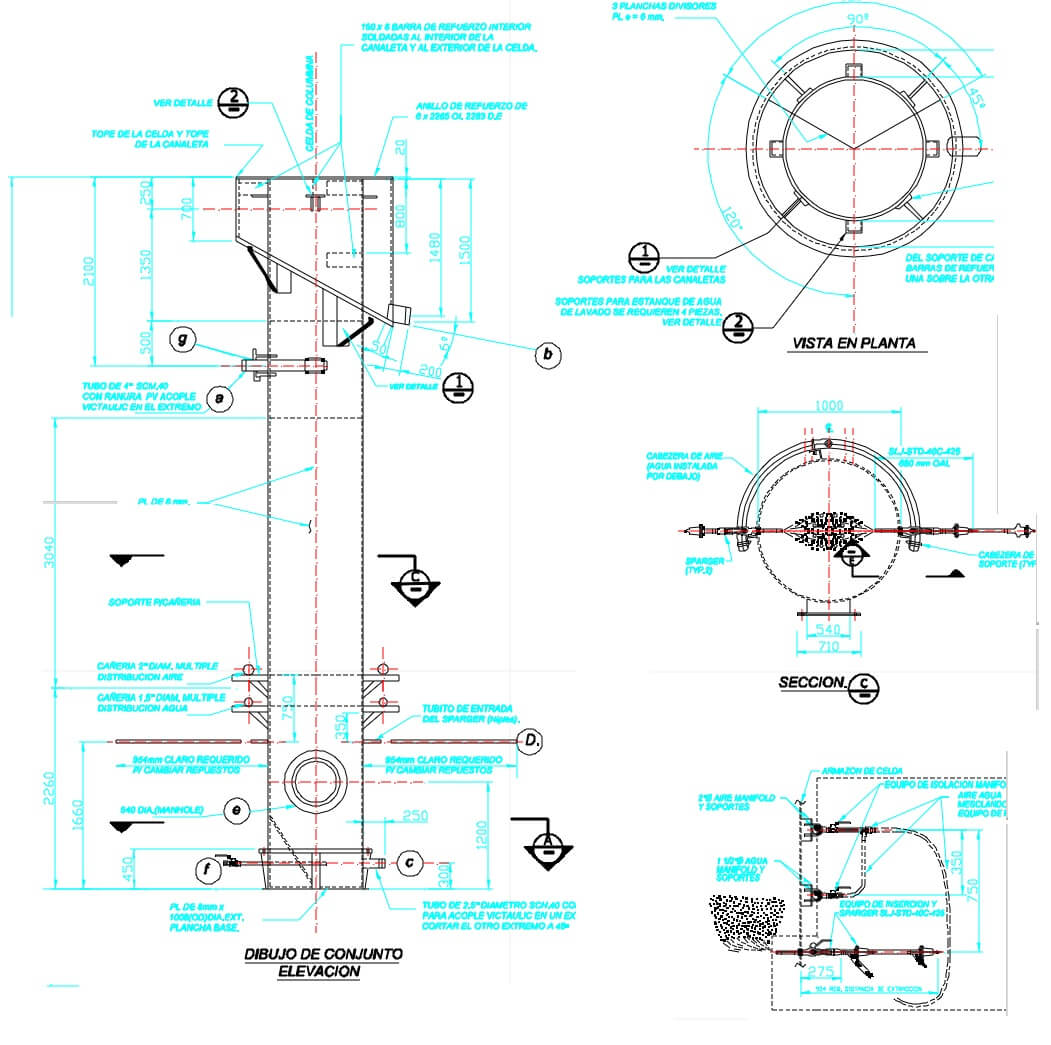

Flotation Column Design

Here is a classic Flotation Column Design with air spargers, froth launders and wash water header/tub. Column Flotation Cells make great “grade machines” but are know as weak on recovery. Low energy, low recoveries at each end of the size particle spectrum.

