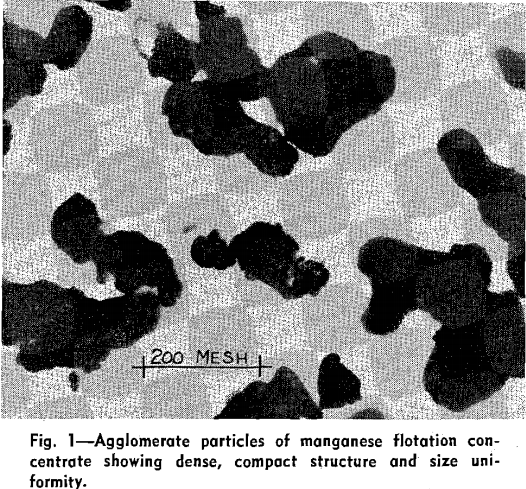

Agglomeration Flotation of Manganese Ore

Beneficiation of the manganese oxide ores at Three Kids Mine near Henderson, Nev., has evolved over a period of years. Commercial application of the process is on a secure basis, and an effective working hypothesis has been formulated to help solve the problems encountered in flotation. Ore Characteristics: Manganeses in the Three Kids ore occurs […]

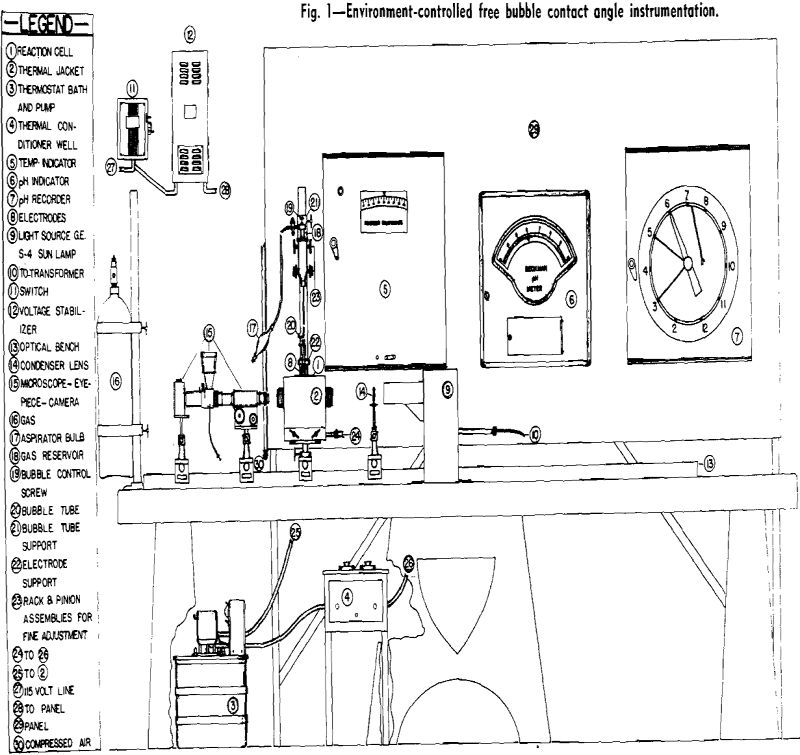

Flotation Contact Angle

In the use of free bubbles with precise temperature control and continuous pH measurement, the contact angle apparatus differs from all previous equipment. Experimental procedures differ sharply from the captive bubble method of introducing the gaseous phase in the three-phase system. When freed from the tube and captured by a solid surface, a bubble more […]

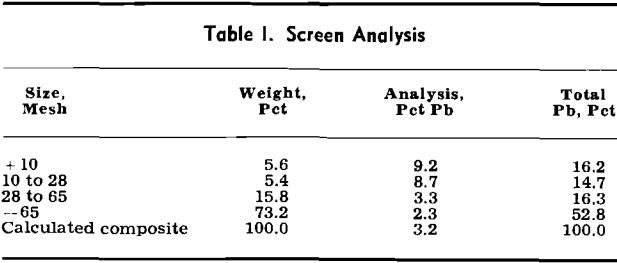

Laboratory Recovery of an Oxidized Lead Mineral

For several years work has been carried on by the U.S. Bureau of Mines at Rolla, Mo., to develop improved methods of concentrating the oxidized ores of lead and zinc. Various samples have been investigated, and results on some have been published. Preliminary Examination: The sample on which the following experimental work was conducted consisted […]

