Copper Ore Extraction

Aerial view of the Opemiska Copper Mines (Quebec) Ltd., Mill Buildings and Shaft Area. Introduction The Opemiska mine property is in Levy Township in Chibougamau area of Quebec and is comprised of 487 acres of patented claims contiguous with 2,215 acres held under development license. The townsite of Chapais which serves the mine community is […]

Complex Base Metal Process Plant Circuit

The flowsheet in this study was designed to treat 500 tons per day of a complex base metal ore containing gold and silver values. The presence of free gold offers opportunity to recover these values in the grinding circuit so that the gold could be amalgamated, and marketed directly to the U.S. mint. The ore […]

Poly-metallic Process Plant Design

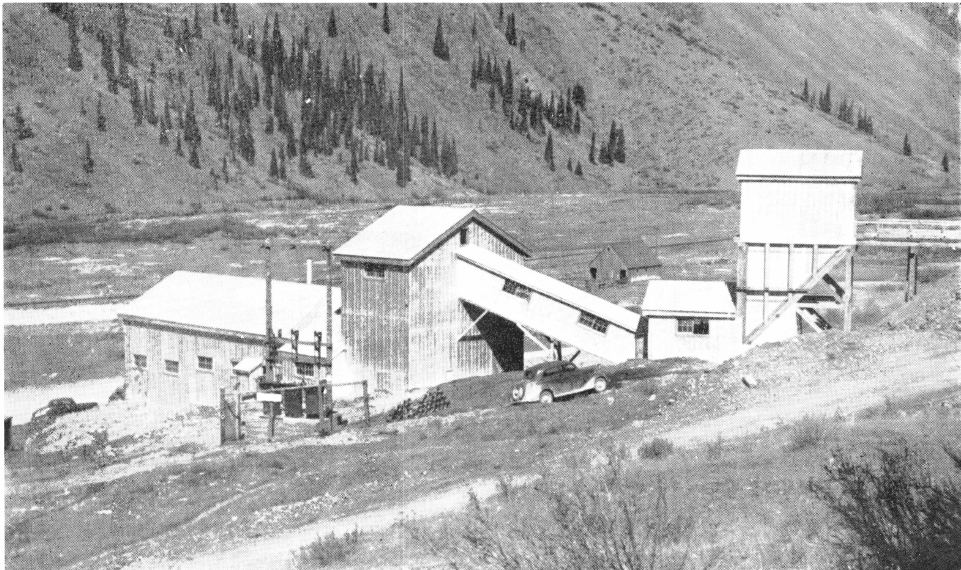

The San Juan Mountains of Western Colorado are often referred to as the “Switzerland of America.” Among the many mining properties in this area is the well-known Camp Bird mine. The history of this property dates to 1877 although its really active beginning was on May 12, 1902 when Camp Bird Limited, an English company, […]

How to Separate Ferrous & Non Ferrous Metals Scraps

Scrap metal, both ferrous and non-ferrous, present in industrial wastes, slags, smelter bi-products, sludges, refinery sweepings, ashes, etc., can be reclaimed in most instances at a profit and thus are made available for reuse in industry. Very substantial stockpiles of these scrap metal wastes are available for processing in the various industrial areas. 911metallurgist.com through […]

Counter Current Decantation Design Formula

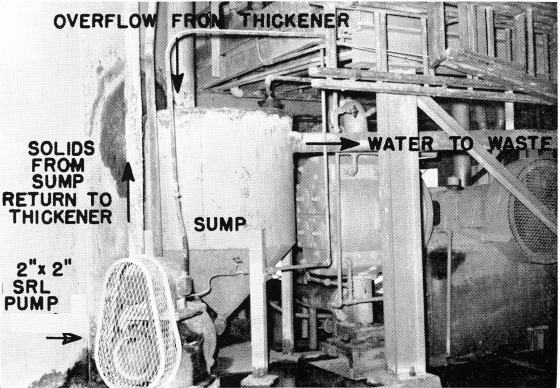

The principle of Counter Current Decantation is simply that, when water or solution is to act upon solids, both are made to pass, in contact, in opposite directions, so that at each end the strongest or most potent portion of either is acting upon the weakest or most exhausted portion of the other. The recovery […]

