Effect pH on Moly Rougher Recovery by Flotation

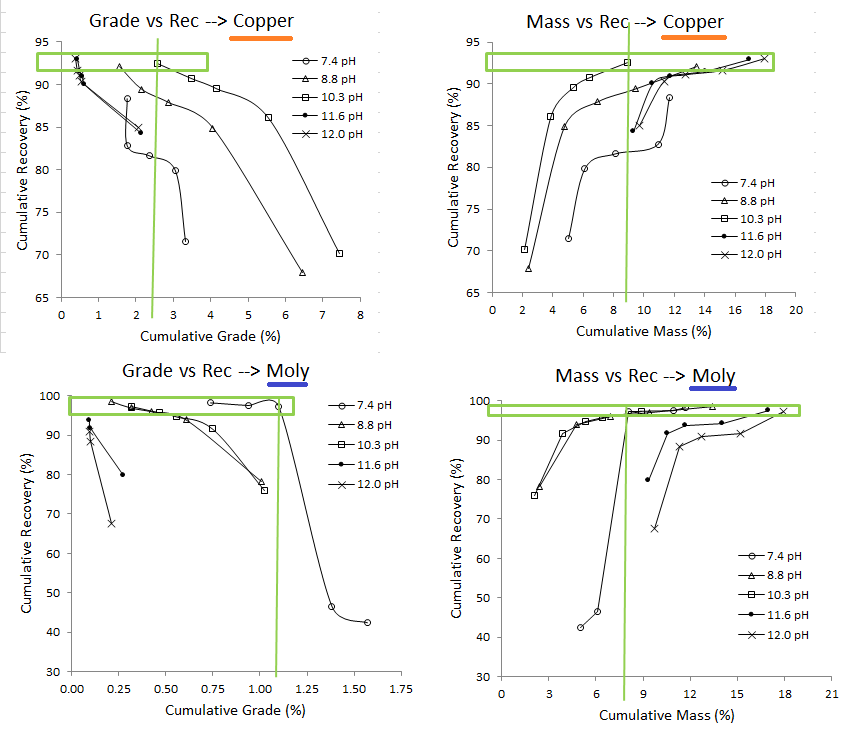

pH was varied in the moly flotation in roughers while attempting to maintain a eH in the low -500 mV. The results of the test, shows that the best recoveries of moly are achieved at pH values of 9 and below. The copper recoveries appear to get activated at these low pH values, but the […]

Effect of pH on Bulk Flotation of Copper – Molybdenum

Graphic Conclusions of this particular set of flotation tests: Copper – Irrelevant of pH, with enough float time and reagents, you usually reach a terminal bulk rougher Cu recovery in the low 90s (Green Box) – pH 10.3 gives you that terminal recovery in less mass (9%), more selectively, at a higher Conc grade (2.5%) […]

