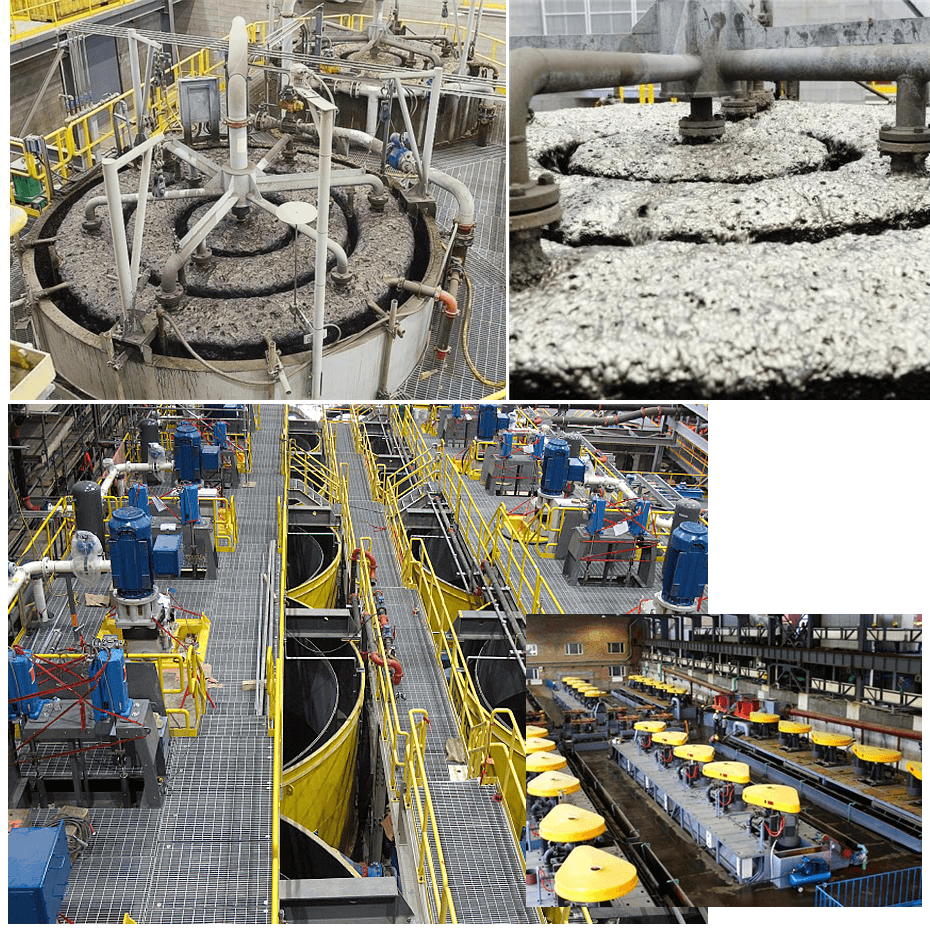

Large Scale Flotation Plants

Although froth flotation was originally developed for mineral separations in the early 20th century, the use of this process has been extended in the last twenty years. From a processing viewpoint, all of these seemingly different industrial uses can be treated using the same theoretical concepts (including equipment and basic underlying chemical reagent structures) that […]

