting of gold and silver ores and concentrates. It can be built in units to handle from 20 to 200 tons per 24 hours. The overall height of this type of unit is low, an important advantage in installation. Dusting is eliminated because the […]

Cyanide Pre-Leach Conditioner

The notably successful application of flotation to many cyanide ores, and the development of a plant to treat the flotation concentrates by cyanidation, makes it possible for small plants to increase their recovery greatly and to make a much wider margin of profit. These concentrate treatment plants do not require large outlays of money and […]

Portable Gold Processing Plant

Portable Gold Amalgamation Plant Free milling gold and silver ores are efficiently and economically treated in Amalgamation Mills. These mills are often used in the early stages of development of free milling gold properties to recover the main portion of the gold with a simple, inexpensive flowsheet. Later a more comprehensive installation can recover the […]

Laboratory Cyanide Leach Plants

The (Batch) Laboratory Cyanide Plant was designed to assist the purchaser in determining what style of plant he needs for his particular ore. While an assayer’s test offers no particular difficulty, the ore may pack and prove impervious to solution when full size mill operation is attempted. To do away with this possibility a low […]

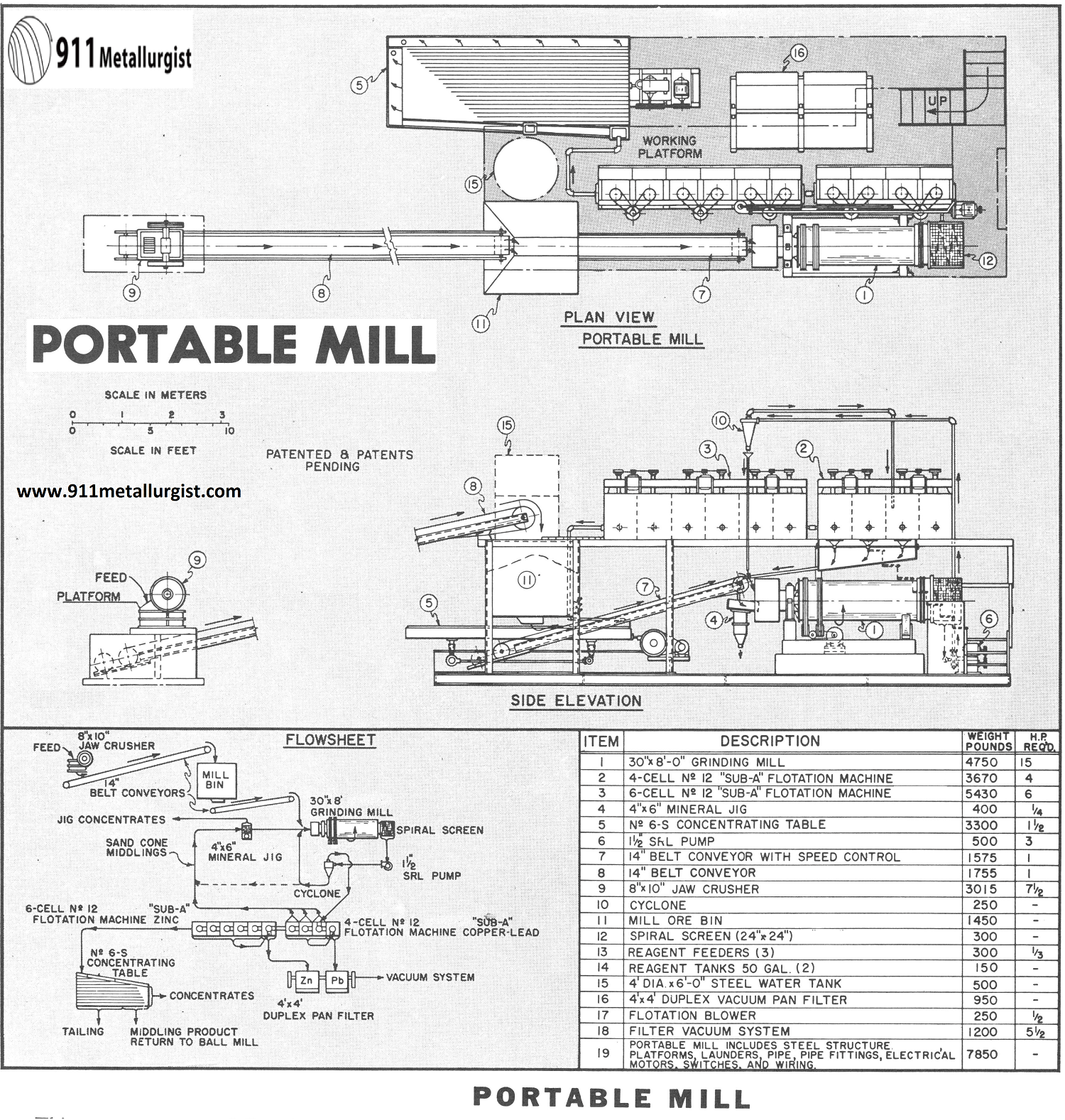

Small Portable Gold Process Plant

This arrangement and flowsheet of a Mini Portable Gold Processing Plant permits several mineral separations by flotation and provides for the possible recovery of other minerals by gravity concentration. The flowsheet is ideal for a pilot-plant in field testing of ores to determine the economic feasibility of an ore deposit prior to the installation of […]

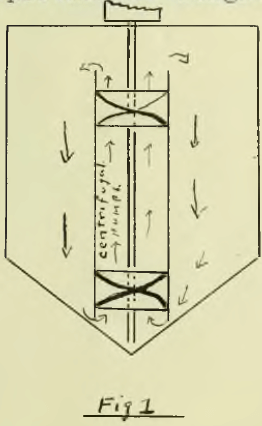

Leaching Plant Design

Leaching plants, faced with increased tonnage, coarse (up to —3/16″ solids) feed, longer retention time, erosion, corrosion and the high cost of space, must be compact, simple and highly efficient. The engineer faced with the obvious economy of using a few large agitators compared to many smaller units must also evaluate the design factors which will prevent the settling-out of solids, provide […]