Manganese Ore Processing

The problem involved in Manganese Ore Processing deals with the production of acceptable specification grades of manganese concentrates at a maximum recovery of the total manganese from ores having variable characteristics. The flowsheet provides for both gravity and flotation with a maximum recovery of the manganese values in a coarse size in the most economical […]

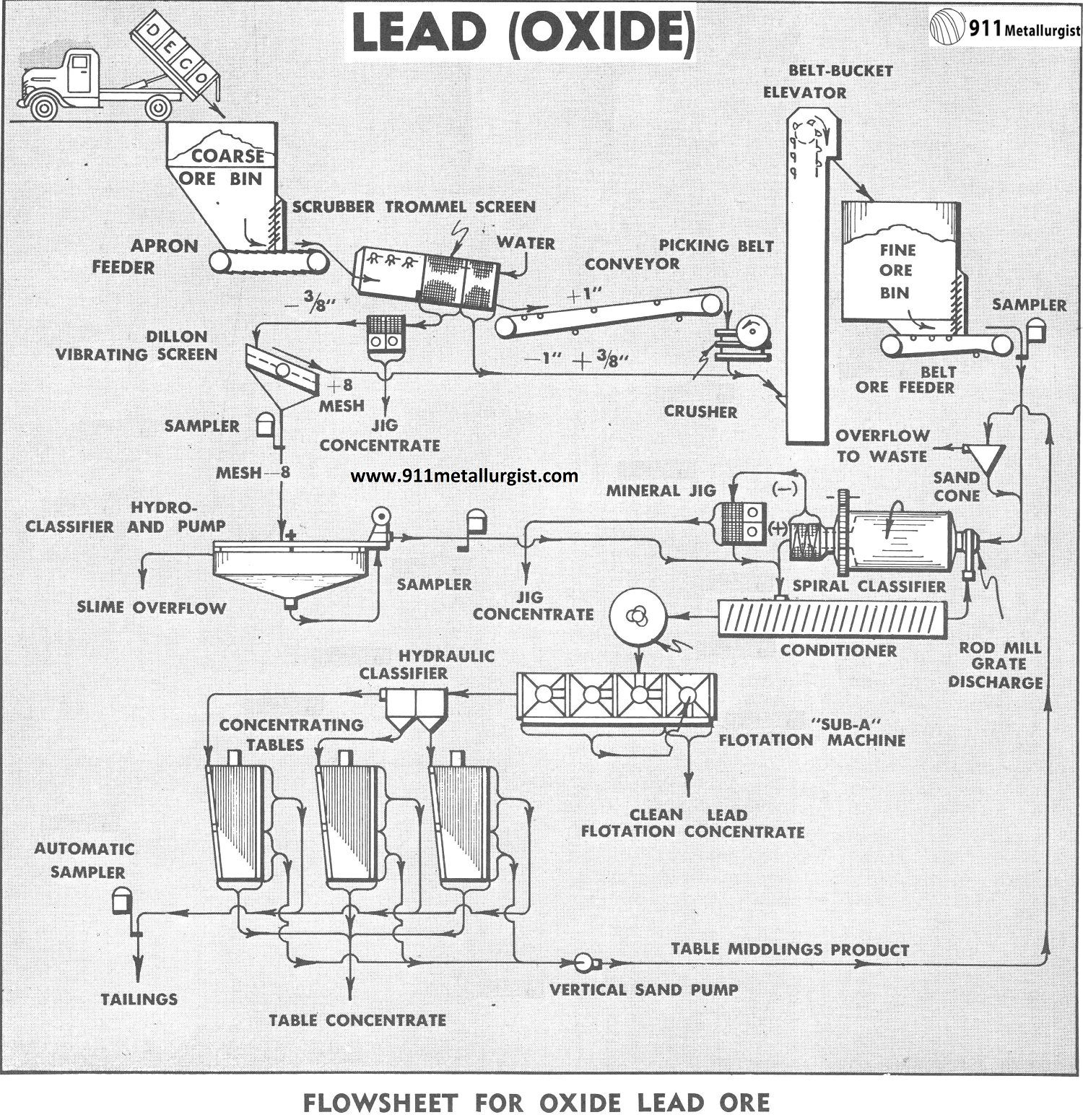

Oxide Lead Treatment & Extraction by Flotation & Gravity Methods

The problem of treating oxidized lead ores and many other oxides is complex due to the nature of the ore and to the soft, sliming characteristics of the lead oxides. These ores are usually of a sticky nature, being high in primary slimes, and are difficult to handle and feed. The lead carbonate as cerussite […]