Mineral Processing Froth Flotation

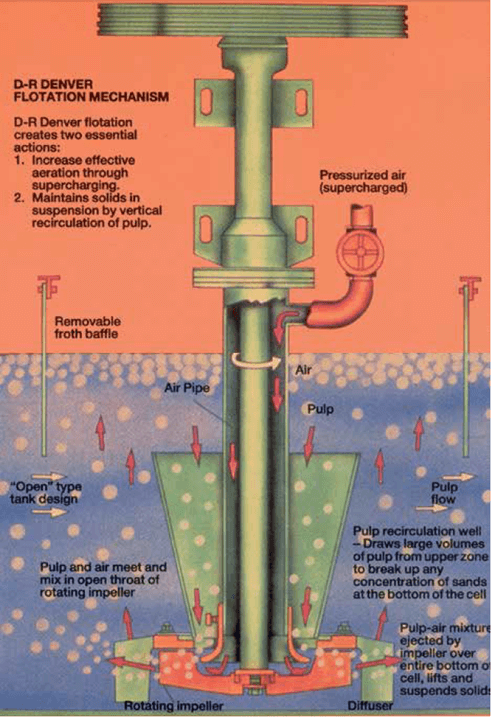

Froth Flotation is a mineral processing process achieving solid-solid separation by taking profit of the chemical attribute leading to the possibility of selectively controlling the relative surface hydrophobicities of the various components mixed in an aqueous medium. Froth flotation is the most common industrial process based on this approach. The term surface hydrophobicity refers to […]

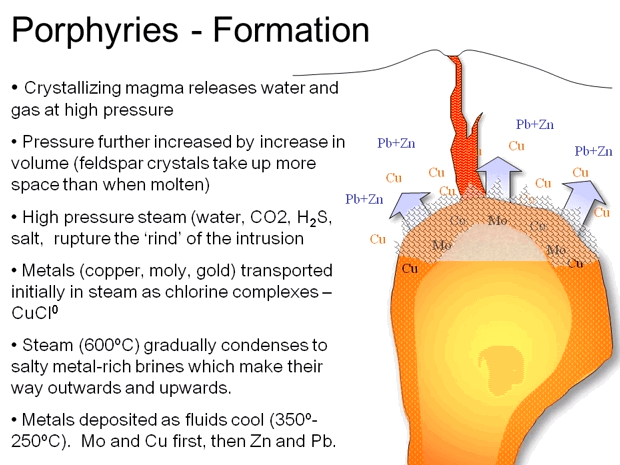

Porphyry Beer

Porphyry deposits and Beer having something in common. Porphyry ore deposit form in large intrusions that acted as magma chambers feeding active volcanoes. You will remember that as the magma chamber cools from the outside inwards, barium, feldspar and quartz crystalize out so that the remaining melts becomes enriched in metals and volatiles. The volatiles […]

