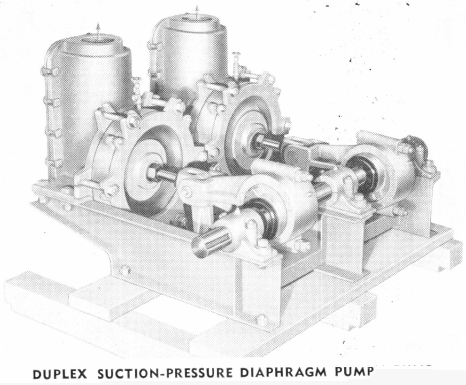

Suction-Pressure Diaphragm Pumps

Suction-Pressure Diaphragm Pump Working Principle and Operations Each Suction-Pressure Diaphragm Pump consists essentially of a pump bowl, in a vertical position, with one rubber diaphragm on the ¾” size and two molded rubber diaphragms on the larger sizes, mounted on one side of the pump bowl. The pump bowl has two valves; the intake, or lower […]

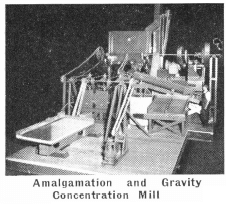

Portable Gold Processing Plant

Portable Gold Amalgamation Plant Free milling gold and silver ores are efficiently and economically treated in Amalgamation Mills. These mills are often used in the early stages of development of free milling gold properties to recover the main portion of the gold with a simple, inexpensive flowsheet. Later a more comprehensive installation can recover the […]

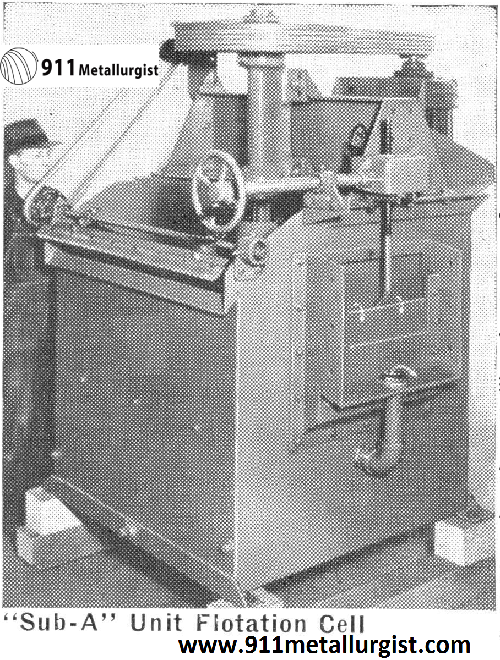

Flash Flotation Cell and Flotation Banks

Flash Flotation Cell The “Sub-A” Flash Flotation Cell, when installed in the circuit between the ball mill and classifier, makes possible the quick recovery of coarse free mineral, which is a vital factor in economic mill operation. Slime losses from overgrinding are reduced to a minimum with the use of the “Sub-A” Unit Flash Flotation […]

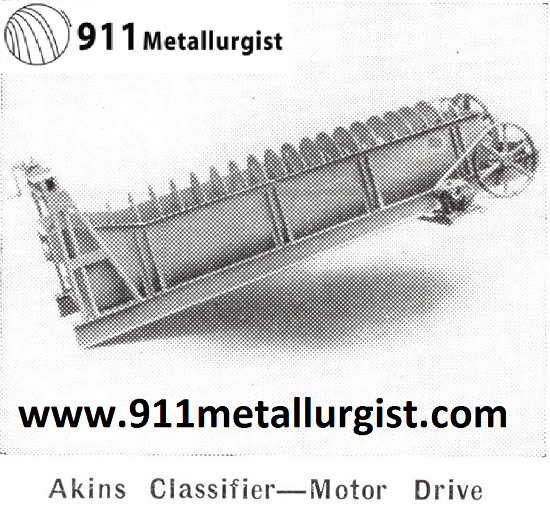

Types of Classifiers in Mineral Processing

Spiral Classifier In mineral processing, the Akins AKA spiral or screw Classifier has been successfully used for so many years that most mill operators are familiar with its principle and operation. This classifier embodies the simplest design, smallest number of wearing parts, and an absence of surge in the overflow. It separates coarse and fine […]

