Determine the Proper Grind Size for Gold Ore

Without mineralogy, estimating the optimum Grind Size for Gold Ore Sample is most conveniently made by Laboratory Testing and the agitation leaching method, and it will be necessary to make up 3 or 4 bottle charges in order to have enough ore* for the subsequent screen analysis. Take an average sample of the ore and grind […]

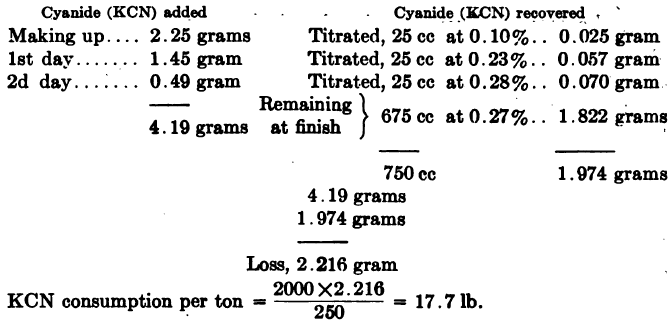

Calculating Cyanide Consumption

Computing Cyanide Consumption of a laboratory leach test may be done as in the following example: Ore taken, 250 grams. Ratio of solution to ore, 3:1 = 750 cc: 250 grams. Cyanide strength, 0.3% KCN. Or when working on the metric system, Ore taken 200 grams, ratio of solution to ore 3:1 = 600 cc: 200 grams, […]

How to Test Ore or Rock for Gold Content

In all experiments aimed at testing the gold content of rocks or “ore”, you should ask yourself whether the conditions of his test differ in any vital particular from those that would obtain on a commercial scale; if so, there is no guarantee that his results would be borne out in a working plant. Small scale […]

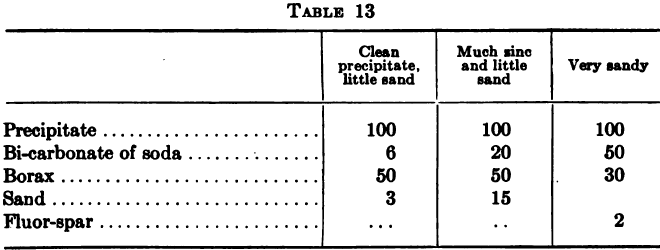

Cleaning & Melting Gold Precipitate

With zinc shaving precipitation the usual method of cleanup is to shut off the flow of solution and starting at the head compartment of a box to wash the shavings gently in the solution avoiding any action that would tend to break up the attenuated threads into short pieces. The zinc is then removed and […]

Tavener Process – Smelting Gold with Lead & Flux

The Tavener process of melting the gold precipitate in a reverberatory furnace with litharge, thus forming a lead bullion which was afterward cupelled in the usual way. He deals with the zinc shorts by the same method but recommends that the two products be partially dried and separately fluxed. For the precipitate he uses the […]

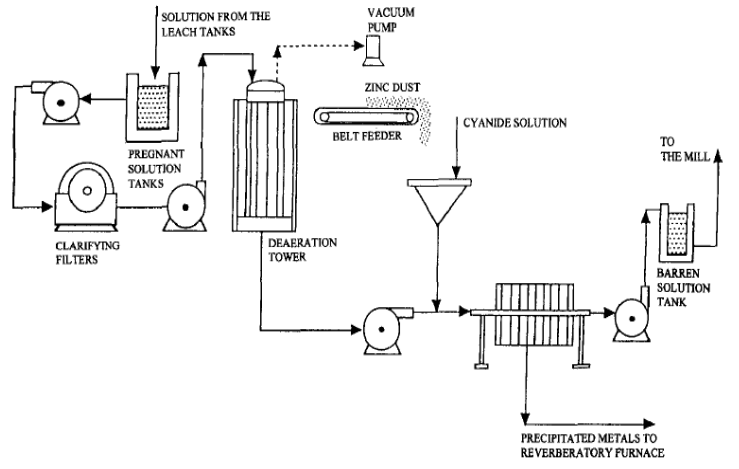

Gold Precipitation

Whatever method of gold precipitation be used it is of great importance that the solution should be absolutely clear and free from suspended matter, and in practice it is almost impossible to obtain solution from slime treatment, either by decantation or by means of the various types of slime filter, that is sufficiently clean to […]

Precipitation of Gold on Carbon – Charcoal

Park states that this method is in use in many plants in Victoria for precipitating gold from cyanide solutions the procedure being to pass the solution through barrels packed with finely broken carbon/charcoal, which is afterward burned, and the ash melted down with fluxes. He does not consider it suitable for large tonnages of solution. […]

Gold Recovery by Aluminium Precipitation

The use of aluminium as a precipitant for gold out of cyanide solutions was patented by Moldenhauer but he does not appear to have made any practical use of the process. H. F. Julian experimented with it, in the same year, but soon abandoned the idea. Kirkpatrick introduced it at the Deloro Smelter in Canada, […]

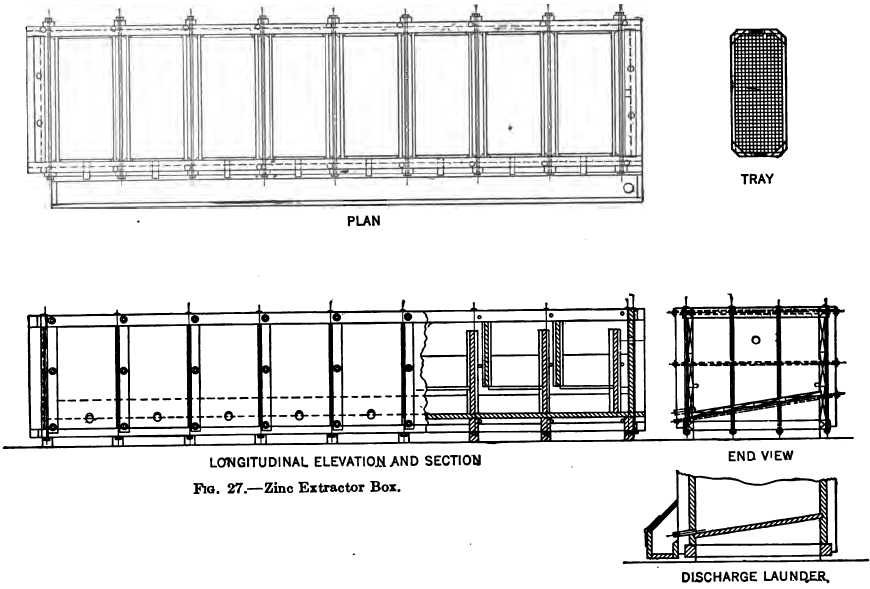

Recovery of Gold by Precipitation with Zinc

The recovery of the precious metals like gold and silver from the cyanide solution is almost universally accomplished by precipitation with zinc, either in the form of fine threads or of dust (the condensed fume recovered in the process of retorting the metal). The phenomena of precipitation are essentially electrical and may be traced to […]

Electrolytic Precipitation of Gold

This was introduced on a commercial scale as an adjunct to the cyanide process on the Rand for precipitating the weak and low-grade solutions resulting from the treatment of slime by decantation, and was known as the Siemens Halske process. The anodes were of sheet iron enclosed in burlap to prevent short circuiting and the […]