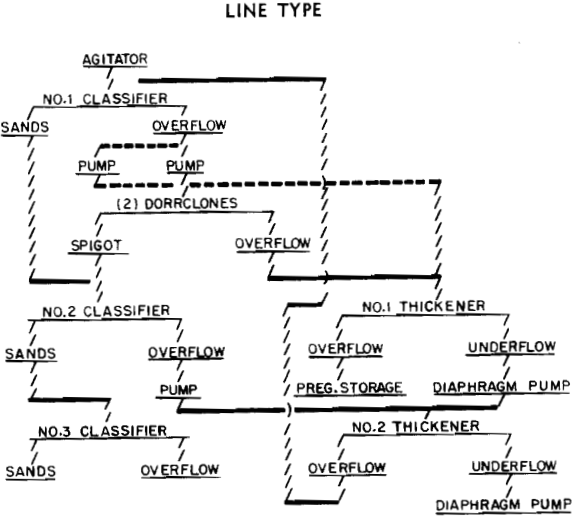

Flowsheets Types Uses

To those working in the mineral industry, the flowsheet is a familiar and valuable tool, seldom used, unfortunately, to its fullest advantage. As with so many other commonplace and simple items, there is little or no attempt to expand on the forms and types of flowsheets. A flowsheet or flow diagram may be defined as […]

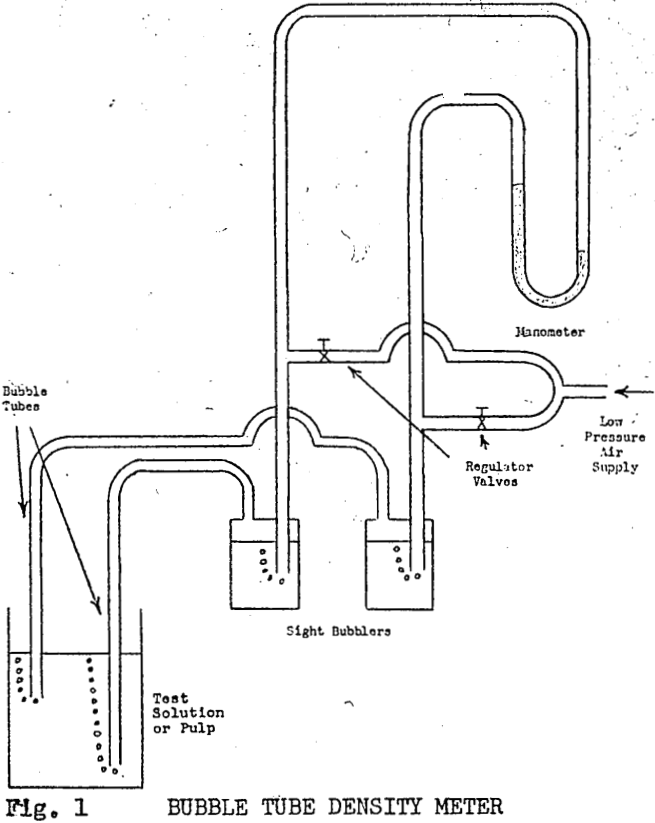

Pulp Density Measurement and Control

Measuring the specific gravity of a pulp in concentrating plants is a relatively simple procedure, but the desired accuracy is often difficult to attain. Many plants use the system of weighing a known volume of the pulp on a scale. In many cases, this method is quite accurate, but obtaining a true sample presents quite […]