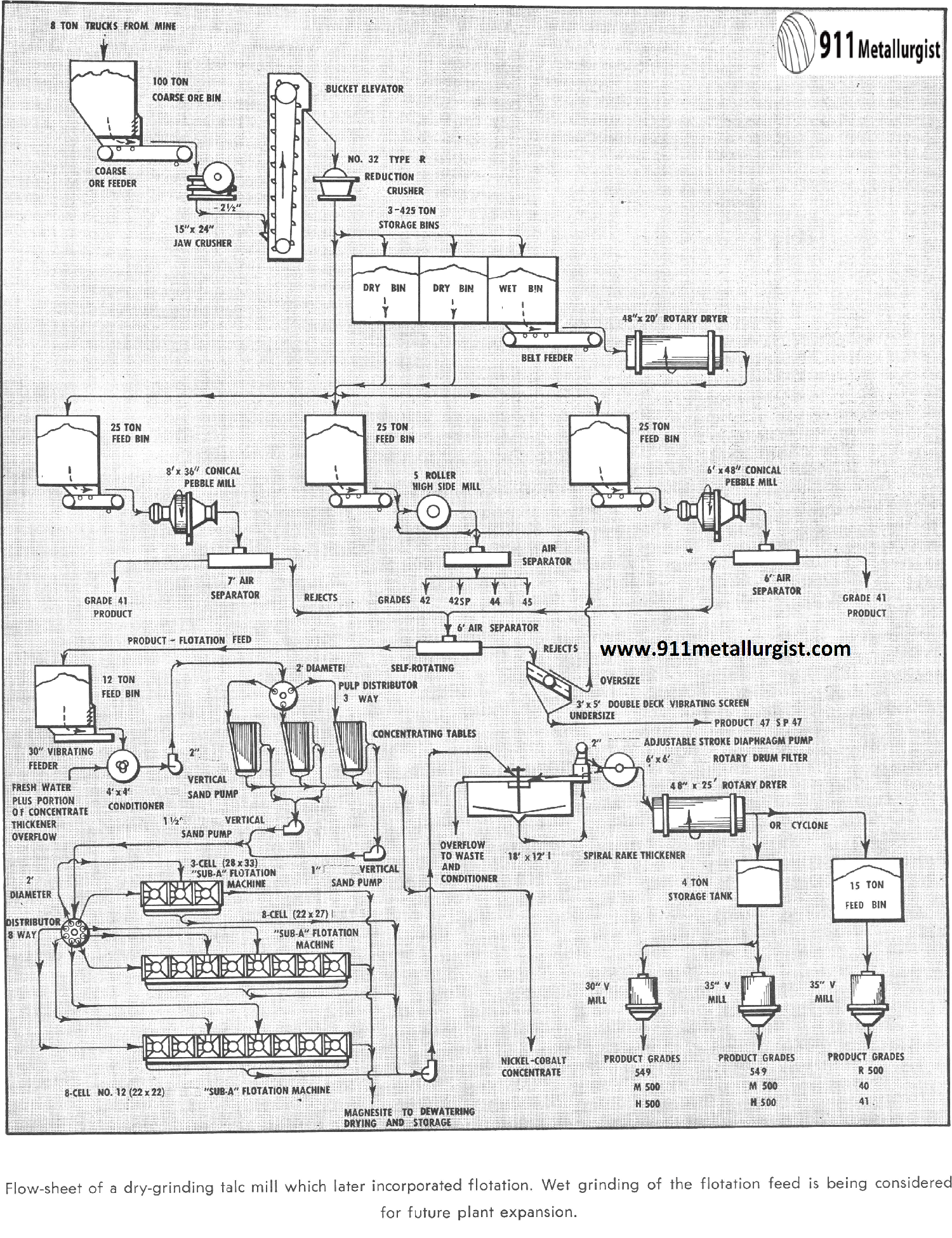

Talc Beneficiation Process – Flotation

Talc Market Specifications Talc has a wide variety of uses and markets, specifications for which call for certain standards of grain size, shape, color, chemical and mineral composition, weight per unit volume, oil absorption and hardness. The paint industry is by far the largest user of talc, but the roofing, ceramics, paper, rubber, cosmetics, textile […]

