Design Flotation Plant

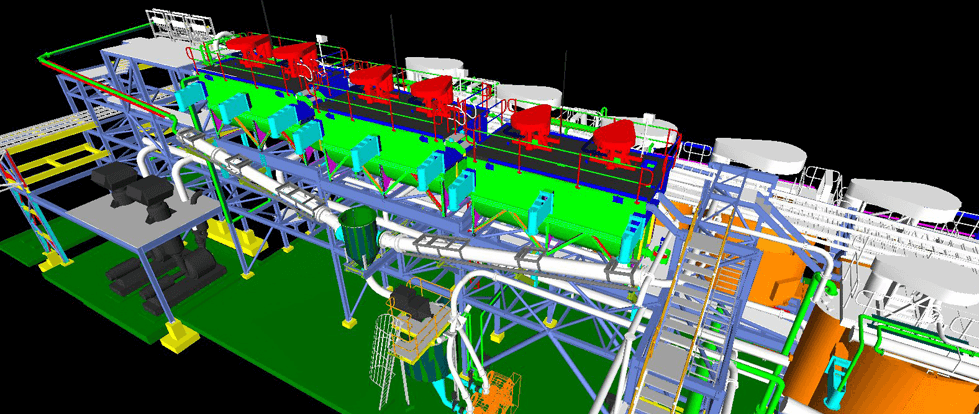

Design Study for 400-Ton per Day Flotation Plant The sulphur mill was designed for best adaptation to the mill site available. The design provided for simplicity of construction and final operation, and full usage of construction items available. Process FLOWSHEET The flowsheet was based on laboratory tests wherein troublesome factors were eliminated ahead of design and construction. The […]