Sink and Float Separation Process

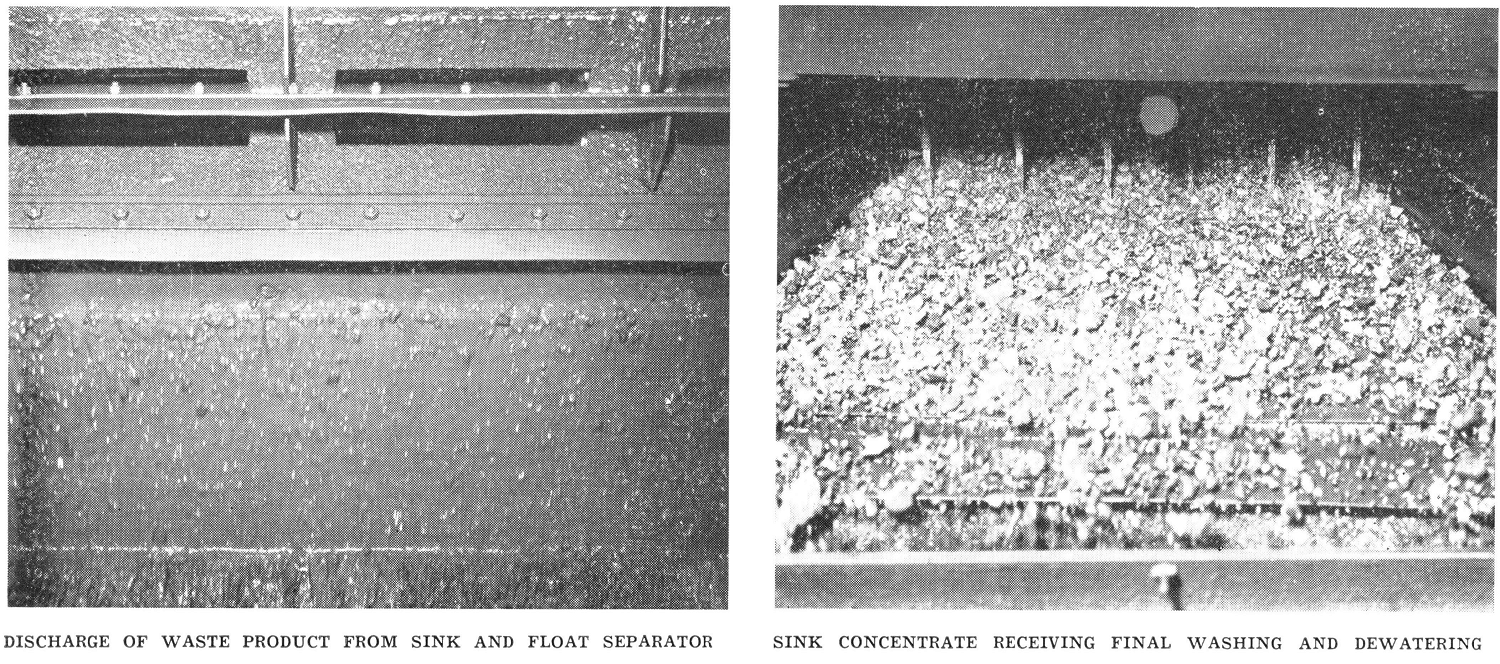

The Sink and Float Separation Process is an alternative to the progressive depletion, during the last quarter century, of ores which could be economically treated by the old methods of gravity concentration necessitated the development of more efficient methods of concentration, the most successful and widely used of these methods being the Flotation Process. But […]

Gold Leaching

Gold Leaching Process Circuit NO. CY-1 This leach plant shows the continuous counter-current decantation system, in which all the ore is first reduced to a very fine state in the grinding mill-classifier circuit, in a Gold Leaching solution. The slime overflow of the classifier, usually 70%—200 mesh, or finer, is sent to the first thickener, known […]

Froth Flotation Principles

The Froth Flotation Machine is universally used for all types of flotation problems. This machine finds a wide acceptance due to its flexibility in construction, which allows the machine to be adjusted to handle pulps with divergent physical characteristics, as well as the common and intricate metallurgical problems which confront the present day operator. The Froth […]

Mineral Processing Plant Design & Construction Example

Metallurgical Recovery, which consists of the percentage of mineral saved, must not be confused with economic recovery which covers the percentage of the gross value of an ore recovered as a net profit. In other words, in commercial practice the prime object is the highest possible net profit over and above all costs. Thus a […]

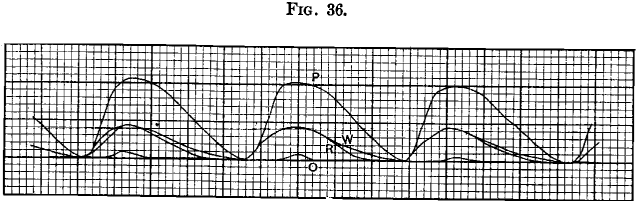

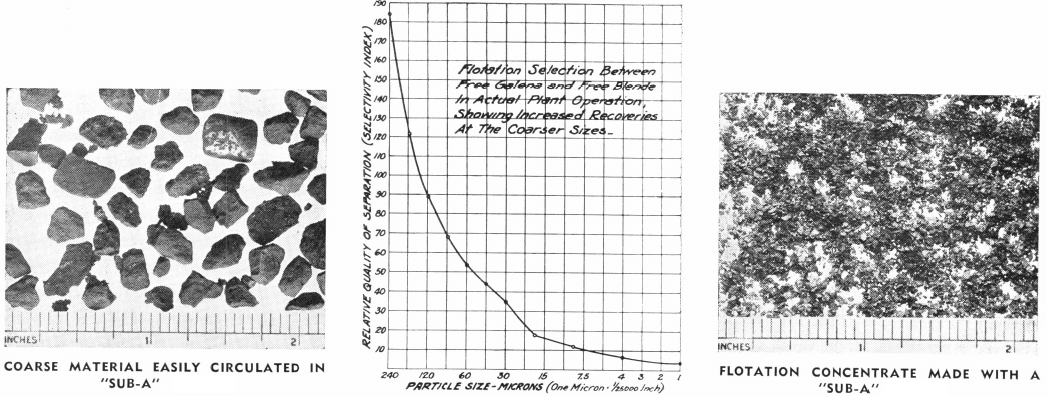

Coarse and Fine Particle Flotation Recovery

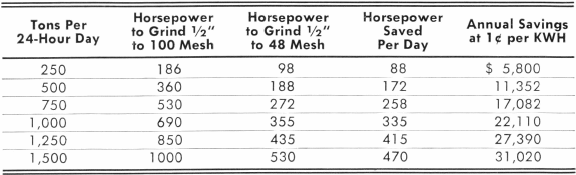

In The Days of gravity concentration, the art of ore dressing developed on the cardinal principle of saving the values at as coarse a size as possible. Flowsheets were designed which featured an alternation of crushing and concentrating operations. Thus an ore might be crushed to ½ inch, jigged to yield a finished concentrate and a […]