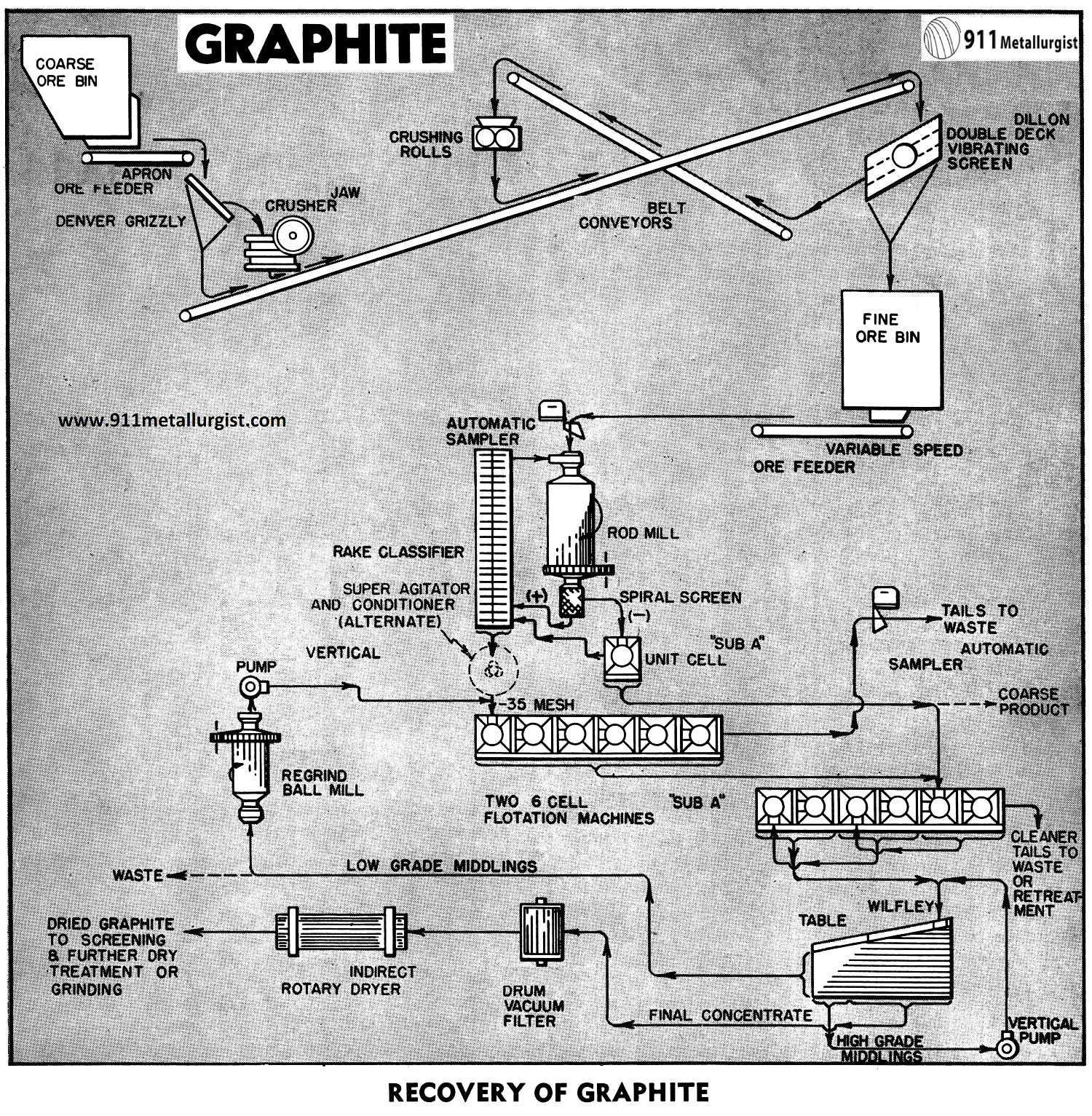

Graphite Beneficiation Process

Graphite is an important industrial mineral. Two types occur in nature, crystalline and amorphus. Crystalline graphite is used principally for crucibles and shaped structures. Amorphus graphite is used extensively in the steel and lubrication industries. In many deposits the two types grade into each other and the ore is of such low grade that beneficiation […]