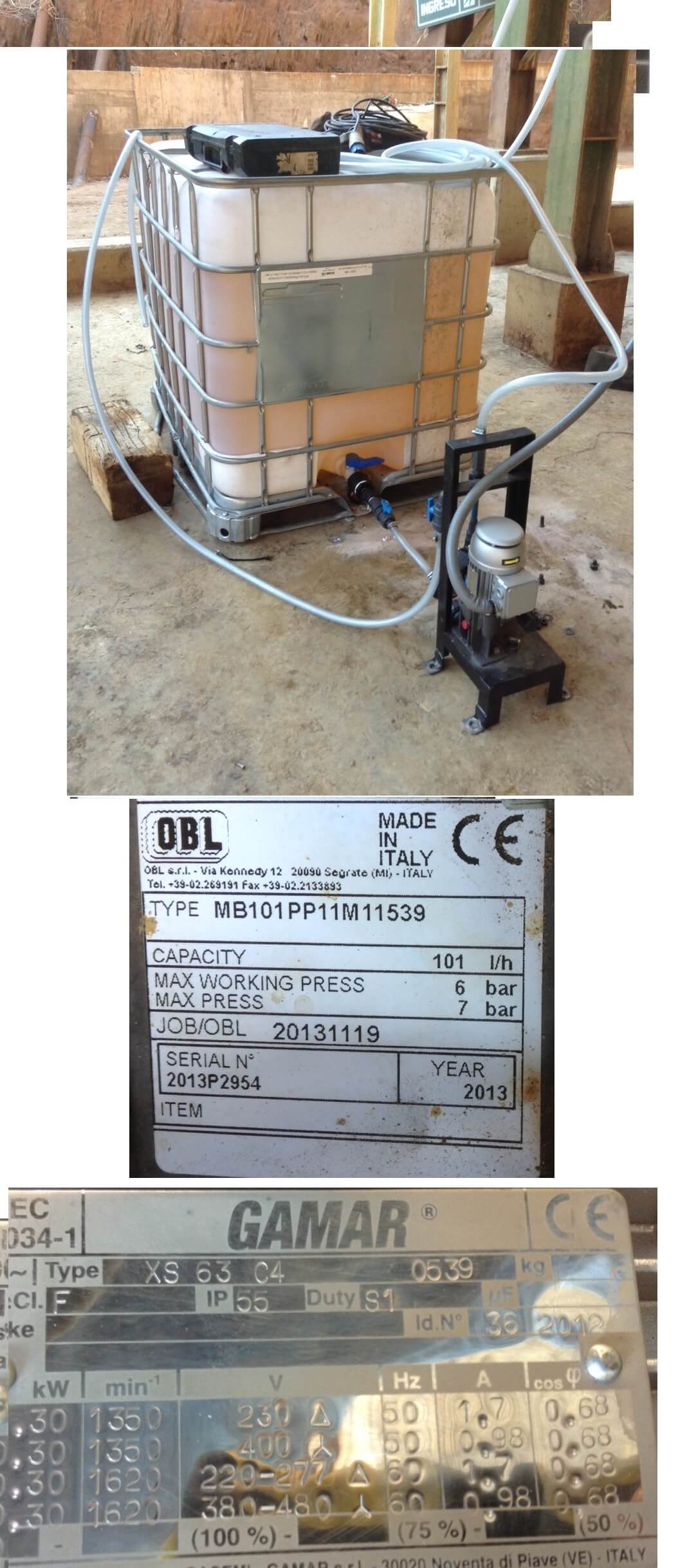

Flotation Reagent Metering Pumps

I recently did a reagent plant trial and worked with a pretty nice flotation reagent metering pumps. The pump is supplied by https://www.pmps.co.za This portable reagent supply unit is a mechanical diaphragm metering pump. As see on https://www.pmps.co.za/obl-mechanical-diaphragm-dosing-pump They even had “Water Driven Pumps” Other pumps I never worked with include https://www.awe-ltd.co.uk/products/dosing_pumps_electronic.html and https://www.lutzjescoamerica.com/index.php?id=1645 Also https://www.911metallurgist.com/mibc-frother-pump