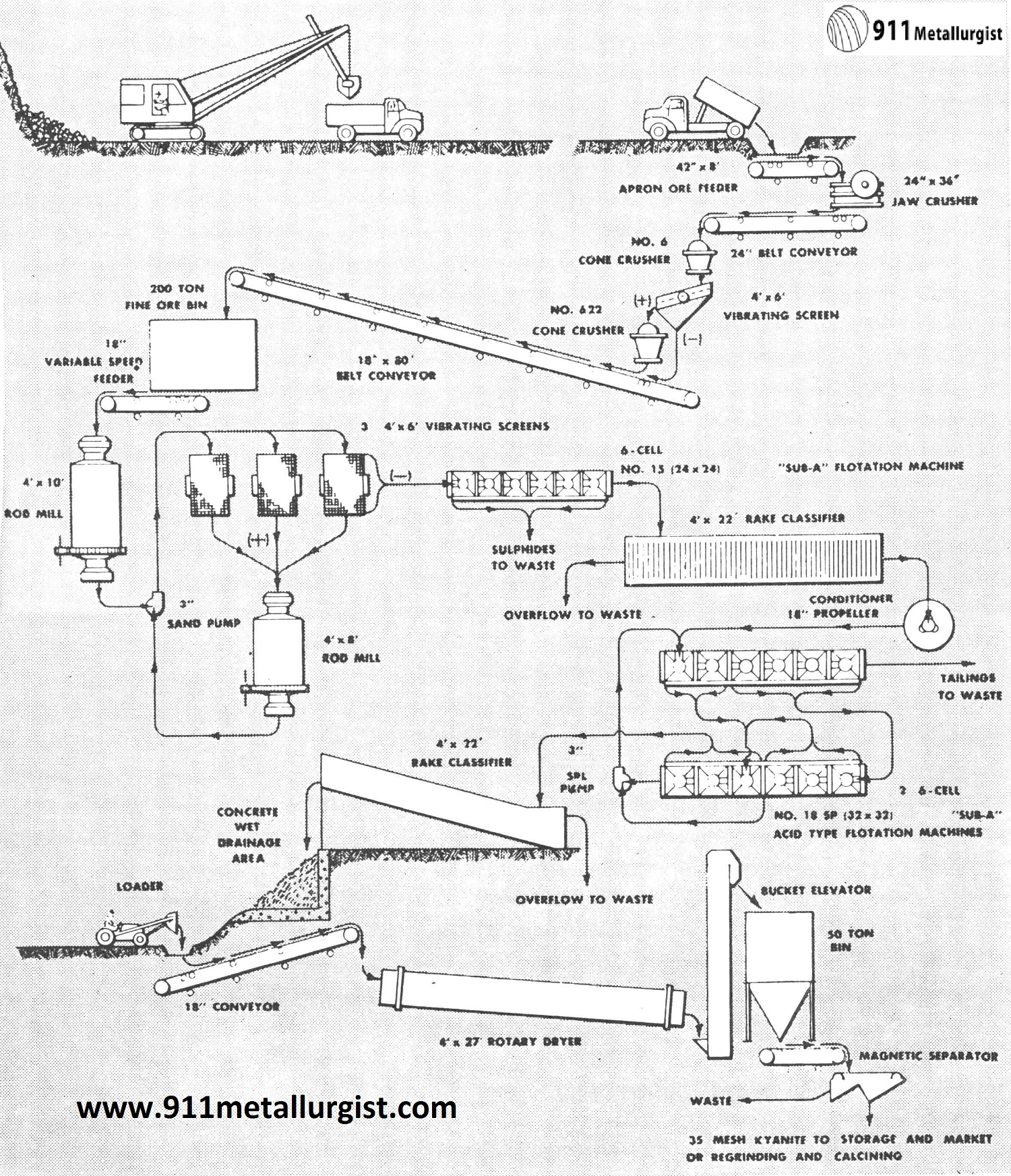

Kyanite and Sillimanite Beneficiation Process

Kyanite and Sillimanite Production Problems The number of commercial deposits is limited and occurrence in schists with iron oxide necessitates concentration to remove iron oxide and excessive silica. Some of the ores have sulphides present, such as pyrite, which must be removed ahead of the kyanite flotation section. Generally, acid circuits are necessary in kyanite flotation. […]