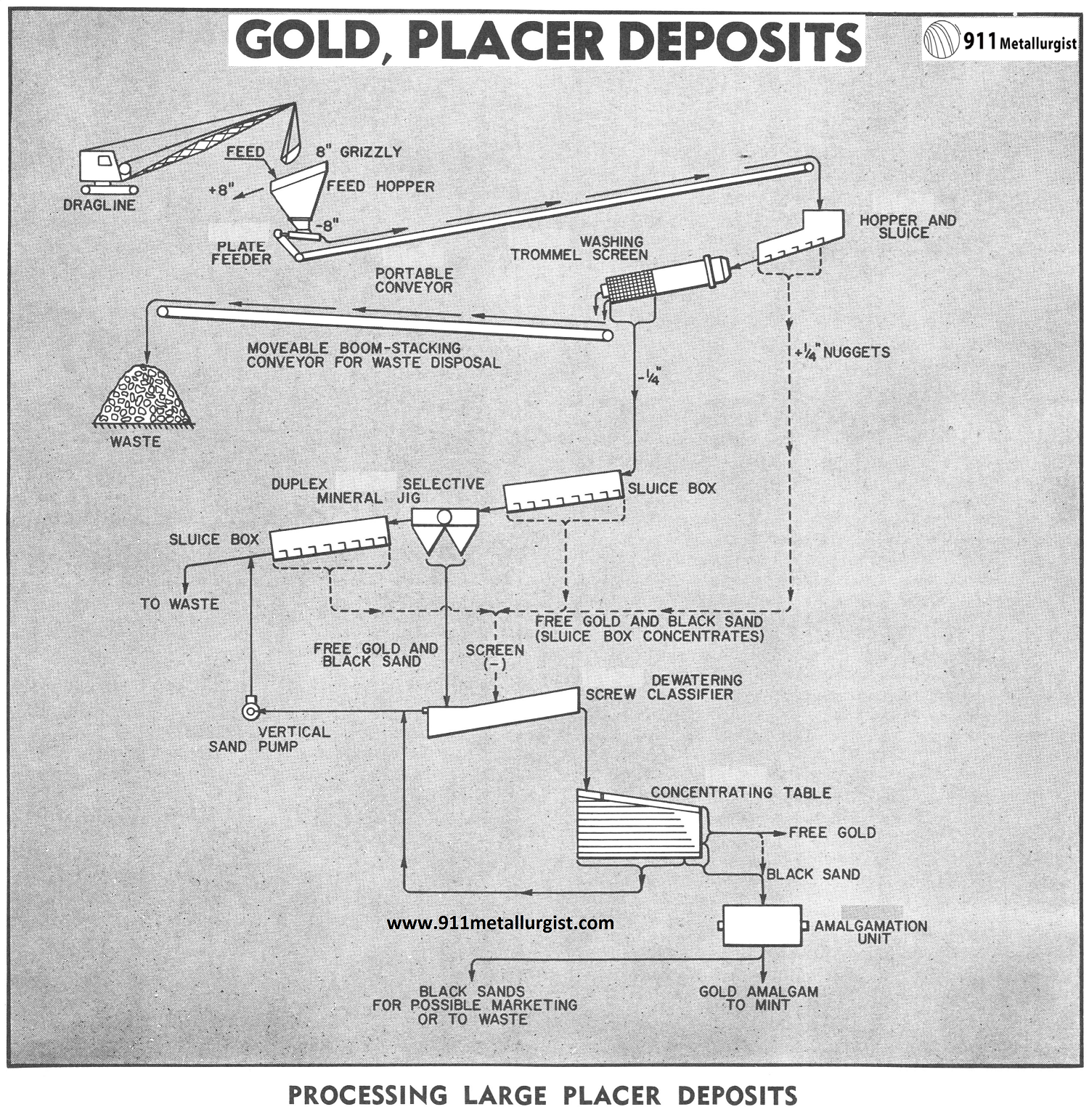

Gold Washing and Gravity Circuit for Placer Gold

The handling of large quantities of gold-bearing gravels is of utmost importance for most successful placer operations. In addition to providing efficient washing and recovery methods, the placer plant should be constructed as a compact unit that can be readily moved. This is an important consideration because the washing and recovery plant should be close […]