Galena – Sphalerite Flotation & Separation Method

The problem of treating oxidized lead-zinc ores for the production of high-grade lead zinc flotation concentrates is a complex problem due to the nature of the ores and to the soft sliming characteristics of the lead and zinc minerals. The ore for treatment is a lead-zinc carbonate ore in a mixed siliceous-lime carbonate gangue. The association of […]

Gold Leaching Equipment, Circuits & Process Plants

In Leaching for Gold, there is often a tendency to overlook or minimize the importance of the small mine. The small mine of today may develop into the large mine of tomorrow. Under proper management and financing it has as good a chance of yielding a profit as the larger property. Unfortunately large capital is […]

Flotation Machine

The flotation process is widely used for treating metallic and non-metallic ores and in addition, it is receiving an ever widening application in other industries. A greater tonnage of ore is treated by flotation than by any other single process. Practically all the metallic minerals are being recovered by the flotation process and the range […]

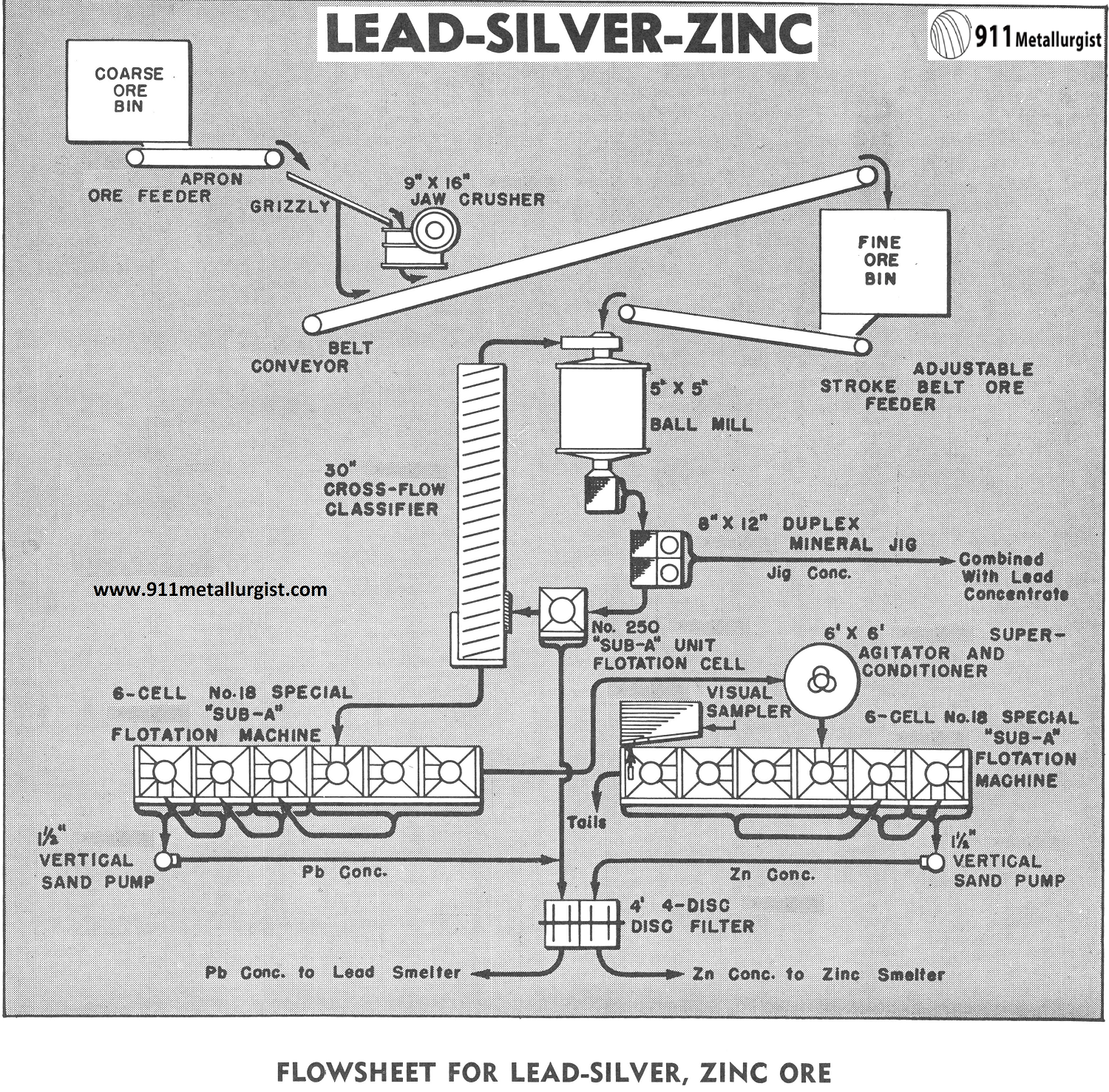

Silver Lead Zinc Ore Processing Method using Flotation

Sulphide ore of lead and zinc containing considerable silver was submitted for testing with the purpose of determining a flowsheet for the production of separate lead and zinc concentrates for marketing at their respective smelters. It is necessary to recover as much silver as possible in the lead concentrate as a higher return for this […]

