Potassium Salt Flotation from Salt Lake Evaporites

The U.S. Bureau of Mines and Great Salt Lake Minerals and Chemical Corp. developed a froth flotation process for concentrating potassium salts from Great Salt Lake solar evaporites containing about 5 percent K. The crude evaporites, which were predominately halite (NaCl) with smaller amounts of kainite (KCl·MgSO4·2·7H2O) and schoenite (K2SO4MgSO4·6H2O), were conditioned in a saturated […]

Dynamic Effects in Bubble Particle Collision

Rendering a solid hydrophobic and solid-fluid particle attachment in flotation are recognized is not necessarily related. The attachment is governed by forces of attraction and repulsion which need to be considered. The induction time required for attachment after solid and fluid particle are brought into proximity illustrates the point. Thinning and Rupture of the Disjoining […]

Sulphidized Cassiterite & Iron Oxides Separation

Low recoveries of cassiterite are obtained by gravity concentration of lode deposits, particularly if the cassiterite calls for fine grinding of the ore. And it is precisely this finely ground ore that is the cause of the low recoveries. The possibility therefore of upgrading the ore by flotation has been of great interest to the […]

Predicting Flotation Recovery

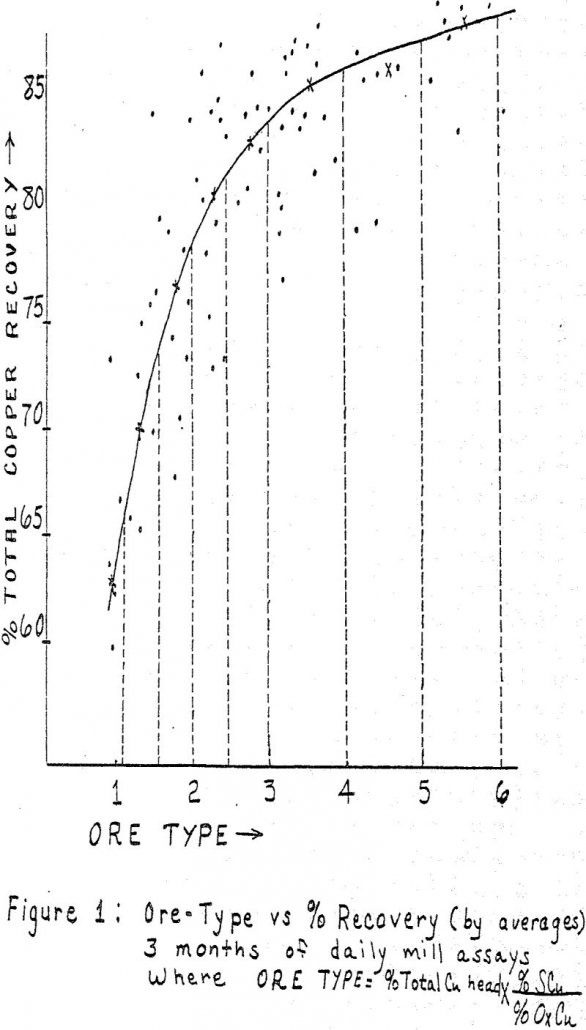

Unfortunately, many milling engineers rely rather heavily on percent recovery as a strict measure of a concentrator’s relative performance. The fallacy of this reasoning is not difficult to see since, by definition, percent recovery is a function of feed assay, tails, and concentrate grade. If copper tailing is constant, and it very nearly is for […]