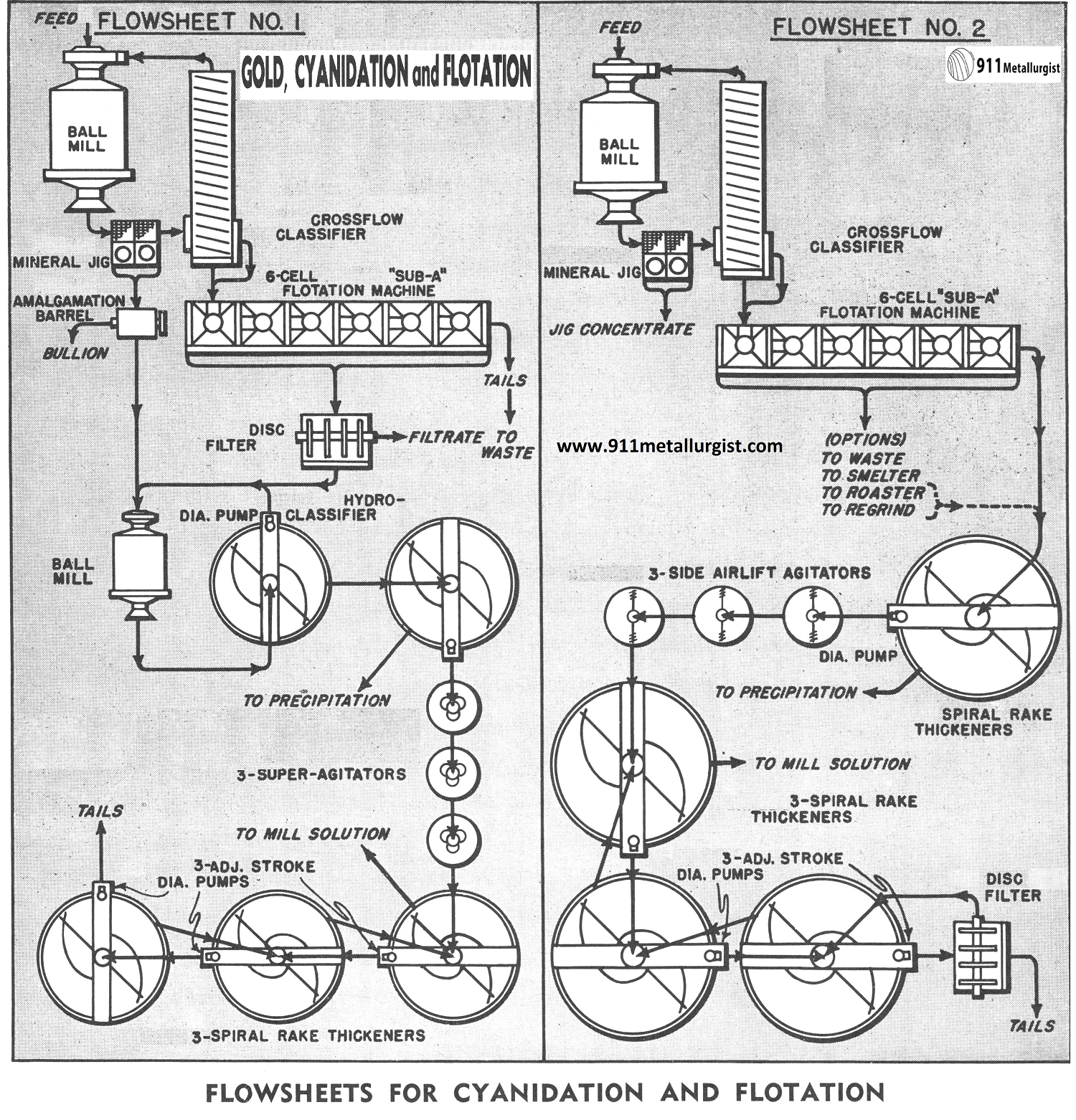

Batch Cyanidation of Flotation Concentrate

The production of gold bullion from gravity or flotation concentrates is often an important economic consideration for an isolated gold mining operation. It is assumed in this case that the coarse free gold has been recovered by the Mineral Jig in the grinding circuit and that the jig concentrate has been amalgamated. This treatment produces […]