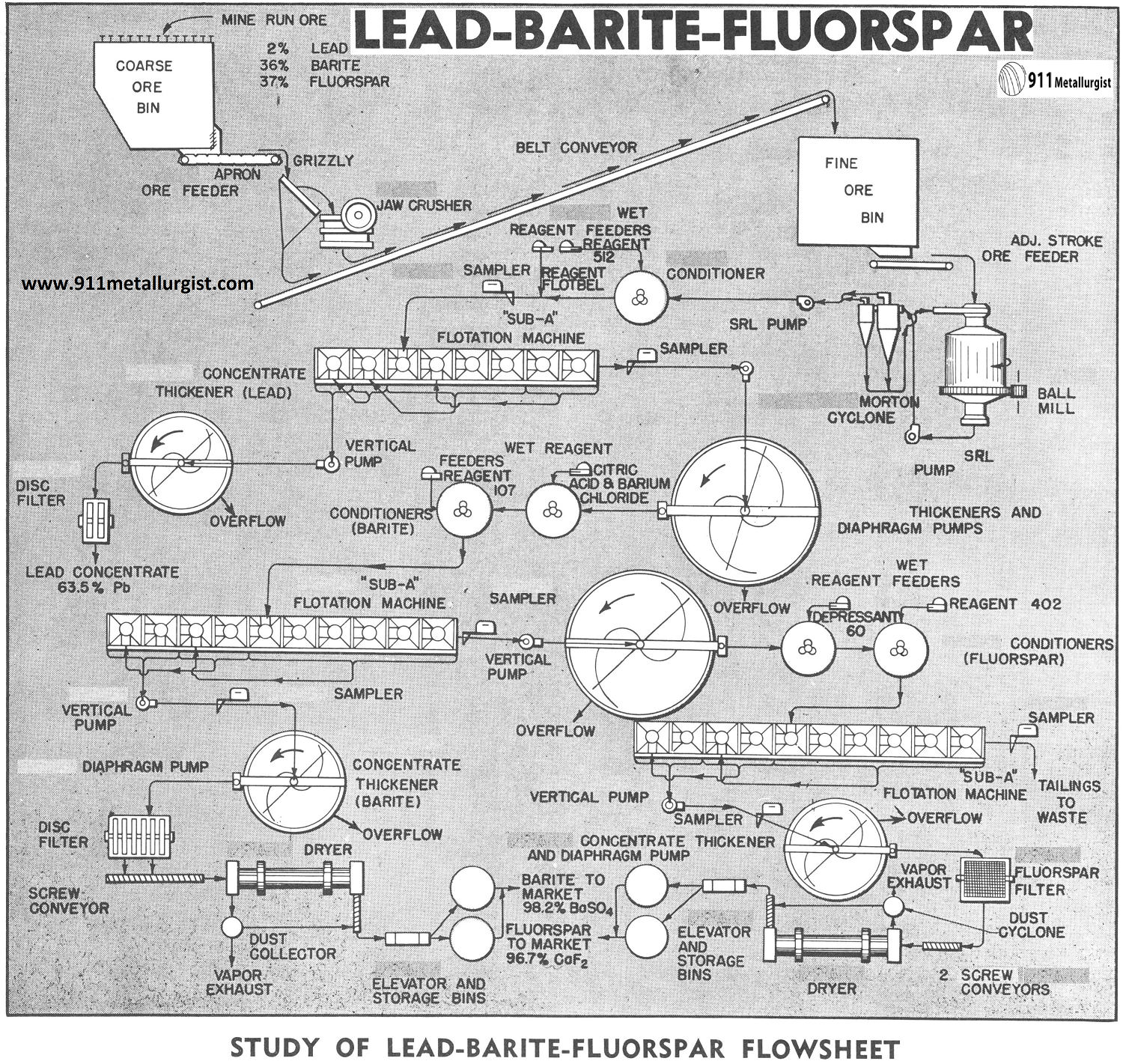

Lead Barite Fluorspar Separation Method

The concentration of fluorspar ores by flotation is well established but the treatment of lead-barite-fluorspar ores has long been recognized as a difficult process generally resulting in unacceptable concentrates with relatively poor recoveries. Intensive research on this problem is continually being conducted to develop favorable reagent combinations and conditions suitable for treating such ores. The […]