Molybdenite Flotation Operating Variables

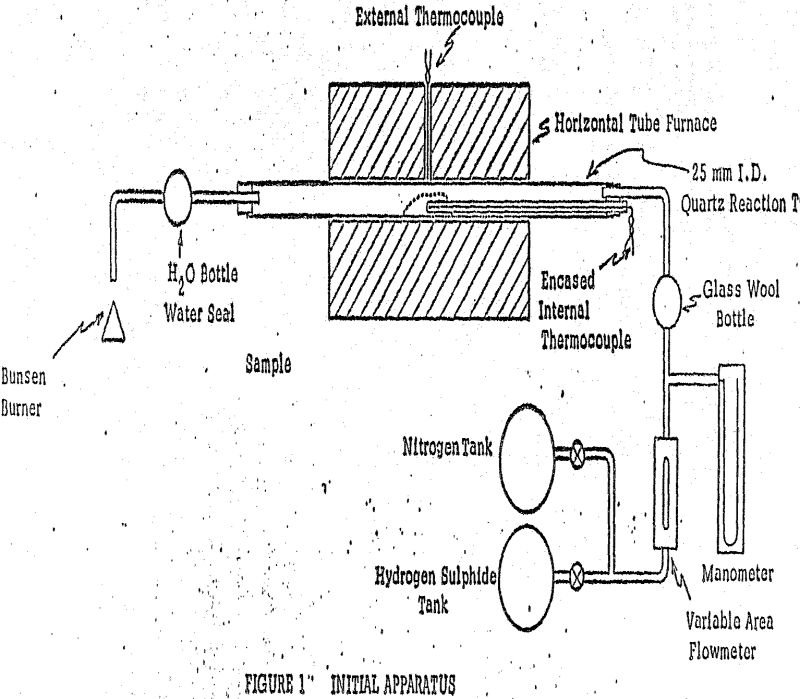

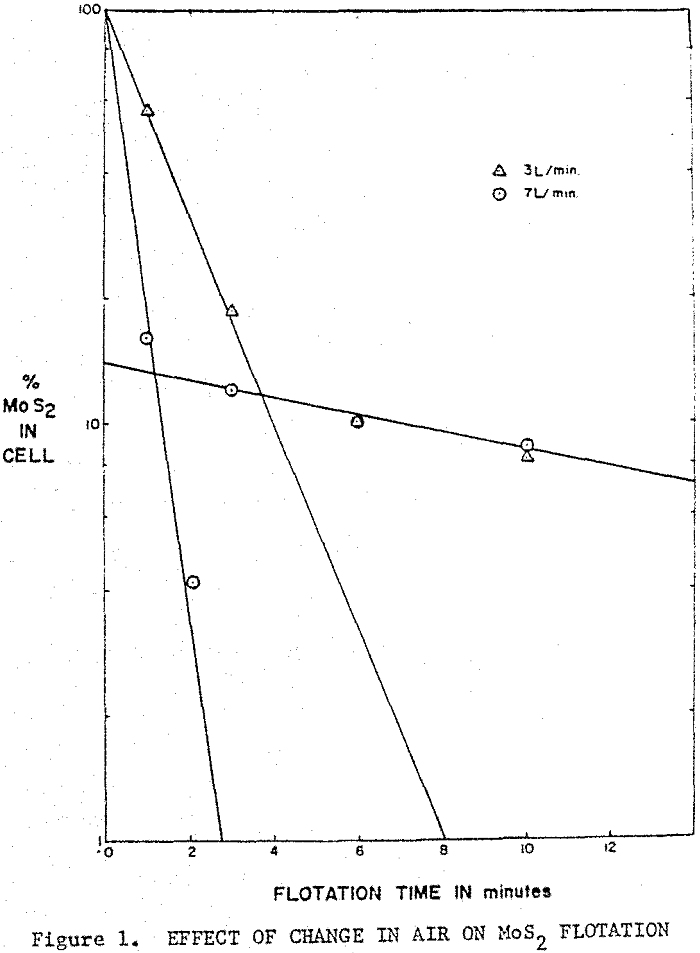

The number of variables which can effect flotation of molybdenite is very large. The analysis of flotation results indicate that molybdenite can be characterized into fast-floating and slow-floating components. The rates of fast-floating components, which do not create a problem in flotation, could be varied by changing agitation of airflow rates. Experimental For the laboratory […]