Gold Leaching Process

Many opportunities exist throughout the world for small cyanide plants, possibly using a Gold Leaching Process, both for production and pilot operations, especially in areas not easily accessible, and where labor and local costs are on a level for profitable operation. Ores not fully amenable to treatment by amalgamation or flotation processes for the recovery of […]

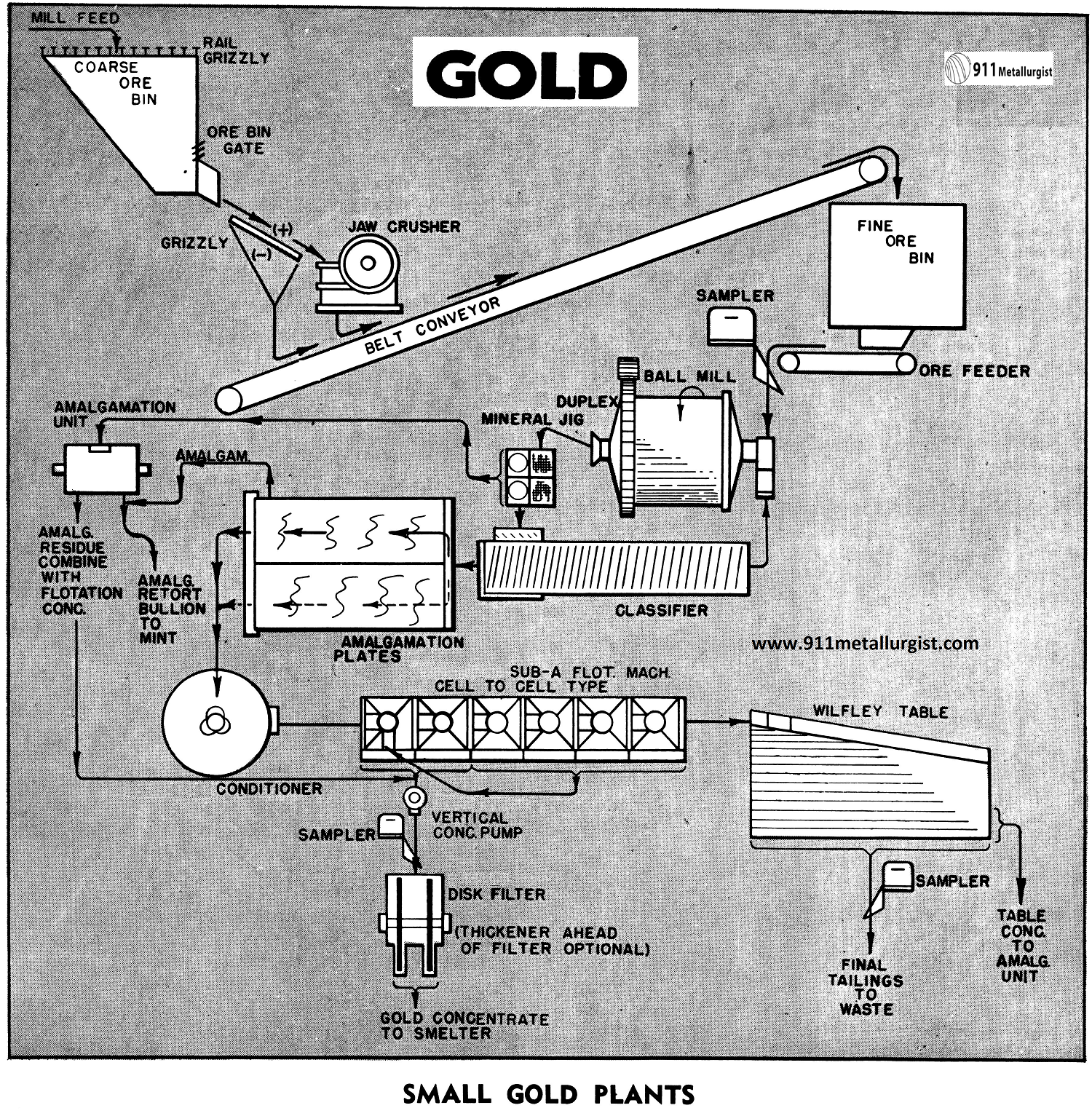

Small Gold Processing Plant

The problem a Small Gold Processing Plant can solve is for the need to to provide a small, relatively simple and inexpensive gold mill that will operate at a reasonable profit with a minimum of supervision. The limited availability of skilled operating personnel, availability of water and local power, high cost of transporting ore and expense […]

Sulphide Gold Ore Treatment by Leaching and Flotation