Tin Beneficiation Process

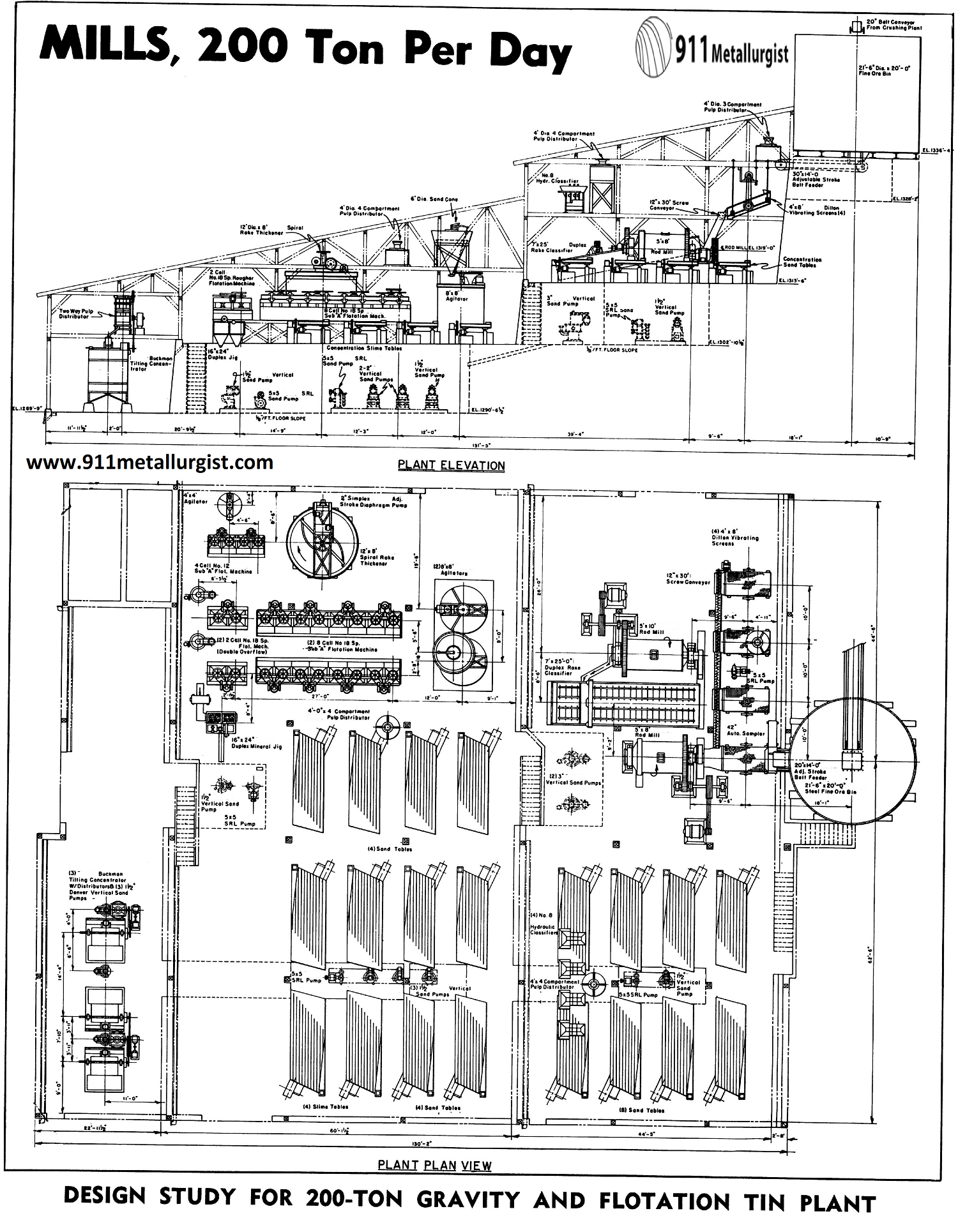

The scarcity of both skilled construction and operating labor in the region, caused the customer to under-score the terms “fool-proof” and “simplicity” in the instructions for the design of this 200 ton tin Beneficiation process plant. Flowsheet The tin process flowsheet was developed by laboratory tests which clearly indicated the method of treatment to give […]