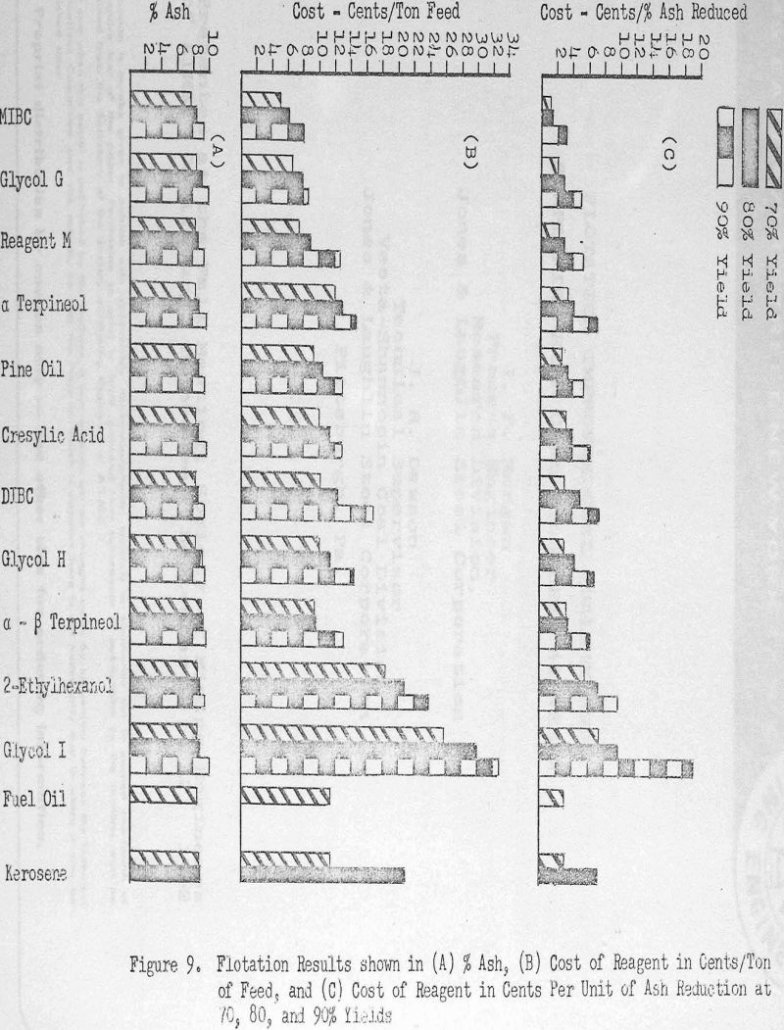

Coal Flotation Frothers – Yield Selectivity VS Cost

This paper presents the results of a study in which commercially available forms of various reagents were used as flotation frothers. Flotation procedures which would conform in general to those employed in a large number of commercial coal flotation plants were utilized. The reagents employed have been grouped into the following chemical classes; aliphatic alcohols […]

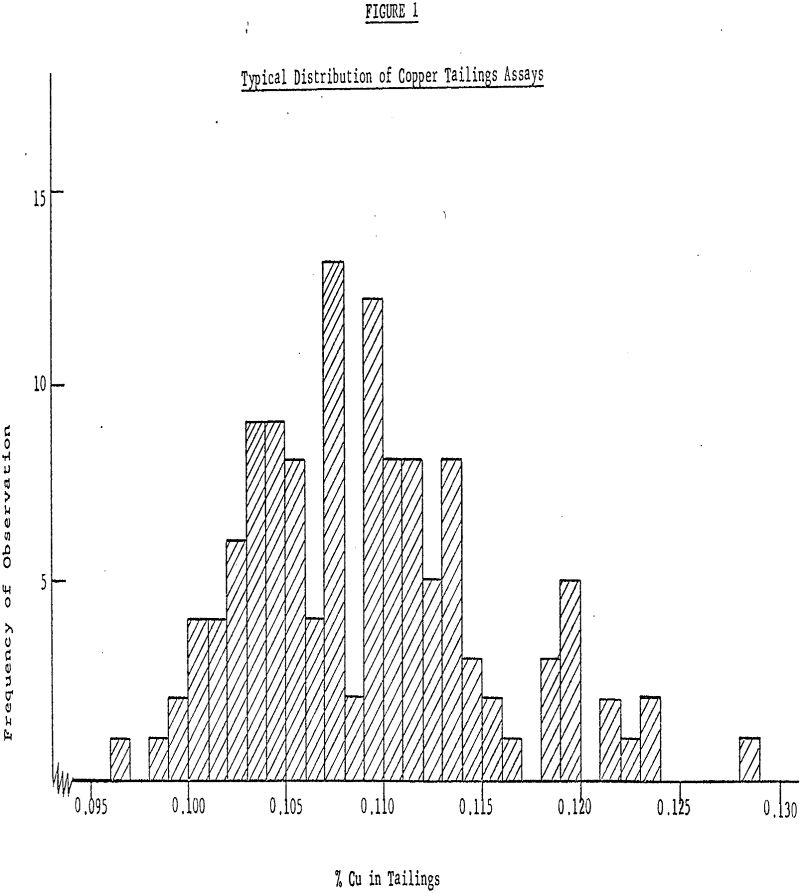

Reagent Testing – How to Analyse Results by Statistics

In the operation of today’s large scale ore-processing mills, it is extremely important to have some way of making an objective evaluation of the performance of the available flotation reagents. While Reagent Testing the use of Statistics is necessary for Result Analysis. Attempts to do this may often result in inconclusive findings since the magnitude […]