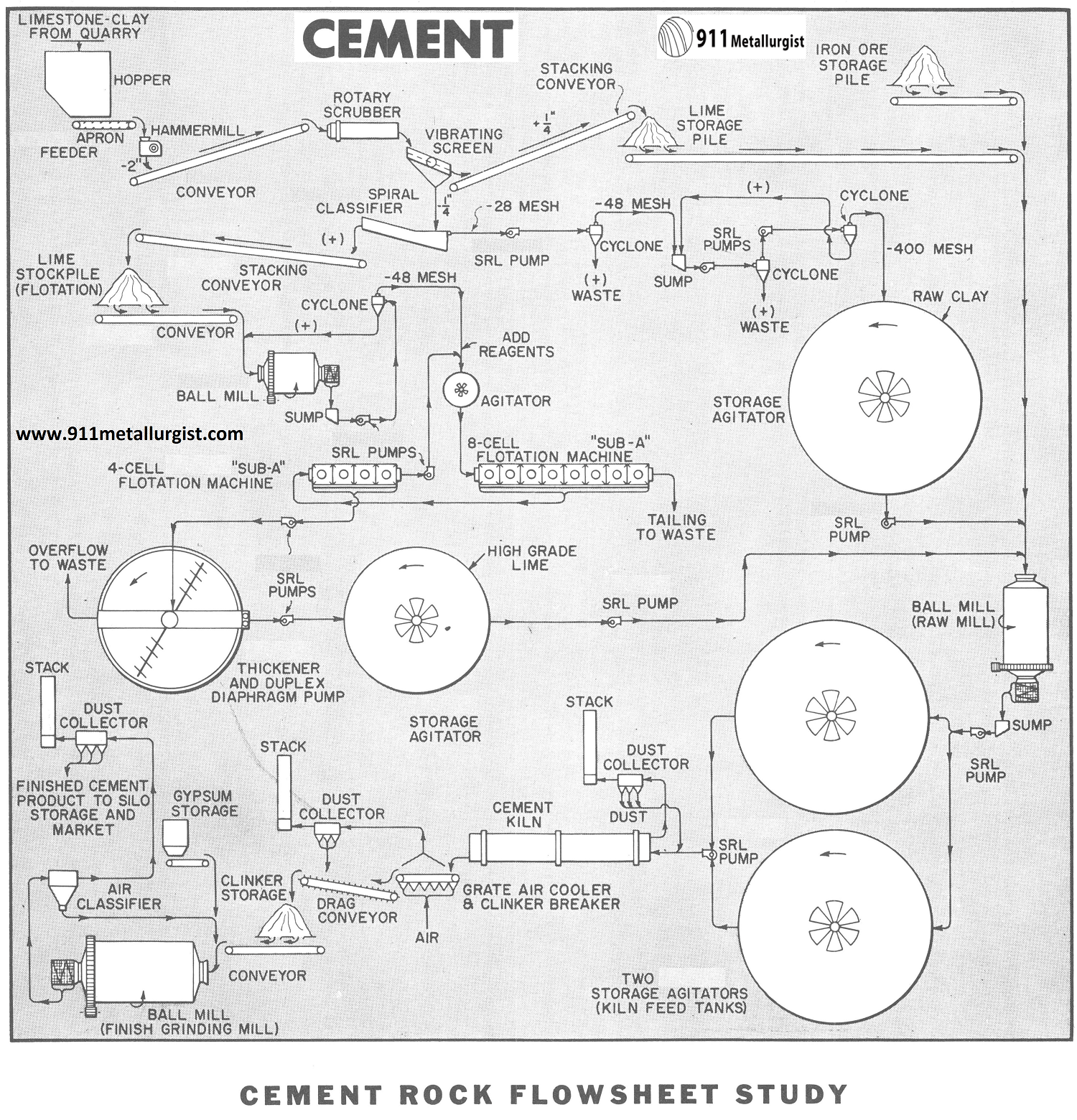

Cement Rock Beneficiation Process

The below Cement Rock Beneficiation Process flowsheet represents a simplified flow diagram of a cement plant in which beneficiation of raw materials is employed. Using a crude feed of limestone and/or clay, the flowsheet produces raw clay by multi-stage cycloning, and “Sub-A” Flotation upgrades the impure limestone. Turbine-type Agitators are used for storage and homogenous mixing […]