Small Gold Leaching Circuit Design

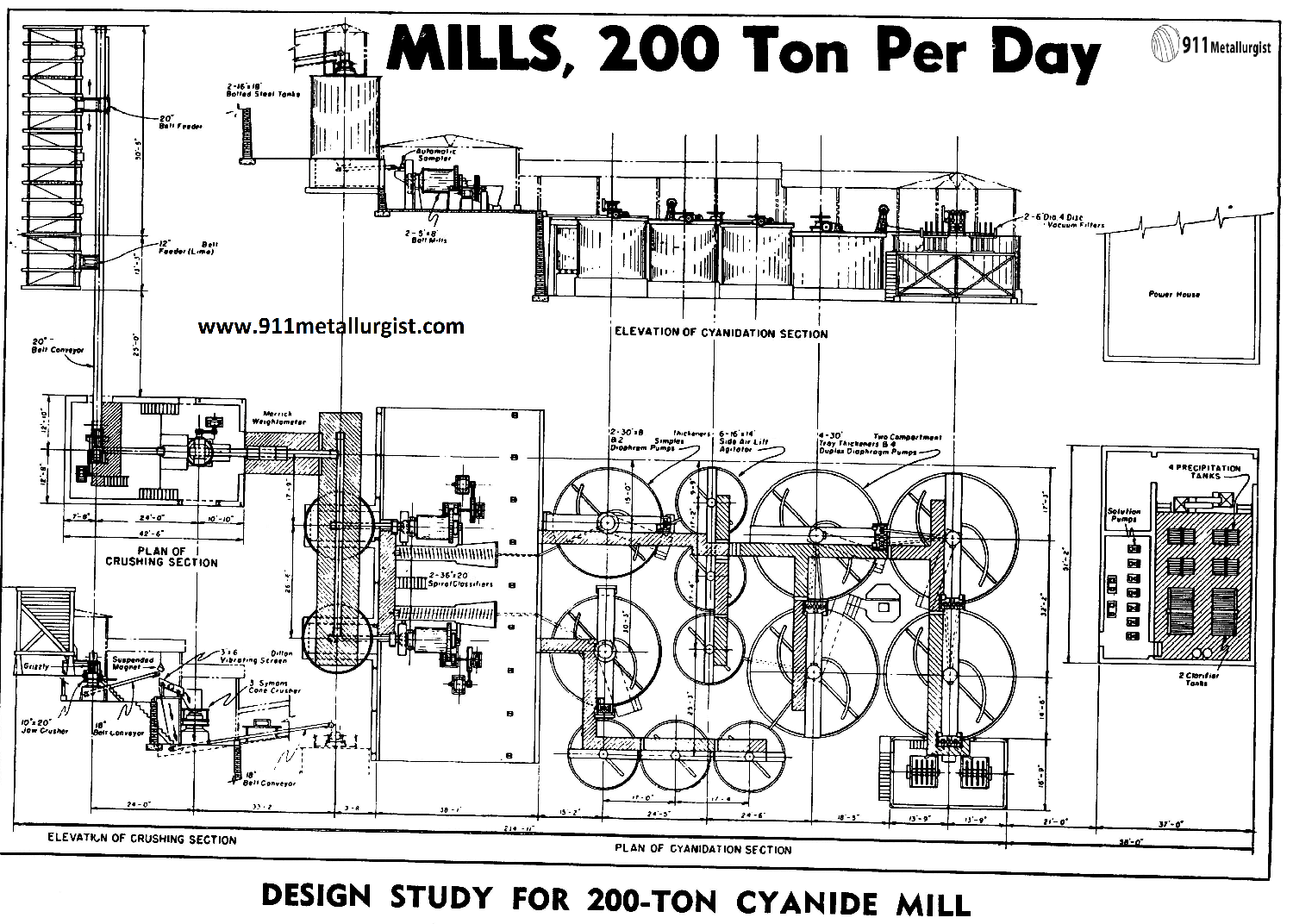

The gold cyanide leaching mill site is centrally located with respect to the mine, water supply and improved highway. This selection reduced both the length of the haulage road from mine to mill and main water supply line to a minimum. The location provided a sloping mill site, adequate tailings disposal area, housing space for […]