Open Circuit Flotation

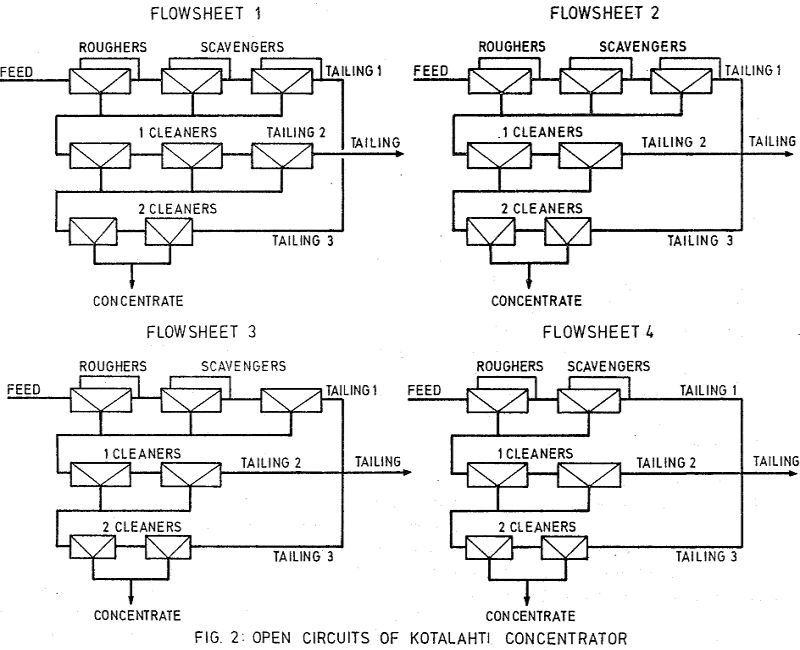

The use of open circuit flotation is common practice in porphyry copper ore concentrators and Australian copper concentrators and its use in other than copper concentrators is minimal a completely open flotation circuit is not used and it is general practice to have recirculation within the cleaner flotation stage. The Kotalahti Concentrator. The recovered minerals are […]

Copper Lead Separation with Activated Carbon

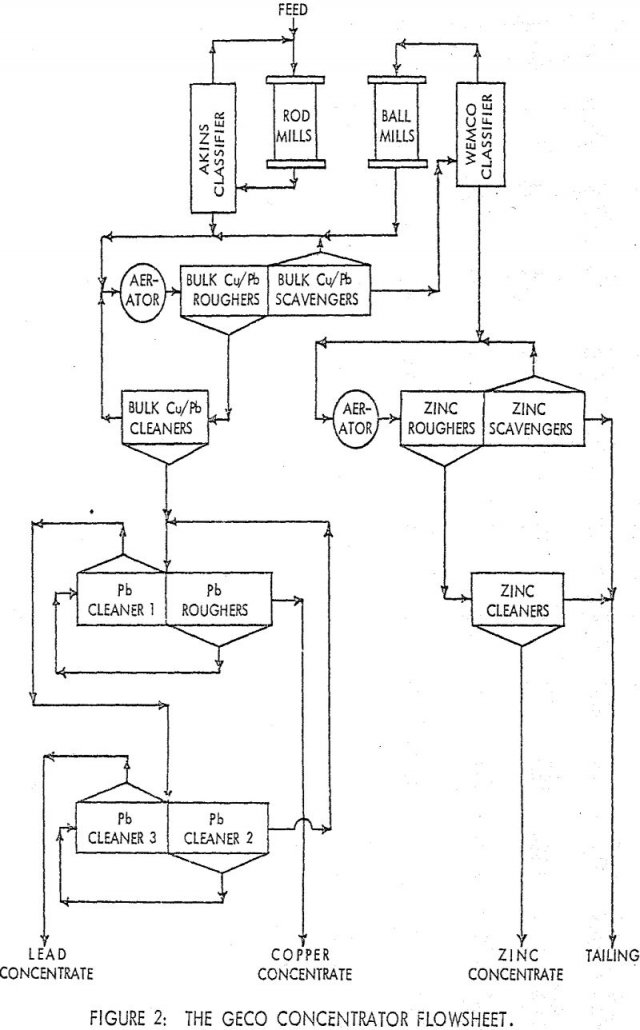

In many multiple-sulphide ore flotation processes, it is desirable to concentrate each of the various valuable minerals into separate products. Although there are a variety of techniques and chemicals which can be employed to produce efficient separation, two basic types of flotation circuits are used: The Differential Flotation Circuit and the Bulk/Selective Flotation Circuit. Geco […]