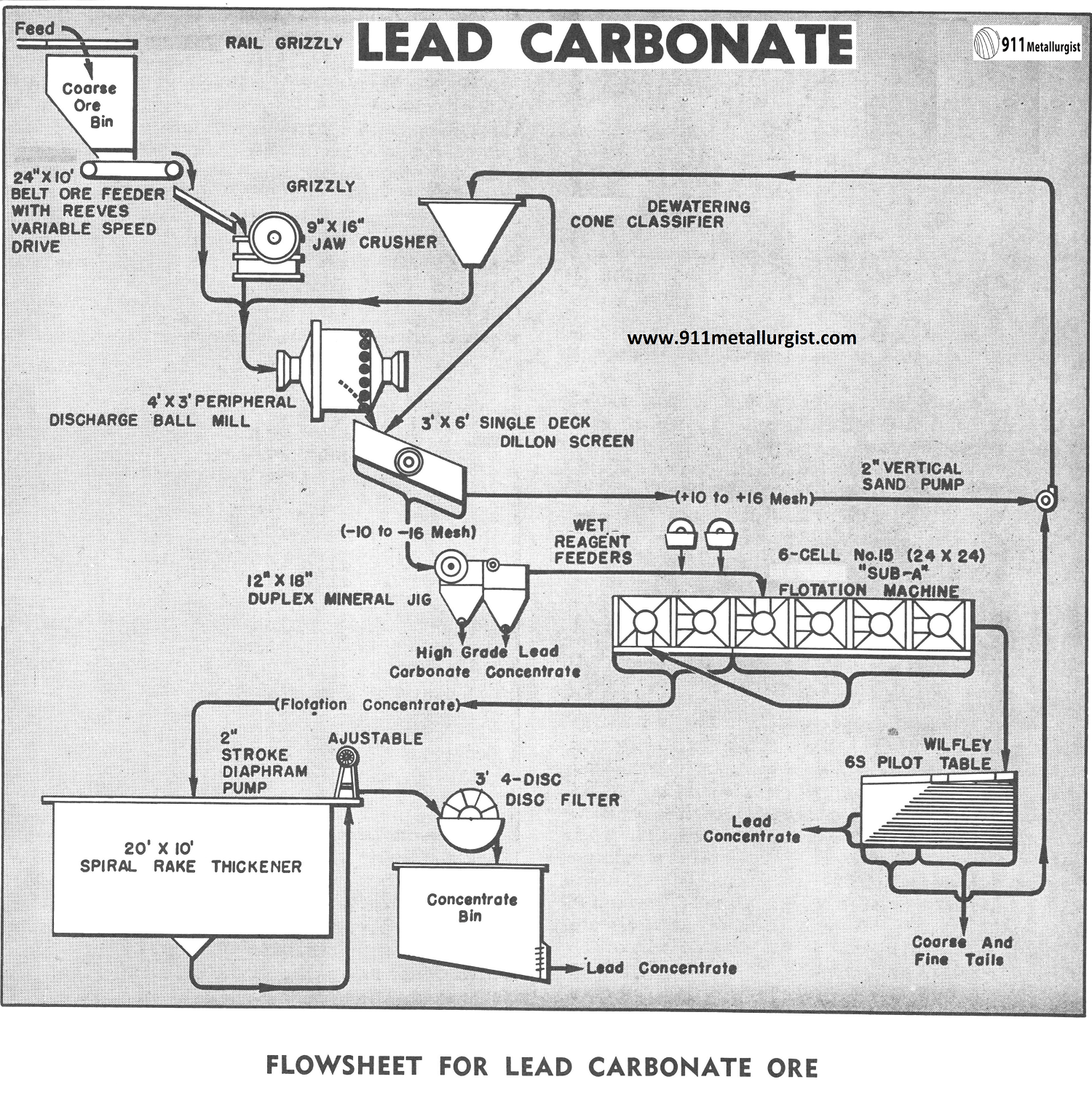

Lead Carbonate Beneficiation by Gravity and Flotation

Treatment of oxidized lead ores (Cerussite) has long been recognized as a difficult process often resulting in low grade concentrates and low recoveries. Surface oxidation on galena ores has resulted in high tailings losses. The difficulty in treating oxidized lead ores by gravity methods is due to the softness of the oxidized lead minerals. During […]