Problem with gold recovery from sulphide ore: How may a mill get the maximum recovery of gold from a sulphide ore, at the least capital cost and at the same time obtain the highest net return. This latter point is most important. In many cases a gold mill using an all-cyanide flowsheet with fine grinding of […]

Gold and Silver Leaching by Cyanidation

Introduction to Gold and Silver Leaching The cyanide leaching process is the most important method ever developed for extracting gold from its ores. The early development of the process is attributed to a Scotchman, John Stewart Mac Arthur, in collaboration with the Forrest brothers. The method was introduced into South Africa in 1890. From there it spread […]

Flash Flotation with Closed Circuit Grinding

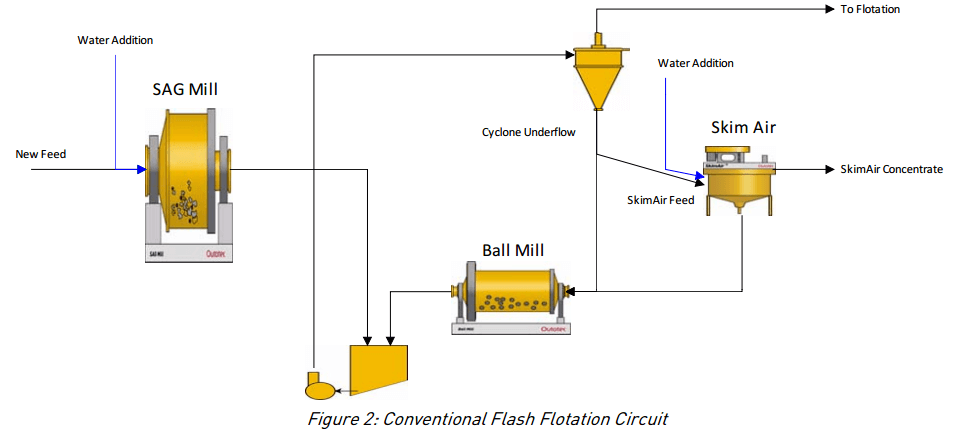

The reason why you need Flash Flotation in a Closed Grinding Circuit relates to “Recovering your mineral as soon as free” which has long been recognized in ore dressing practice. This not only applies to gravity treatment but also to flotation. For this application the Flash Flotation Cell was developed for use in the grinding circuit and […]