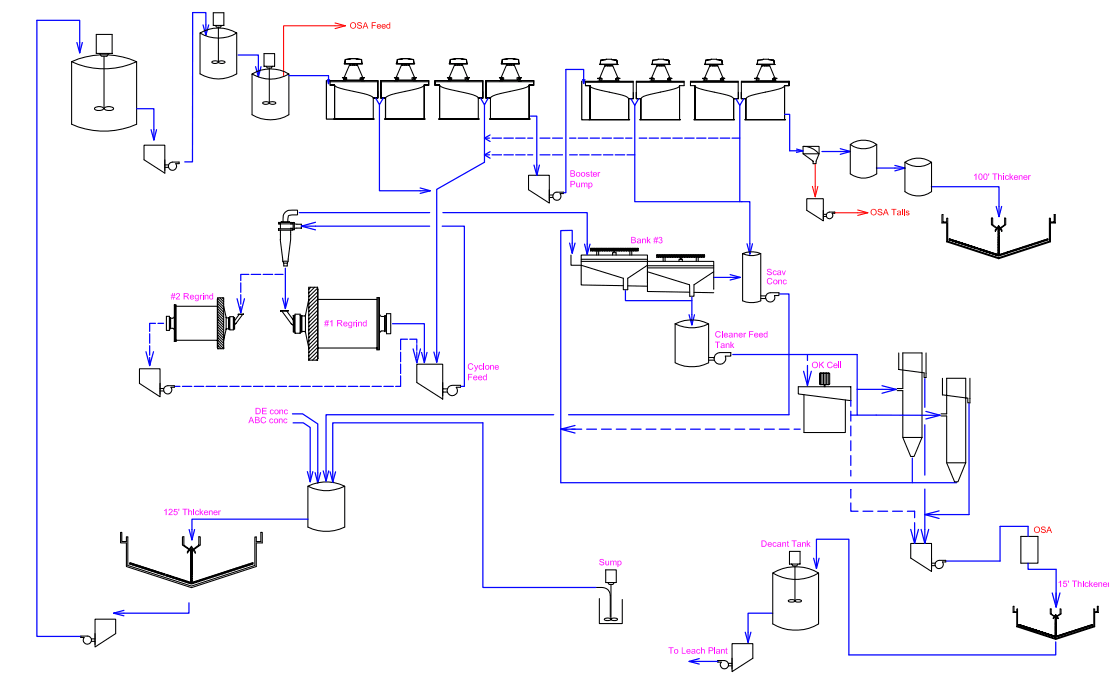

Proven Cu Mo Separation Circuit Flowsheet

Here is a Proven Cu Mo Separation Circuit Flowsheet (by flotation) many will model after. It is used a Canada’s largest copper-molybdenum mine. It uses NaSH and Nitrogen.

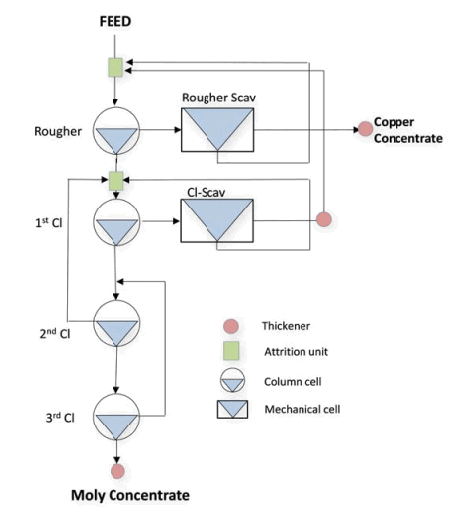

Model Example of Copper-Moly Separation Circuit and Flowsheet

The copper-moly separation circuit was modelled using the test kinetics. The circuit was configured to include columns in every stage in order to minimize the amount of entrainment and to maximize the washing effect of the molybdenum concentrate. The circuit was designed with long retention times so that it could be operated with a slow […]

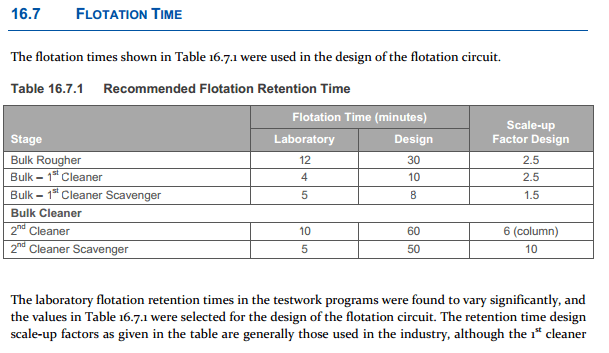

Flotation Time Scale-up Factors – Laboratory to Plant

Using Laboratory bench-top float test results and their retention (flotation) time to scale-up to real life full scale plant time can be done using the following tables and examples. How to select the proper scale-up factor takes experience and …. good data. Figure 16.7 was used and seen in the a technical report for the Pebble […]