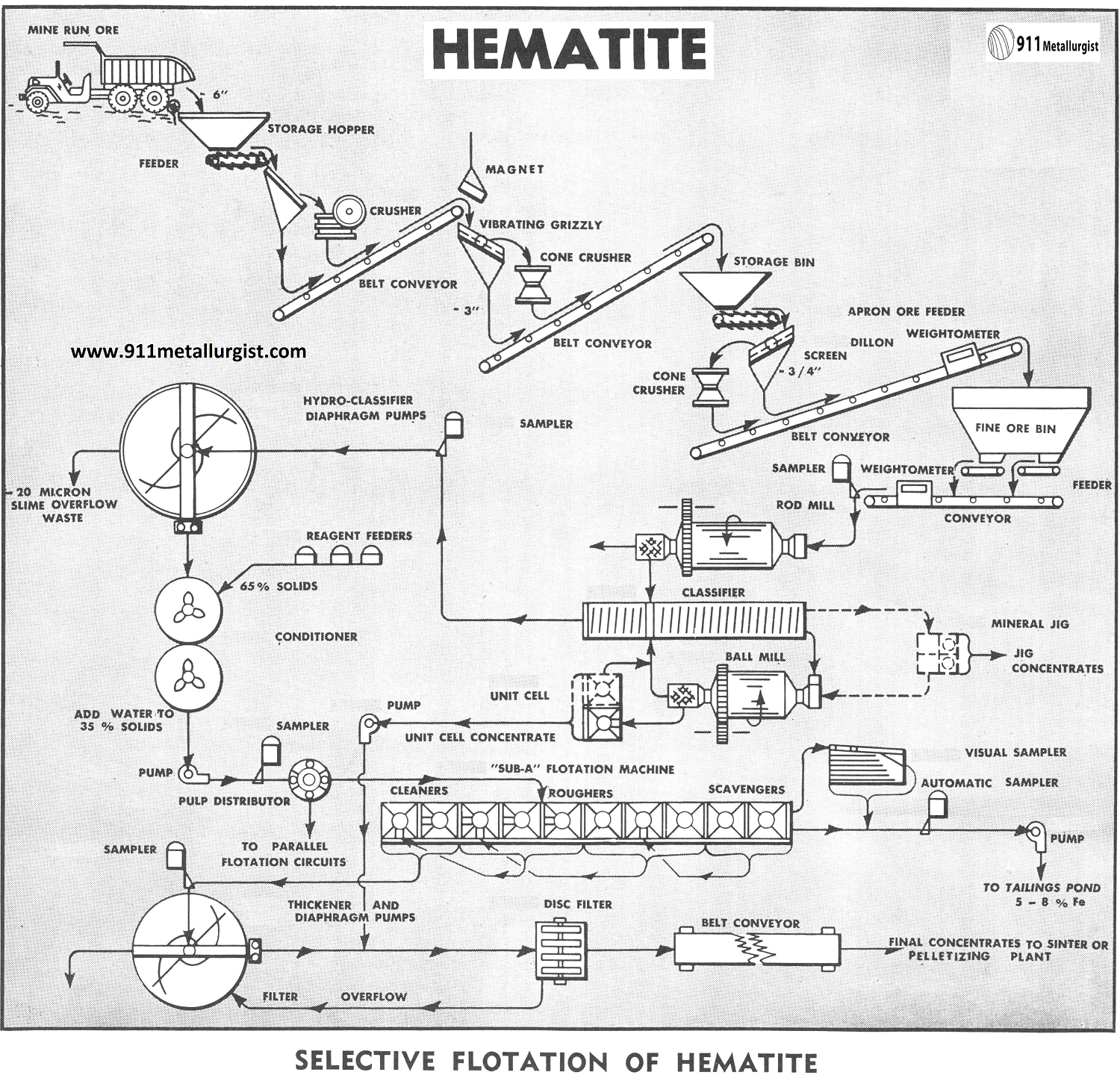

Hematite Processing by Flotation

Direct shipping of high grade iron ore, because of depletion or partial depletion of reserves, or high costs of operation has forced operators to use some means of beneficiation to produce an acceptable product with the lower grade iron ore reserves. Deposits of comparatively lower grade iron ore that remain relatively untouched or by-passed, are […]

Single & Double Stage Grinding Circuits

The comparison between single stage and double stage grinding has received much attention in the past few years. In order to submit information for use of mill operators, we have prepared comparative flowsheets for 50 Ton, 100 Ton, 200 Ton, 350 Ton and 550 Ton/24 hour plants, showing both single and two-stage grinding in typical […]