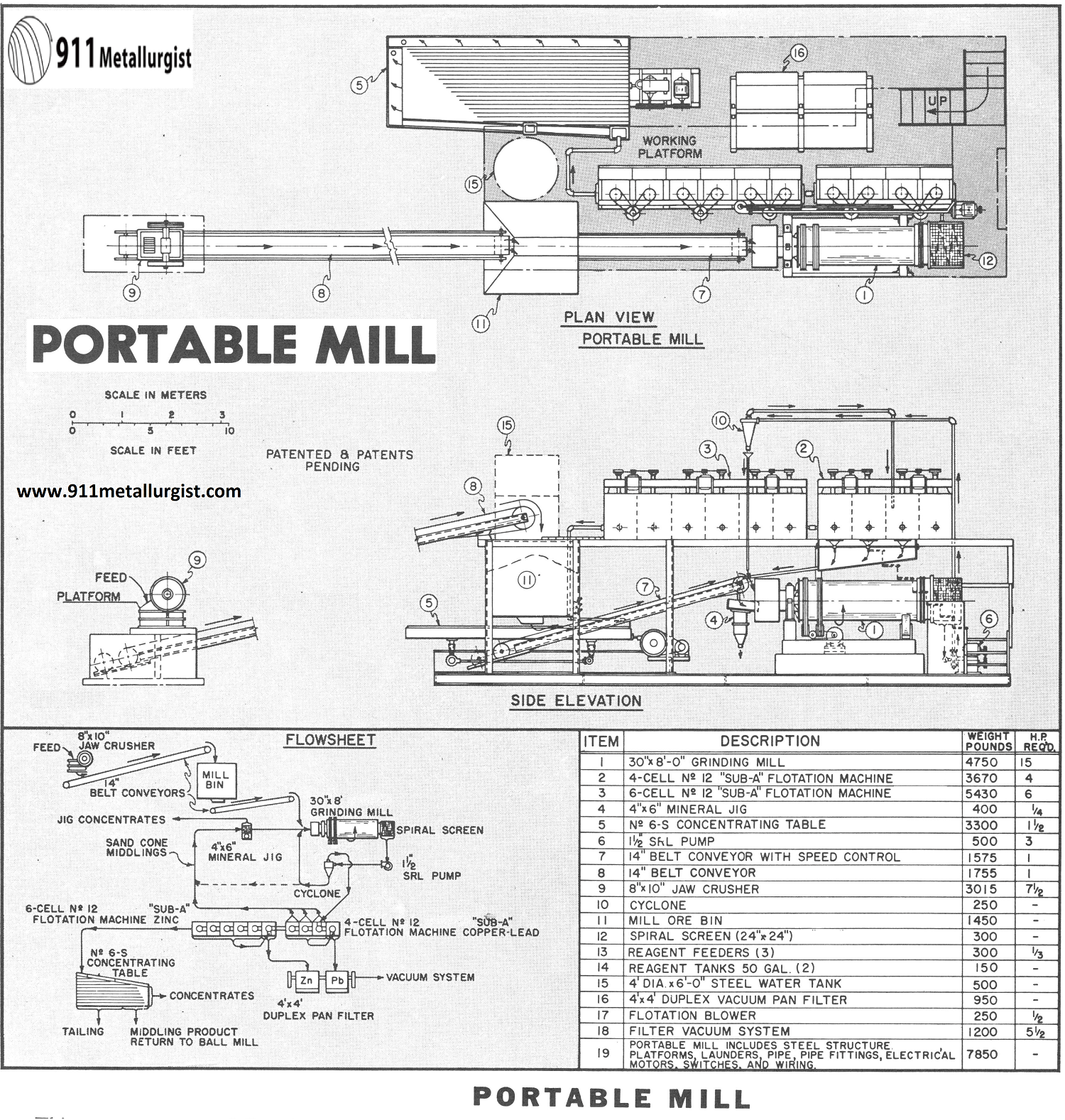

Small Portable Gold Process Plant

This arrangement and flowsheet of a Mini Portable Gold Processing Plant permits several mineral separations by flotation and provides for the possible recovery of other minerals by gravity concentration. The flowsheet is ideal for a pilot-plant in field testing of ores to determine the economic feasibility of an ore deposit prior to the installation of […]

