Miller Chlorine Process

The use of chlorine gas for the purification of molten gold was first proposed by L. Thompson, and the results of his investigations were published in the Journal of the Society of Arts two years later. He stated that “ it has long been known to chemists, that not only has gold no affinity to […]

Gutzkow Process to Refine Gold

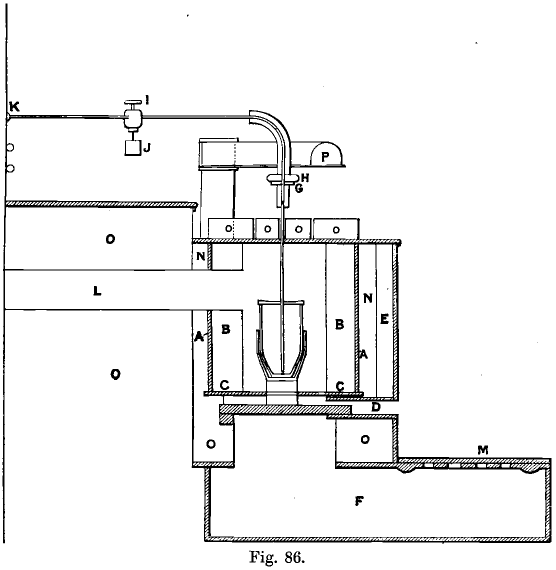

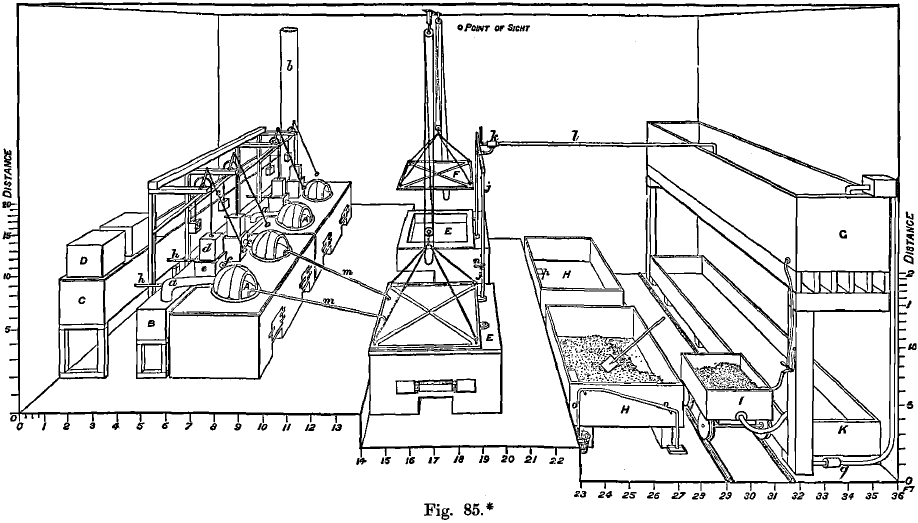

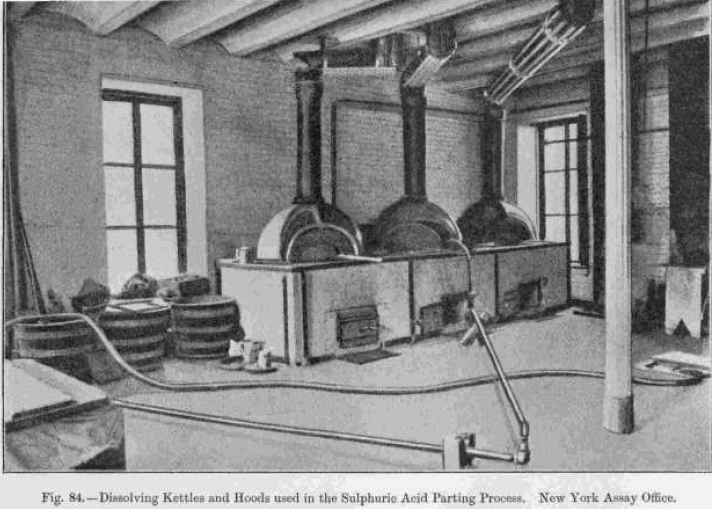

This Gutzkow Process of parting by sulphuric acid was invented and patented by Mr. F. Gutzkow. It has been extensively worked in Germany and in San Francisco, and up to the year 1891 had been instrumental, on the authority of Mr. Gutzkow, in refining one hundred million dollars’ worth of silver. It is fully described in […]

Sulphuric Acid Parting of Gold & Silver

This process has now, in the majority of refineries, superseded the nitric acid method, which is much more expensive, owing to the higher cost of the acid used and of the plant required. The German chemist, Kunckel, who lived in the seventeenth century, is said to have been the first to employ sulphuric acid in […]

Silver Chloride Reduction

The silver chloride is then reduced in lead-lined tanks by means of granulated zinc and water acidulated with sulphuric acid. Thirty-three pounds of commercial granulated zinc are stated to be enough to reduce 100 lbs. of silver from the chloride. The reactions involved are as follows: 2AgCl + Zn = ZnCl2 + 2Ag Zn + […]

Gold Alloy Granulation

The gold to be parted must be approximately free from base metals, particularly from those which are not soluble in nitric acid, such as tin, arsenic, antimony. If these were present they would form insoluble oxides, which would remain with the gold, so that further refining operations would be necessary: they would, moreover, cause a […]