Portable Mineral Processing Plant – Gold & other Metals

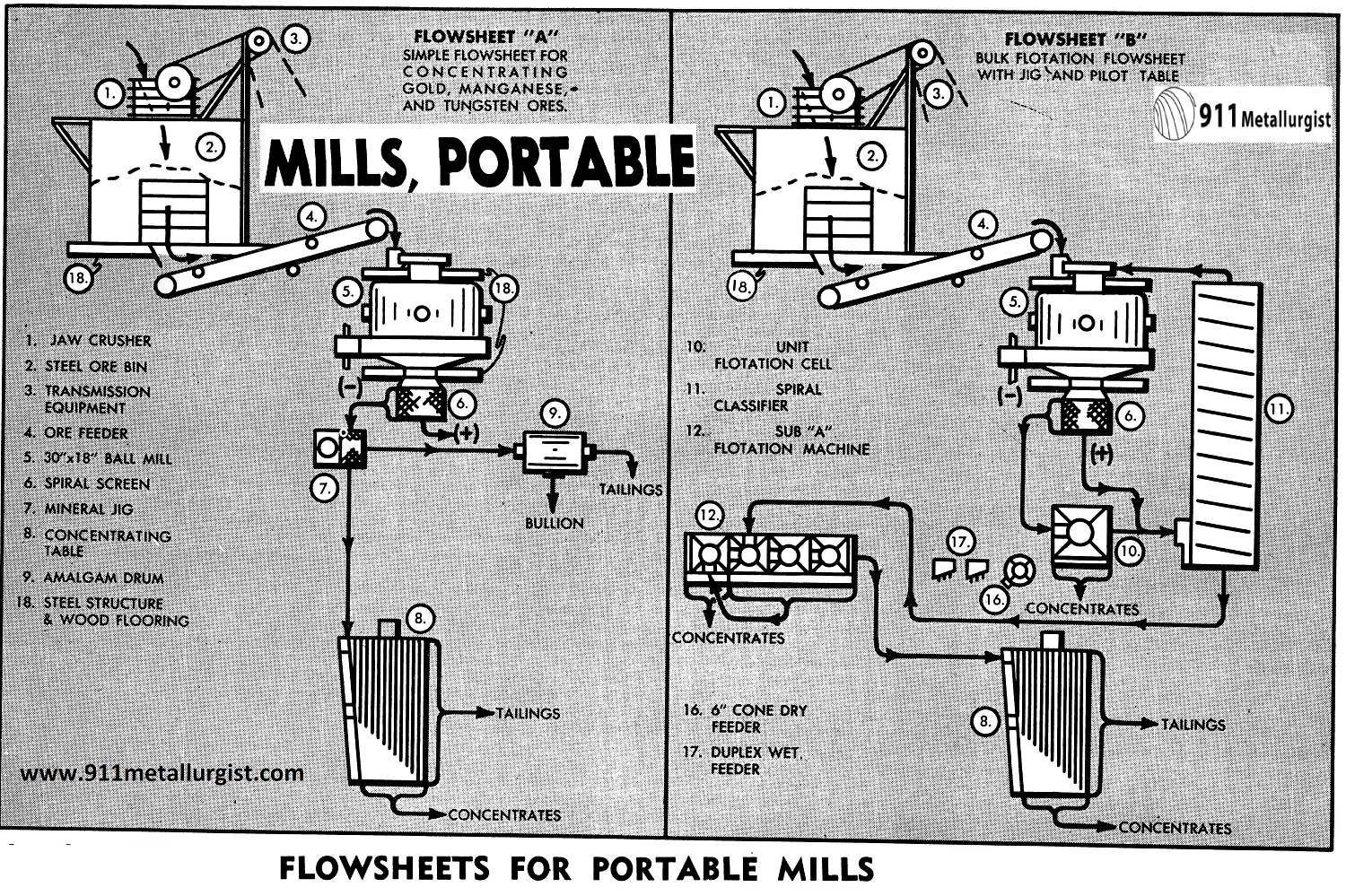

Much interest is being shown by both small operators and big mining companies in small portable and semi-portable milling plants. The small operator, perhaps lacking an extensive ore deposit or finances, must rely on a layout low in initial cost. The bigger mining companies are interested in these small plants—because they can economically prove certain ore […]

Mica Recycling from Scrap

The concentration of mica is an unusual problem due to sheet-like, flaky structure of the minerals. Premium grades of mica demand a sufficiently high price that the ore can be hand-sorted and trimmed. However, the “punch” and “scrap” mica does not demand such handsome prices, so a method of concentration must be used. This system […]