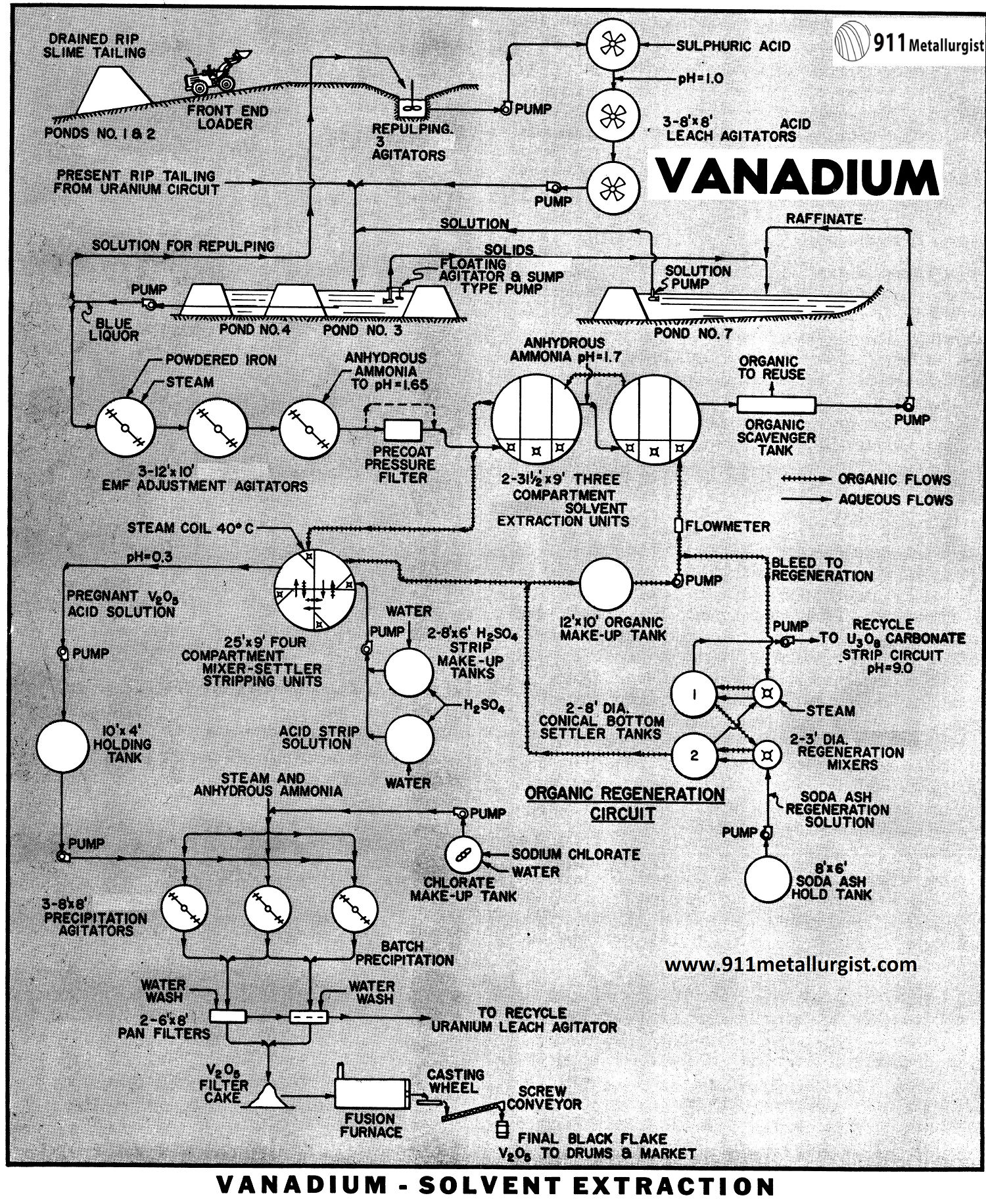

Vanadium Extraction Process

The extraction and recovery process of vanadium as a by-product from the tailings of a uranium processing plant poses many problems. In this study vanadium is recovered from impounded resin-in-pulp tailings and from the current tailings of a uranium plant which did not include a circuit for vanadium recovery in its initial design. Since the vanadium content is quite low, […]

Tin Ore Extraction

The flowsheet below Explains the Extraction of Tin Ore as shown by a study adapted to the concentration of a lode tin deposit. Cassiterite (SnO2) is very friable and special considerations to crushing and grinding of the ore are necessary to avoid an excessive production of fines. The Mineral Jig is an important feature of […]