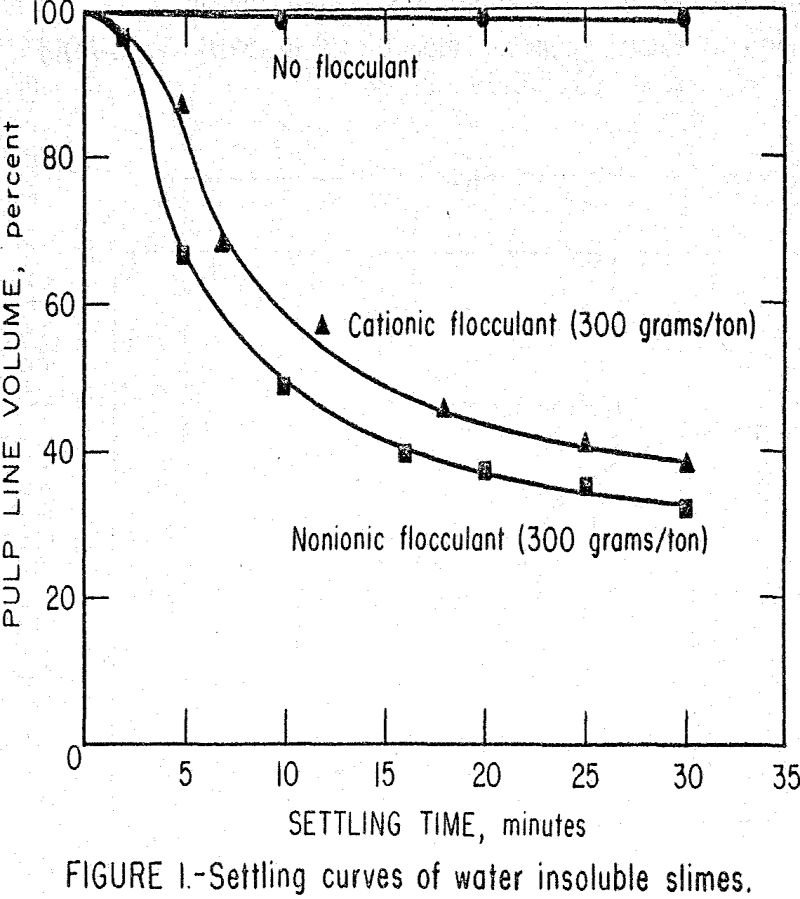

Flotation of Insoluble Slimes from Potash Ore

Filtration of the insoluble slimes flotation concentrates recovered 87 to 90 percent of the brine. Flotation concentrate filtration rates were 7 times faster than the filtration rates of mechanically deslimed products. Potash losses in the deslime product and process brine requirements increase as the insol content increases. Therefore, improved methods to remove inso lslimes are […]

