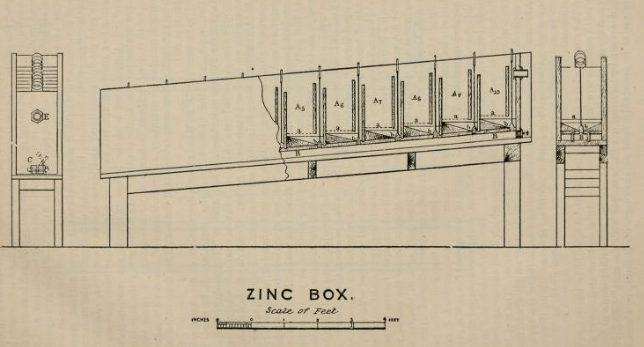

Zinc Box for Gold Bullion Precipitation

It was generally believed at one time that the precipitation of gold and silver by zinc was effected by simple displacement, according to the equation: 2KAuCy2 + Zn = K2ZnCy4 + 2Au Some considerations have been adduced, however, which throw doubt on this view. It is well known that a considerable excess of free cyanide must […]

How to Make Gold Bullion

Various gold bullion making methods have been suggested for effecting the elimination of the zinc and other base metals. The chief ones are: Direct fusion with fluxes. Roasting, followed by fusion. Treatment with sulphuric acid, followed by fusion. Lead fusion and cupellation (Tavener process). Volatilisation of the zinc, followed by fusion. Direct Fusion The method […]

Cleaning the Gold Precipitate Bullion Box

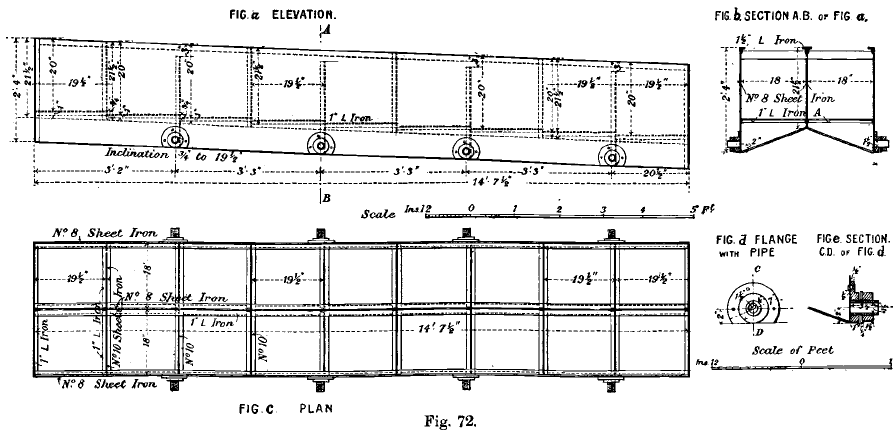

There is one precipitation house and refinery common to all the leaching buildings. The method of precipitation is by zinc shavings, which, with slight modifications, answers admirably for all strengths of solution, the strong solutions ranging from .70 per cent. KCy to .25 per cent. KCy; the weak from .25 per cent. KCy to .10 […]

Chemical Precipitation on Mercury

The Chemical Precipitation on Mercury of the Gilmour – Young Process is a method that has been employed at the Santa Francisca Mine, Nicaragua. The ore contains a very large percentage of clay, the slimes amounting to 70 per cent, of the ore. The ore is crushed by a No. 5 Krupp ball mill through a […]

Electrical Precipitation on Mercury or Amalgamated Plates

In the Siemens-Halske Electrical Precipitation process, the gold is deposited from solution by the passage through the liquid of a current of electricity. Moreover, as the precipitation is as readily obtained in extremely dilute cyanide solutions as in those containing 0.1 per cent, or more, very weak solutions are used in dissolving the gold from […]

Treatment of tellurides without roasting

Among other suggestions for rendering the presence of oxygen in cyanide solutions unnecessary, the most striking was The Sulman-Teed Process, who use cyanogen bromide, CNBr. The addition of this substance to a solution of potassium cyanide makes it much more rapid in dissolving gold. They put forward the equation: CyBr + 3KCy + 2Au = […]