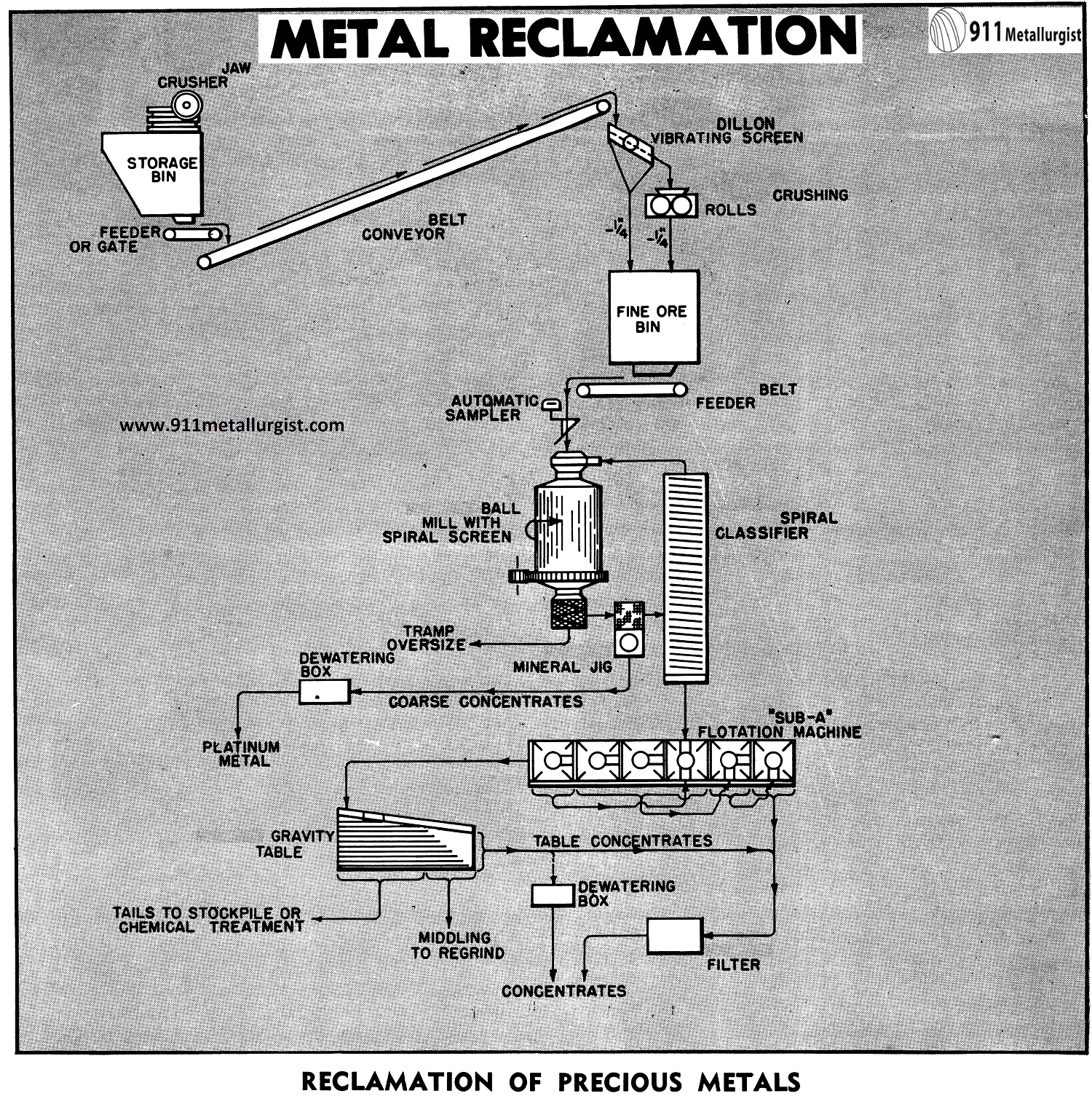

Recycling Gold from Scrap Metal: Process and Equipment

During the manufacture of fiberglass the platinum-rhodium bushings used for the extrusion of the fiberglass tend to vaporize at high temperatures and the metal is deposited on the refractory brick of the glass furnace. Eroded precious metals from other glass-making equipment may also be present. The economics of the process require a flowsheet which will […]

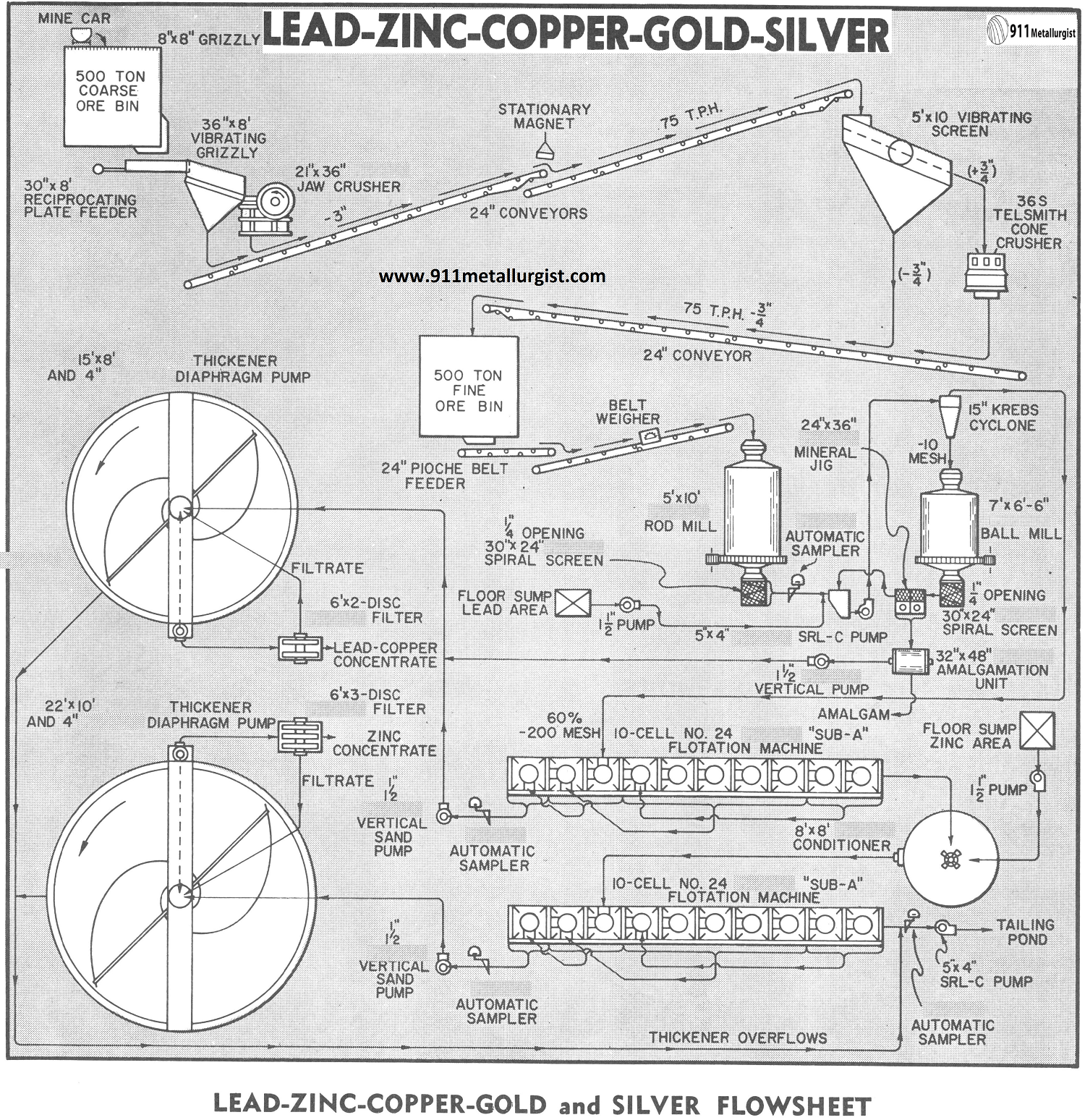

How to Process Copper Lead Zinc Ore with Gold and Silver by Flotation

The flowsheet in this study was designed to treat 500 tons per day of a complex base metal ore containing gold and silver values. The presence of free gold offers opportunity to recover these values in the grinding circuit so that the gold could be amalgamated, and marketed directly to the mint. The ore as […]