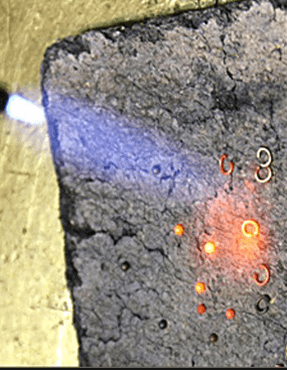

PARTING: Separate Gold and Silver by Melting

Parting is the separation of silver from gold and a process during which the base metals are separated from both, but, as the presence of a high percentage of these base metals is injurious to the successful conduct of the processes which are chiefly in use, a preliminary refining by one of the methods already […]

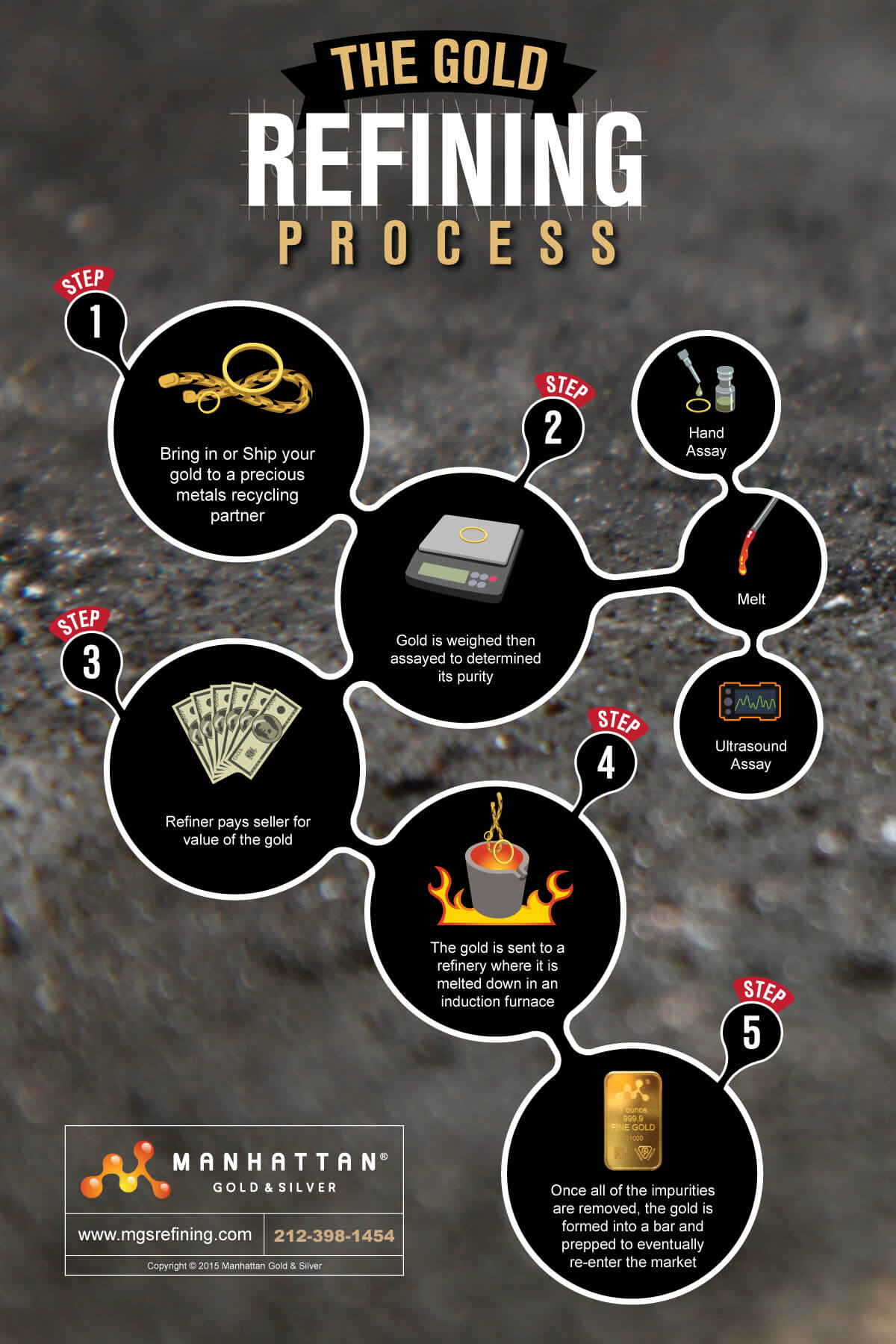

How to Make a Gold Bar by Casting Gold Bullion Ingot

The operation of refining by one of the methods described above is necessary before gold can be exactly valued. When base metals other than copper are present, segregation occurs and the solidified metal is not uniform in composition. The result is that the exact value of the bullion cannot be determined, and the buyer must […]

Gold Refining Methods

The processes used for Gold Refining are as follows: Volatilisation. Oxidation (a) by air blowing or roasting. (b) by “ bessemerising” (c) by nitre. (d) by metallic oxides. (e) by cupellation. Chlorination. Sulphurisation. The use of iron or carbon. The method to be used depends partly on the composition of the bullion, and partly on […]

Gold Melting Furnaces: Key Features and Applications

The furnace used for melting gold bullion is of simple construction. It may be round or square, with walls consisting of an outer layer of ordinary brick and an inner layer, at least 4 inches thick, of the best firebrick. There is often a complete outer casing of iron, which is useful in keeping the […]

How pH Affects Cyanide Decomposition & Use Alkalinity to Preserve Cyanide

Since acidity of the ore causes decomposition of the cyanide, an obvious method of reducing the loss is to add alkali in some form. Before doing this, the free sulphuric acid and soluble salts may be removed by leaching with water, and then a solution of caustic soda or lime is run on to the […]