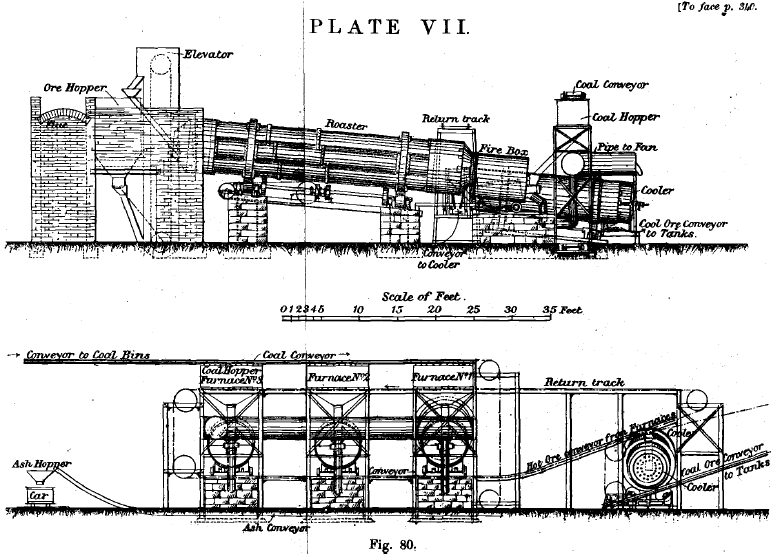

Roasting in Metallurgy

In metallurgy, the operation of roasting, as a preliminary to chlorination, has for its object the expulsion of the sulphur, arsenic, antimony and other volatile substances existing in the ore, and the oxidation of the metals left behind, so as to leave nothing (except metallic gold) which can combine with chlorine when the ore is […]

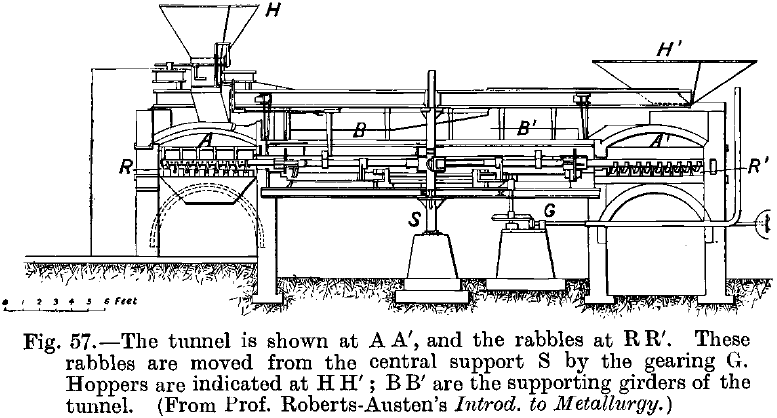

Reverberatory Furnace

The construction of the ordinary reverberatory furnace is too well known to need detailed description here. It consists of a vaulted chamber, containing the ore; through this chamber, the flames and products of combustion from a reverberatory furnace and a current of air are made to pass in a horizontal direction above the ore, which is […]

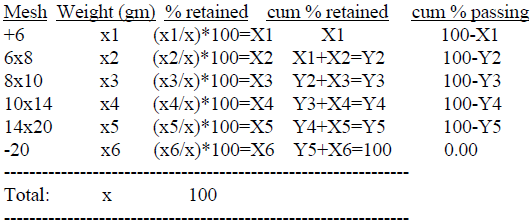

Procedure & Method for Activated Carbon Testing Program

OBJECTIVE: Evaluation of Westates Metasorb 321G (6×12) virgin activated carbon as compared to medium activity carbon from alternate vendors. PROJECT SCOPE: The following variables will be evaluated: Apparent density. Initial moisture content. Fine carbon losses following pre-soak. Particle size distribution of pre/post attrited carbon. Attritioning rates and losses with/without silica media. 24 hour adsorption rate and […]

Mechanical Roasting in Silver-Lead Smelting

What Colonel Dwight says regarding the treatment of oxidized ores holds true also of the silver-lead smelting operations in Utah. The ore sought for was such as would, with appropriate fluxes, yield slag, and “lead bullion,” as the lead reduced from the ore and carrying its gold and silver, was called. No matte, and probably […]