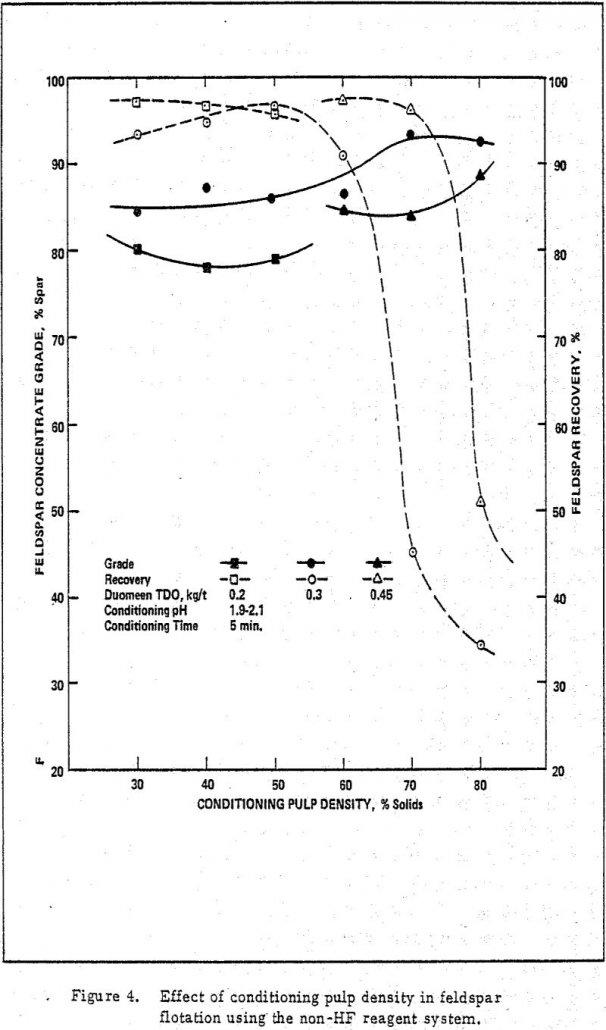

Feldspar Flotation using Non-Hydrofluoric Acid System

The response of feldspar flotation to tallow diamine dioleate collector in the presence of sulfuric acid is studied using, batch flotation experiments. Application of this non- hydrofluoric acid (non-HF) reagent system in the flotation of mineralogically and chemically different feldspar ores is compared with that of the conventional hydrofluoric acid system. The dependence of flotation […]

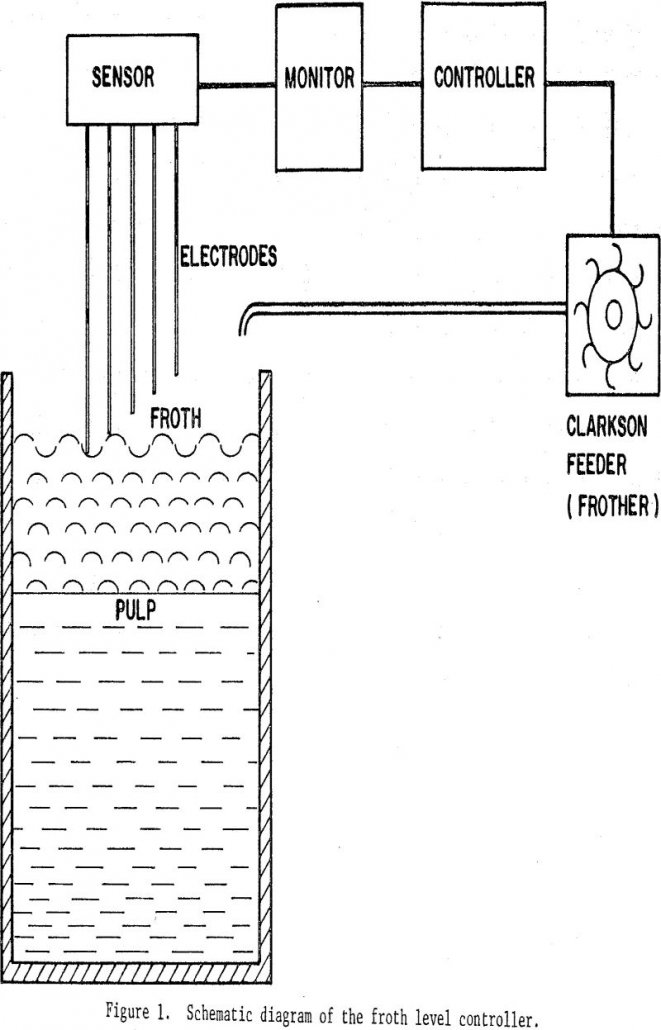

Froth Level & Pulp Density Control

The possibility of increasing the efficiency of mineral processing plants by means of computer control has prompted metallurgists to examine their flowsheets more critically in order to develop practical control strategies. Control schemes in use to date generally rely on the automation of traditional and previously manually regulated control loops, for instance the addition of […]