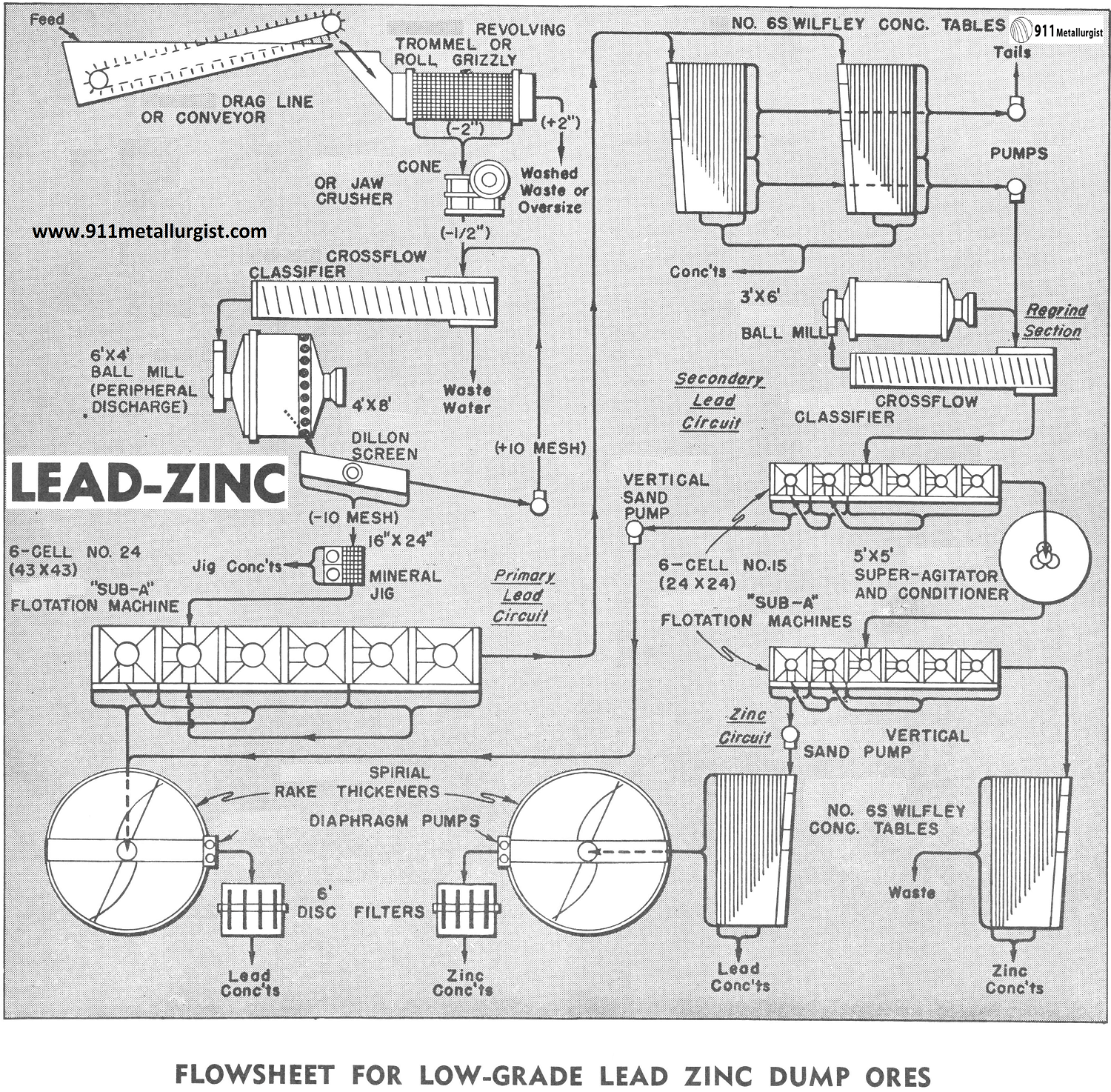

How to Process Low-Grade Lead Zinc Ore by Flotation

The flowsheet above was designed to treat economically approximately 200 tons in 24 hours of a low-grade dump ore containing lead and zinc values as well as some silver in both sulphide and oxide form. Due to varying specific gravities of the values, gravity concentration in addition to flotation was indicated. As is common in many […]