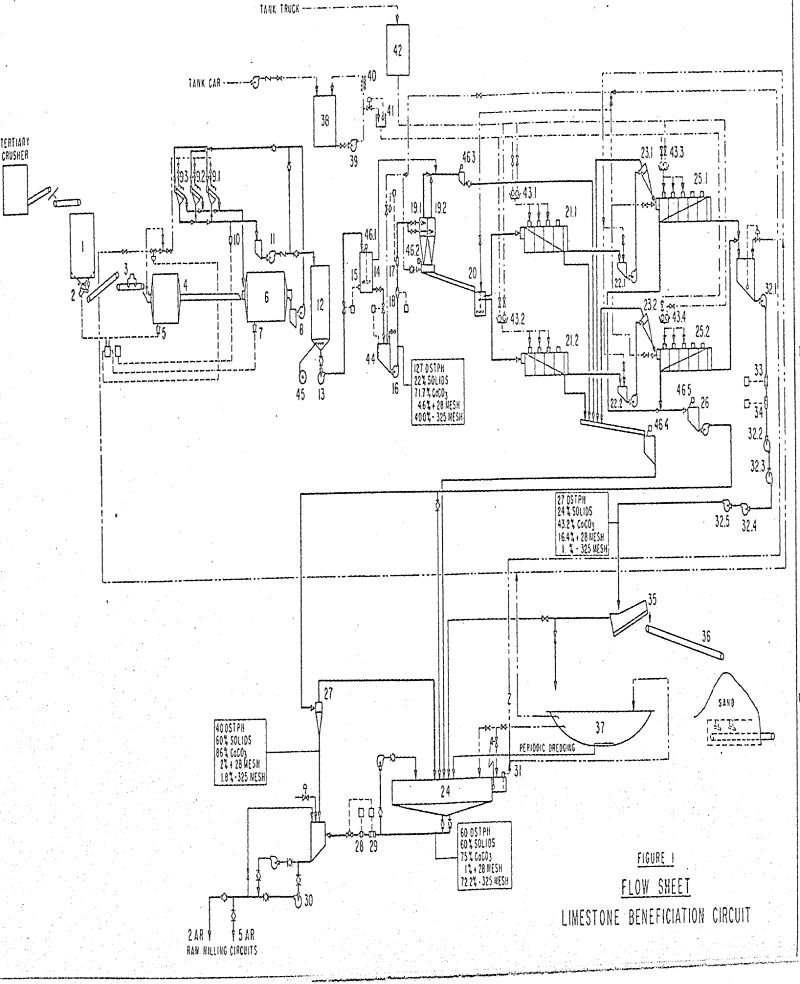

Limestone Flotation Circuit

From time to time since the initial installation of an experimental flotation section in 1940, Permanente Cement Company has made efforts to beneficiate the low-grade limestone fraction which occurs in its deposit at Permanente, California. Limestone and the Reason for Its Beneficiation The Permanente deposit is a sheet of Calera limestone over 700 feet thick […]

