Treatment of Cyanide Precipitate AKA Gold Pregnant Solutions

Comparatively little trouble was experienced in gold milling with regard to the preparation of a pure bullion until the advent of the cyanide process. When ores were smelted the litharge method of elimination of baser metals and the subsequent parting had been worked out in fine detail. When alluvial gold was collected and smelted the […]

Electrolytic Refining of Gold

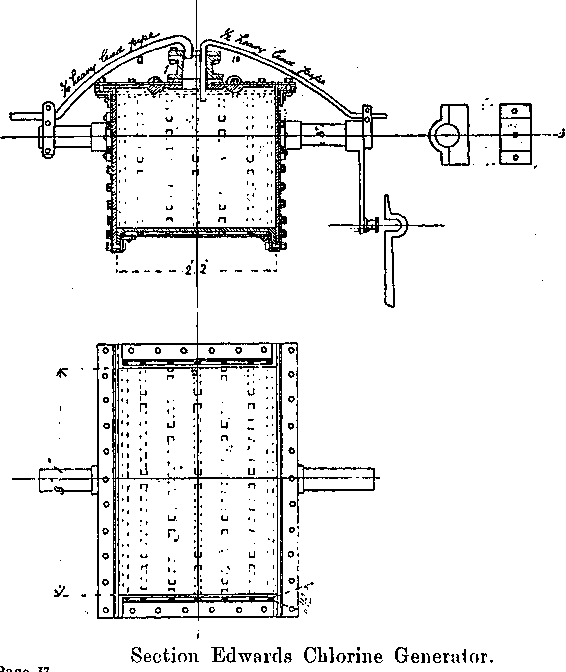

The method just described aims at leaving gold in an insoluble state at the anode. Other impurities are usually left there, and the gold sponge, or slimes, needs further refining by methods, to be indicated later. By using a suitable electrolyte the gold can be dissolved from the anode bars and deposited in sheet form […]

Separating Gold from Silver by Electrolysis

This attractive method of separating gold from silver has made some headway, and will in many cases replace other methods of parting. The electrolyte used is a solution of silver nitrate, or it may be started with dilute nitric acid. The cathode consisting of thin silver plate and the anode of the silver-gold alloy usually in […]

Refining Gold with Sulphuric Acid

Pure silver is readily attacked by strong hot sulphuric acid of SG 1.815, or about 90 per cent, strength. The reaction which takes place may be represented as follows: 2Ag + 2H2 SO4 = Ag2 SO4 + 2H2O + SO2 Silver sulphate so produced is very soluble in the strong acid, when it is hot, as […]

How to Recover Silver from Nitrate Solutions

The usual method of recovering silver from these solutions is to precipitate the silver by means of common salt. From an ordinary alloy the only salts likely to be precipitated are mercurous chloride and lead chloride. The former would be present in traces only, and would be eliminated in subsequent operations. Lead is generally removed […]

Commercial Scale Gold Parting with Nitric Acid

The method of gold parting with nitric acid usually consists in: Granulating the alloy, which should he free from antimony, tin, or sulphides. Treating with dilute nitric acid, and decanting the solution. Boiling with strong nitric acid. Washing the parted gold free from alloy. Smelting the parted gold. Recovering the silver from solution. The granulating […]

Gold Parting using Nitric Acid

The process of parting gold with nitric acid is old, and probably dates from the discovery of nitric acid itself; it is one of the simplest parting processes, and does not require a costly plant or much manipulative skill. The main objection to it is the cost of the acid. The operation comprises the preparation […]

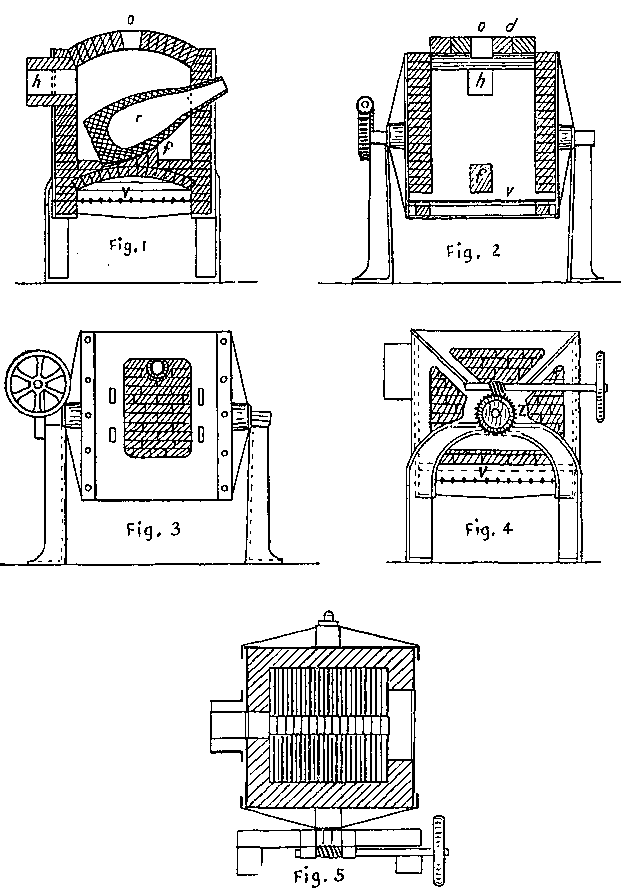

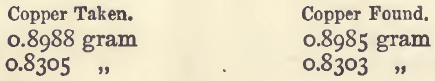

Miller Gold Refining Process by Chlorination

The term refining has been very often applied to the removal of base metals from the noble ones, or, in other words, separating the oxidizable from the non-oxidizable ones. When used in this sense it is generally applied to the term bullion, which is an alloy carrying gold and silver, the bullion being pure when […]

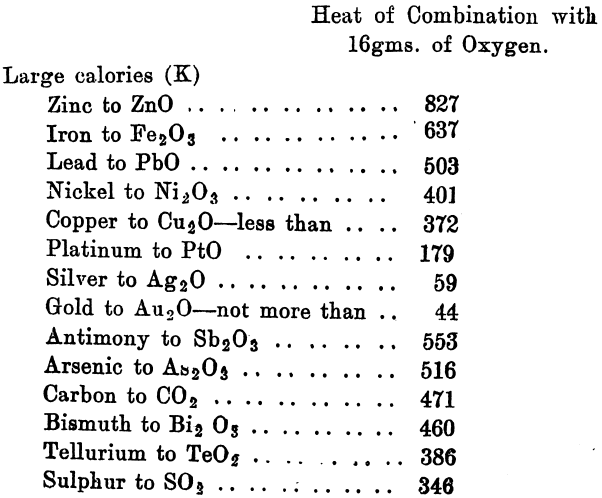

How to Refine Gold Bullion with Oxygen or Air

The how-to method of removing oxidisable metals by means of an oxidising agent has been practised for centuries. The operation has already been described in the cementation process with nitre, and the gaseous method of removing antimony from gold. The ordinary cupellation operations are also on the same lines. When oxidising fluxes are used, their action […]

How to Separate Silver & Gold by Cementation

Older processes explaining how to go about separating silver from gold by cementation were carried on practically in two ways, the first by heating gold for a long time with a mixture which evolved nitric acid on heating, and an absorbent into which any fusible salts ran; the mixture in the second method contained common salt […]