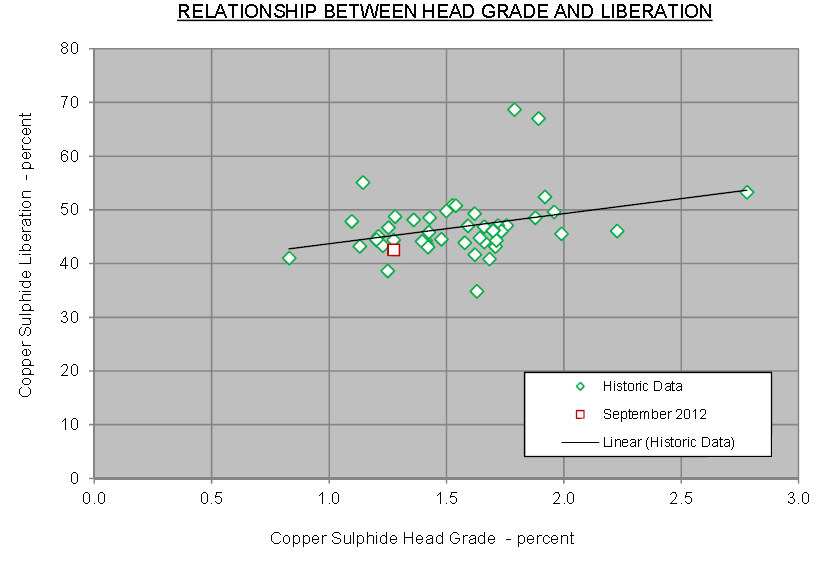

What is the Relationship between Head Grade and Mineral Liberation

Some plant operators claim their metallurgical recovery targets are harder, more difficult, to meet as head grades drops down. Is it true or is it just voodoo? Using Mineralogy can answer this question scientifically. Relationship between Head Grade and Mineral Liberation EXAMPLE The red/white dot points to the actual monthly liberation of 42% VS history. […]

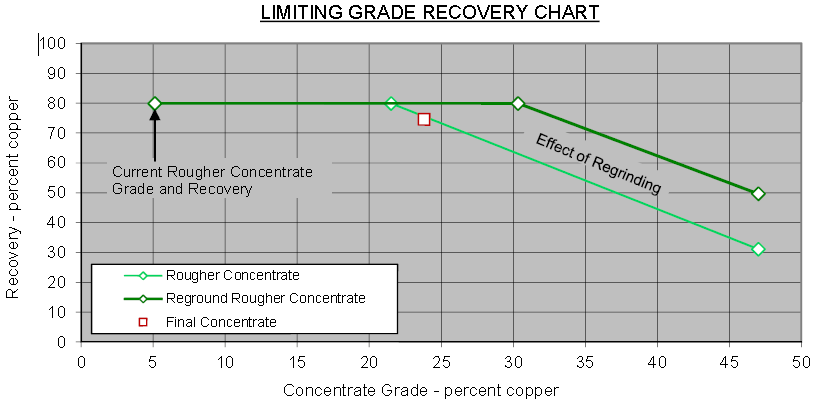

Effect of Regrind on Grade and Recovery

How do you know if or when regrinding and applying further liberation power can improve your metal’s recovery? Below here is data showing what is to be gained by correctly applying regrind to a copper stream. On the graph, the red/white dot points to where the plan currently is light green Grade-Recovery curve VS where is could be on […]

High Tech Flotation Reagent Addition System

Evaluate Oxide Copper Recovery by Flotation

If the idea is try to recover, by flotation, copper oxides that are located in the upper part of the deposit. According to geology department the main copper oxide minerals are chrysocolla and atacamite. There are small quantities of azurite and malachite. As far as I know, it is difficult to float chrysocolla. Malachite and […]

Flotation of Marmatite

The chemical formula for sphalerite and marmatite is (Zn,Fe)S not (ZnFeS2). The iron and solid solution are in a solid solution and marmatite (there is technically no mineral called marmatite) is referred to as the high iron variety of sphalerite https://en.wiktionary.org/wiki/marmatite They have the same flotation properties and the high iron content makes the sphalerite […]