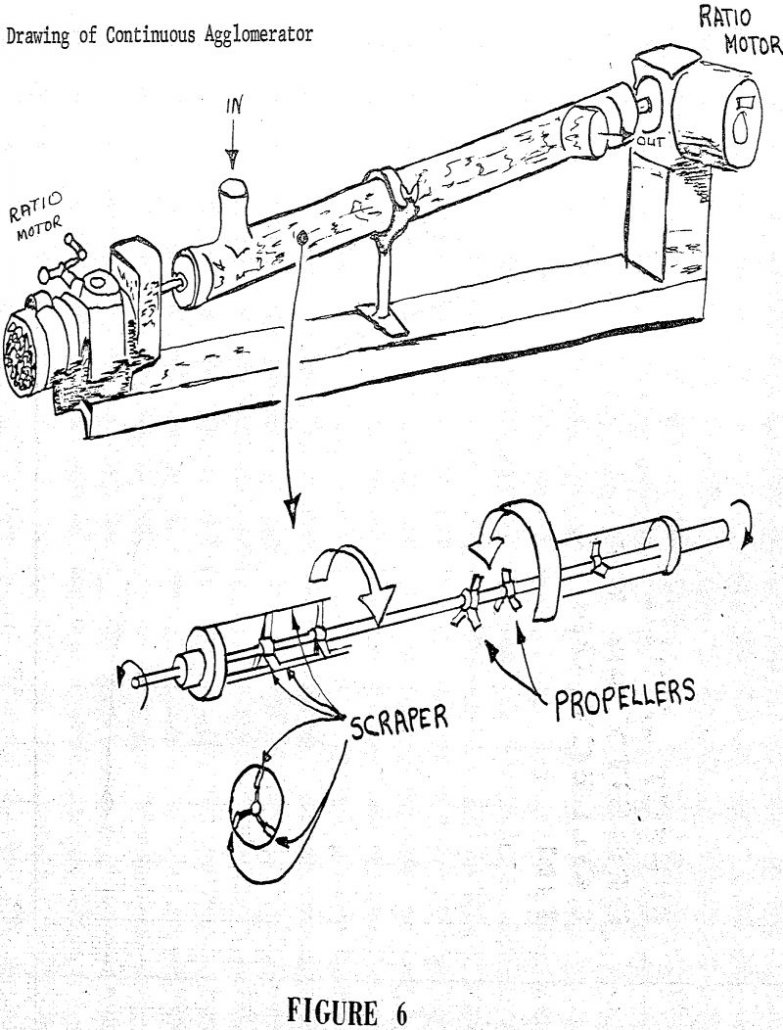

Concentration of Tin Ore by Selective Oil Agglomeration

Agglomeration, as used throughout this report, refers to a mineral dressing process in which the desired mineral, namely cassiterite, is selectively separated from the gangue minerals by attachment to a crude oil. This process is analogous to flotation except that the sought after mineral is collected by crude oil rather than air bubbles. The ore […]

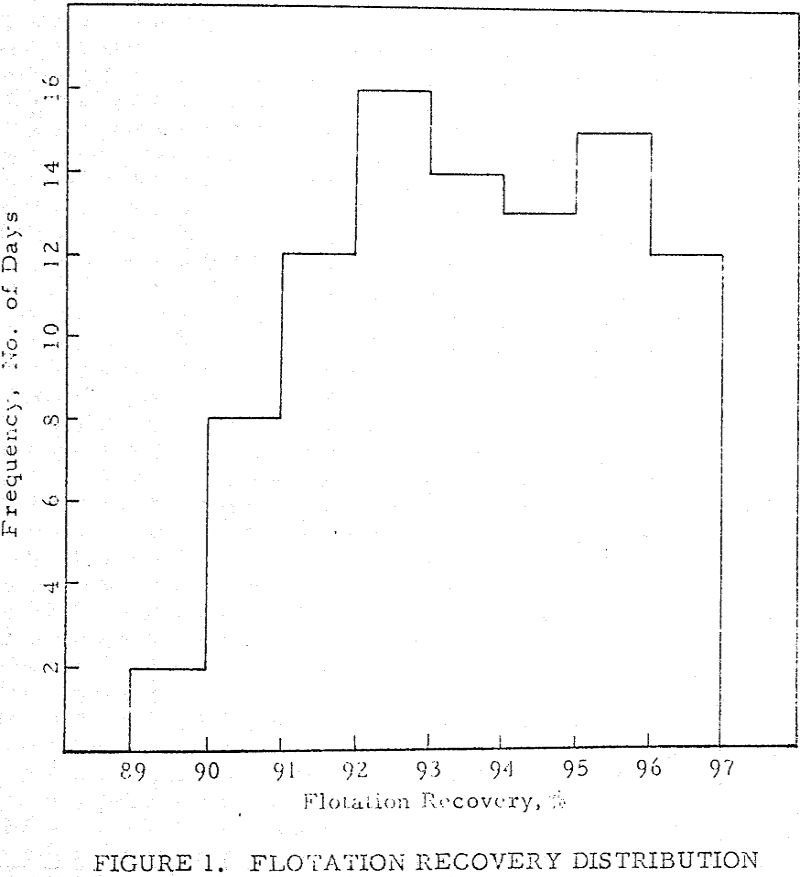

Control of Flotation Recovery using Regression Analysis

The concentrator of Bonneville Ltd. at Wendover, Utah, processes a feed obtained by solar evaporation of a brine containing sodium and potassium chlorides with minor amounts of impurities. Salable potassium chloride concentrate is produced from this feed in two steps: flotation with amine reagents to concentrate the potassium chloride, and washing of the concentrate with […]