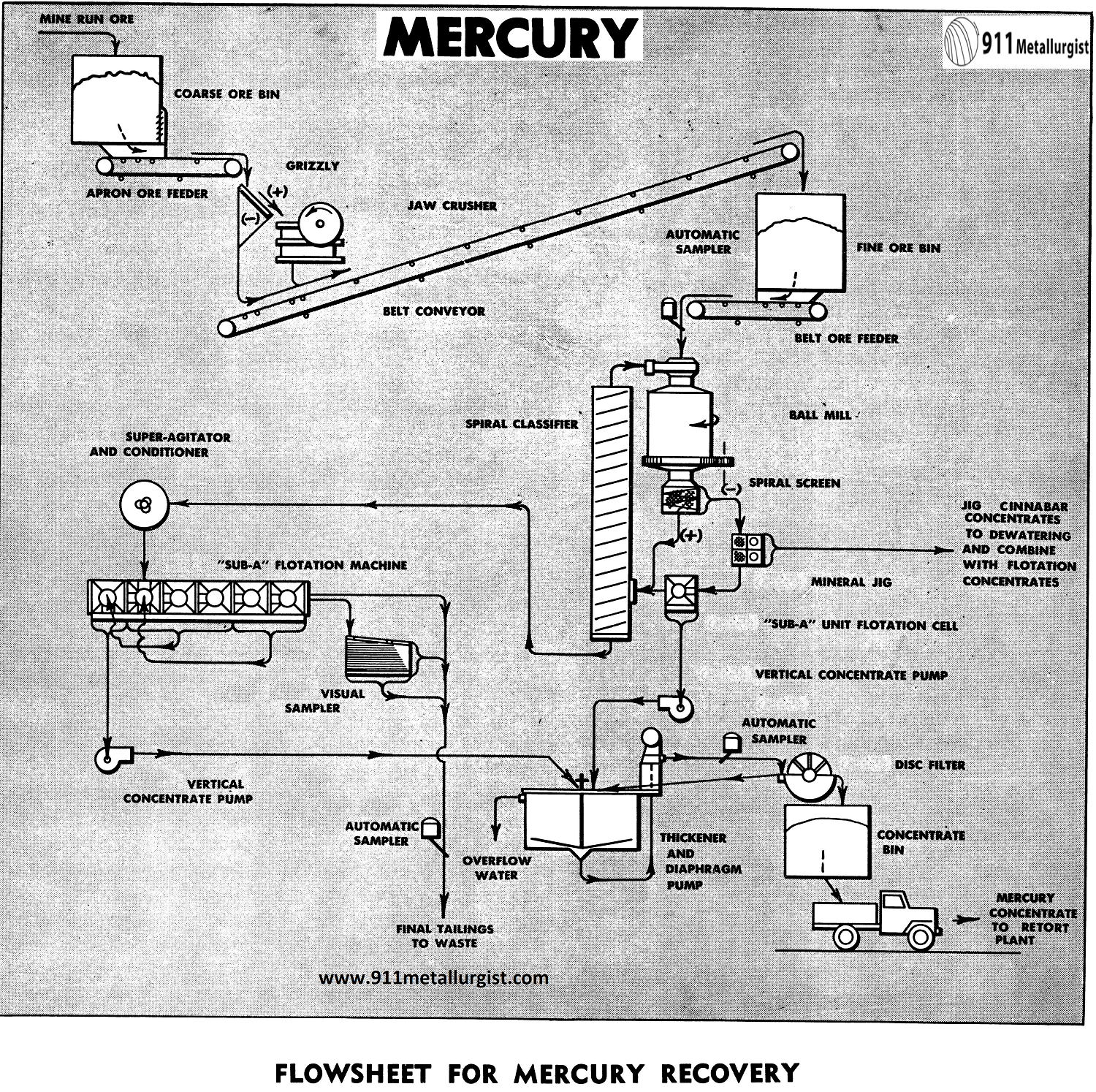

Mercury Ore Processing

The concentration of low grade cinnabar, HgS, with a specific gravity of 8.0-8.2 is effectively accomplished by gravity and flotation methods. Cinnabar ores of relatively high mercury content can be retorted directly to expel the sulphur and condense metallic mercury, but for lower grade ores, preliminary concentration is advisable to reduce the tonnage for retorting. […]