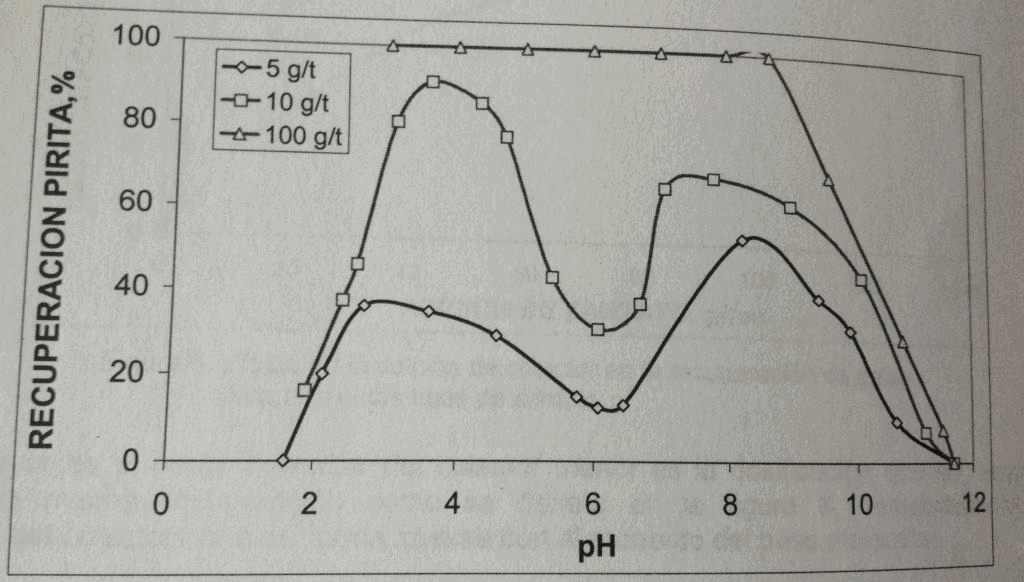

Sodium Metabisulfite MBS for pH Control and Pyrite Depression in Flotation

Sodium Metabisulfite aka MBS is used for pH control in froth flotation to control Pyrite depression. Below is a graph showing pH VS pyrite recovery at various collector addition rates. It is also used to prevent flotation of sphalerite by copper activation in the presence of Tennantite/Covellite in the ore. For pyrite flotation, you see maximum iron/pyrite […]

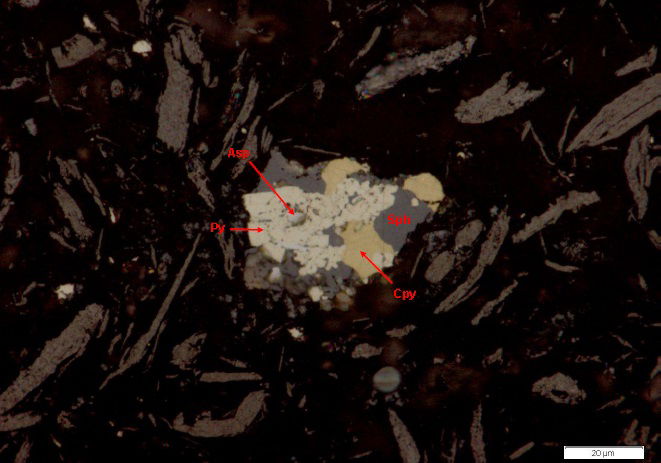

Disseminated Ore Deposits | Complex Polymetallic Mineralogy

You do not know what Disseminated Polymetallic Ore Deposits or Complex Mineralogy until you have seen a QEMSCAN like this: With simple main observations as crazy as these below. ***The proportion of each mineral liberated at a 56µm grind P80 was: Chalcopyrite — 36% liberated Galena — 12% liberated Sphalerite — 45% liberated Pyrite — 85% liberated […]

Quick Grind Check -How to Quickly Estimate Grind Size or P80 | Operator Tips

An easy and fast/quick way for grinding operators to get an idea and estimate their grinds is to follow this procedure. https://www.metcomconsulting.com/ Using a calculator an those 2 simple tools will get you a fast P80 or Pxyz. This great simple tool/method lets you estimate the grind size of any stream using a wet vibrating […]

Optimum Froth Bed Depth Levels

When the pulp levels on all cells appears high (shallow froth bed thicknesses or depth). This causes unstable froth which constantly produces a low density “run-away” or wet, watery un-drained rougher concentrate rich in mechanically floated (entrained) “other materials” and containing most of the frother (added to flotation feed) itself. ** Operating at shallow froth […]

Compare Hydroxamate AM2 Rinkalore CTC3 Oxide Collectors

In this series of tests aimed to Compare Hydroxamate Collectors namely: AM2 Rinkalore and CTC3 we now conclude. All data indicate the CTC3 is a more selective reagent. In all tests, metallurgy was improved. Nowhere were the results produced by CTC3 inferior to AM2. Although AM2’s Lab Recoveries can look “attractive”, the AM2 reagent shows problematic […]

Hydroxamate for Copper Oxide Flotation

Here is a comparison of two Hydroxamate Collectors used for the flotation of Oxide copper, namely CTC3 from OXFLO and AM2 (AKA Rinkalore) from AXISHOUSE. This report contains a comparison of the scoping test-work done by both suppliers to determine which one is the best Oxide Collector . Test Summary #1 Flotation by Hydroxamate: OXFLO’ […]

The Importance of %Mass Pull in a Flotation Circuit | What is Flotation Mass Pull

What is flotation mass pull and why does it matter so much? If we consider the total Plant Feed of 2800 TPD as 100% of the mass and we produce say 59% Cu Recovery or 84 TPD of Cu conc, we would find that 3% of the “mass” is in the concentrate. We therefore label […]