Easy Mill Expansion – Float Coarse at Higher Tonnage

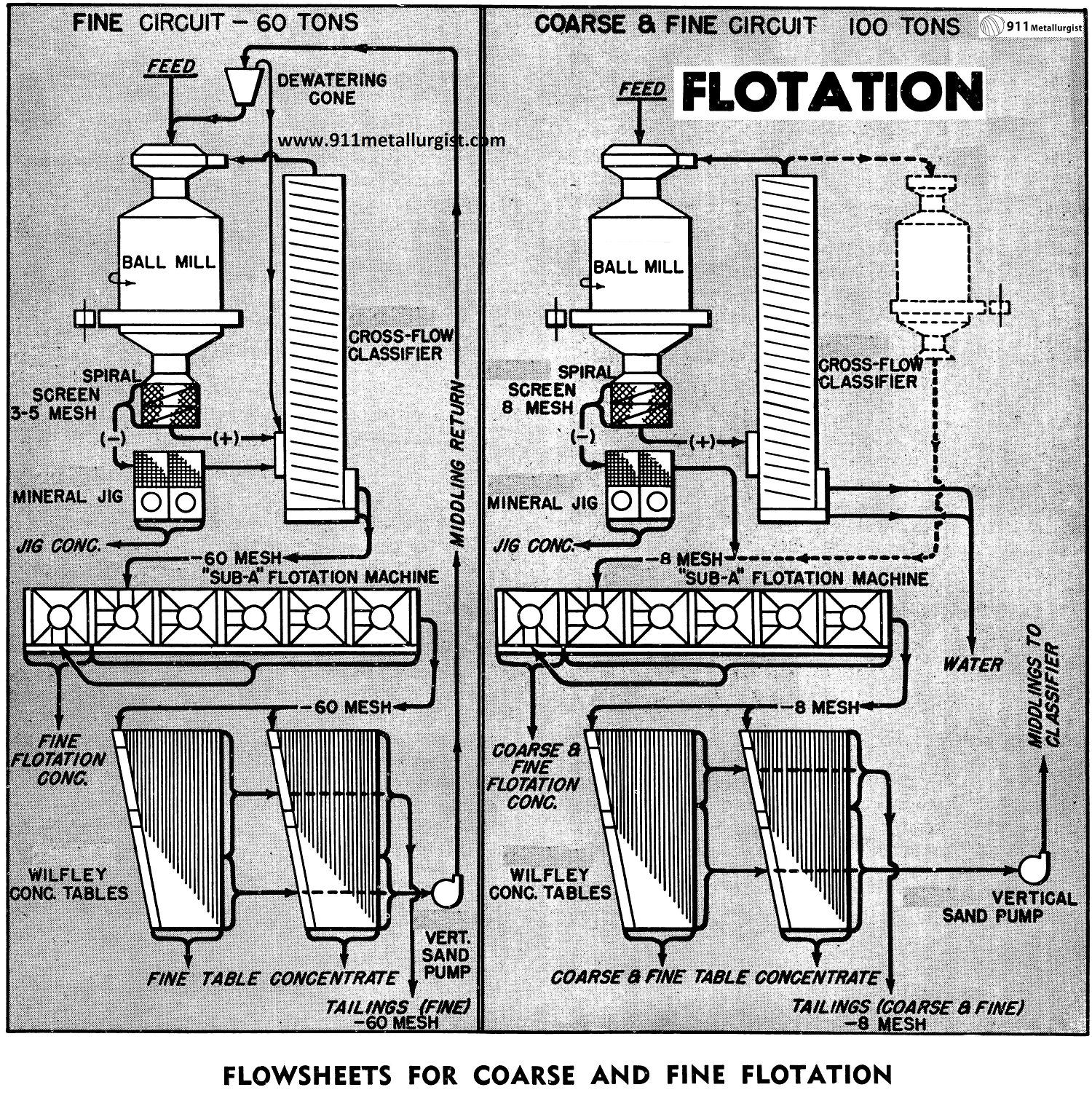

The Problem with Coarse Flotation and Recovery Many flotation plants today are grinding to fine sizes. This means that money is being spent grinding worthless gangue which might be discarded at a coarser mesh. Many plants are treating ores in which the gangue is free at a coarse mesh and where a coarse bulk concentrate […]

Feldspar Beneficiation & Flotation Process

Beneficiation by Flotation of feldspar is well established. It is a simple matter by flotation to remove the contaminating impurities and keep the alumina (Al2O3) content at 19% even on low grade feldspar ores. Dry recovery methods are economically limited to about 17% Al2O3. The problem in feldspar flotation is to recover slime free granular […]