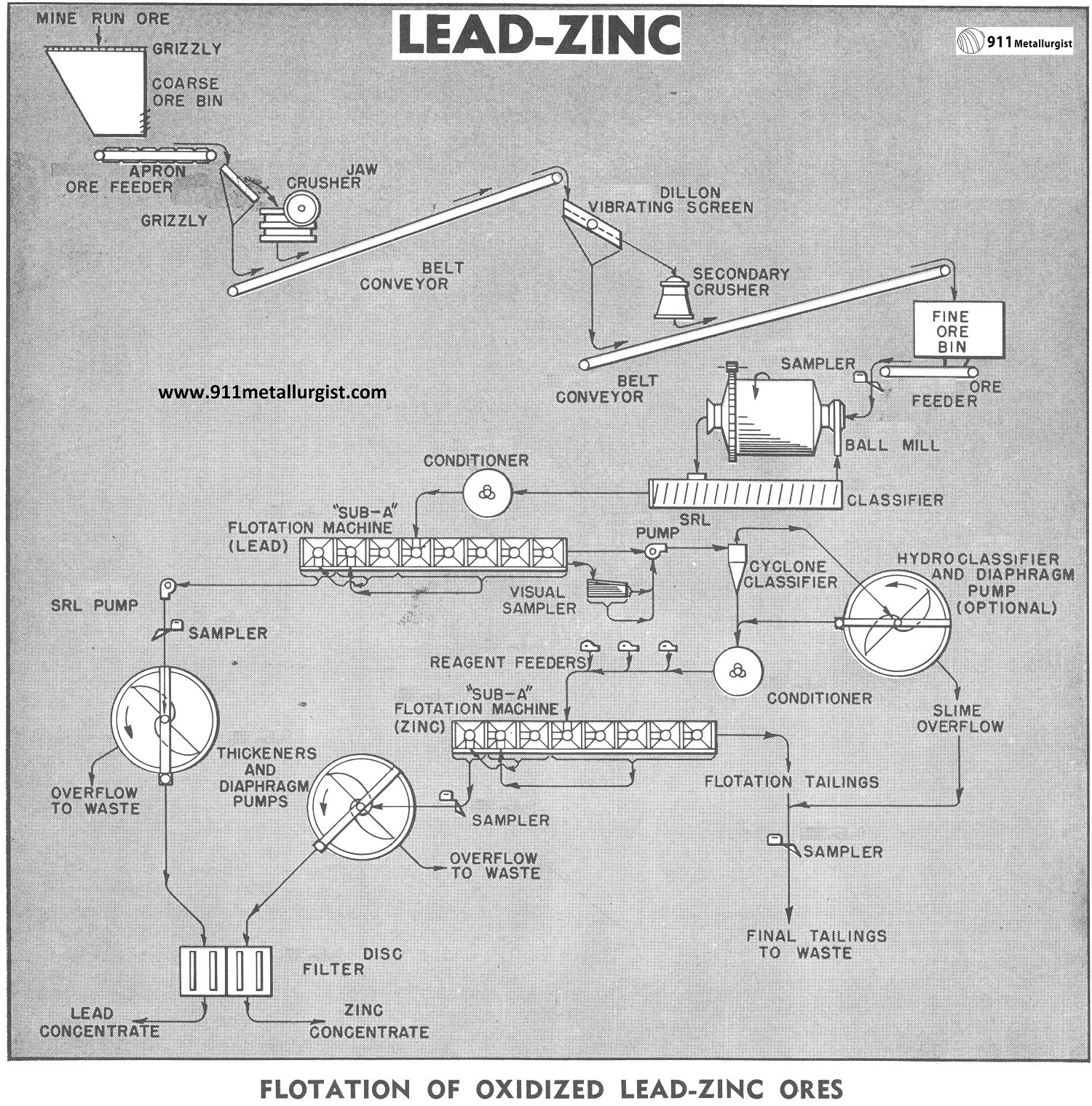

How to Process Oxidized Lead-Zinc Ore by Flotation

The problem of treating oxidized lead-zinc ores for the production of high-grade lead zinc concentrates is a complex problem due to the nature of the ores and to the soft sliming characteristics of the lead and zinc minerals. The ore for treatment is a lead-zinc carbonate ore in a mixed siliceous-lime carbonate gangue. The association of […]