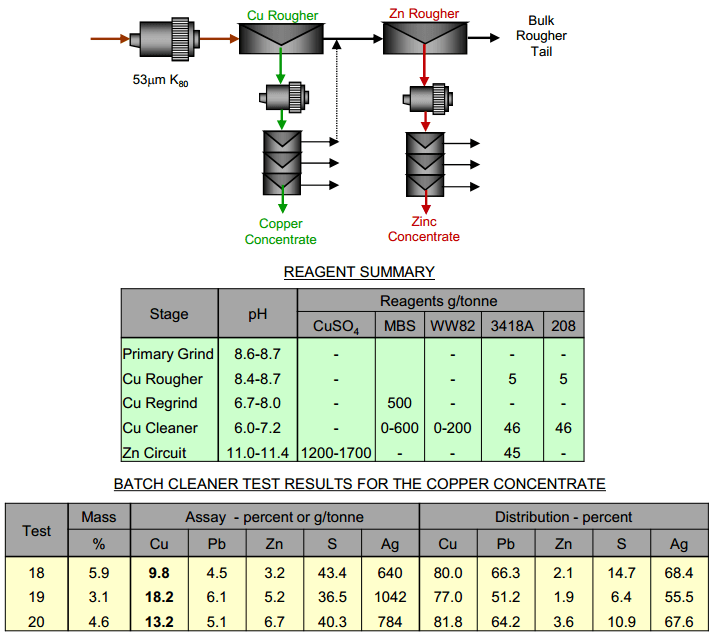

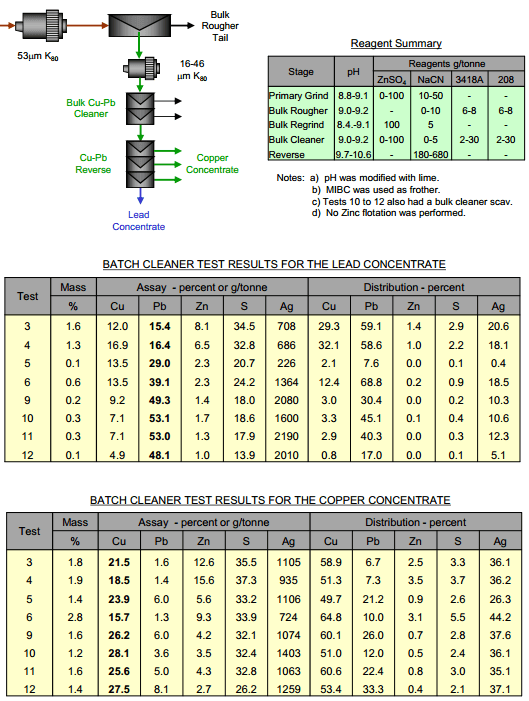

Copper – Lead Separation by Lead Depression

Another method to separate Pb from Cu is in depressing the lead away from the copper to float. Here, three batch cleaner tests were performed with additional depressants to reject more lead from the copper flotation concentrate. The baseline test utilized no MBS depression in the rougher circuit to maximize copper recovery, but MBS depression in the copper […]

How to Separate Copper from Lead by Cu Depression

How you separate Pb from Cu depends on how much of each metal is present. You best depress the metal that’s the most present, the metal you have the most of & you float the metal you have the least of. In this case, flotation of a small amount of lead from the copper concentrate would […]

Flotation Foam

The process depends upon the fact that minerals with a metallic lustre, when treated in the form of a wetted pulp, adhere to oil, while earthy minerals do not. Two distinct operations are involved; first, the separation of the metallic mineral from the gangue by means of oil; second, the extraction of the mineral from […]

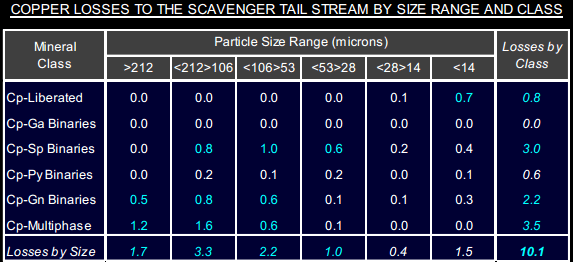

Measure and Evaluate Flotation Tail Losses

In this example, the losses of chalcopyrite to the copper scavenger tail is equivalent to about 10 percent of the copper in the ore. Losses of liberated chalcopyrite are minimal accounting for less than 1% of the copper in the feed. Most of these losses occurred as grains sized smaller than 14µm in equivalent diameter. About 55% of the […]

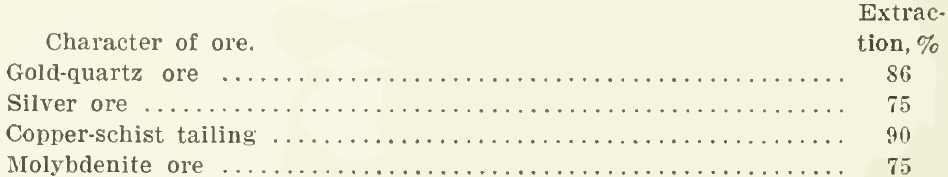

Silver & Gold Cyanide Leaching of Copper Ore

Much work has been done on the effect of copper in cyanide solutions on the leaching of gold. It is generally accepted that copper in cyanide solutions can form complex ions such as Cu(CN)2-, Cu(CN)3=, and Cu(CN)4=-, although Cu(CN)3= is considered the most probable of these. According to leach scientists, the complex having an empirical formula […]

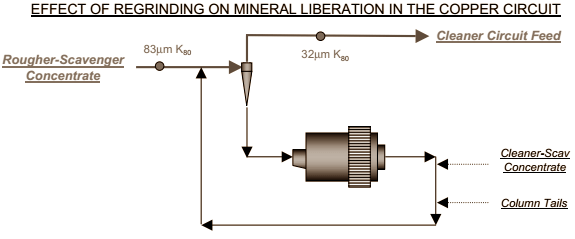

Effect of Regrinding

To ensure adequate mineral liberation is achieved ahead of the dilution cleaner circuit, a regrind mill is installed on the combined copper rougher-scavenger concentrate stream. See below the mineralogically limiting grade recovery chart, summarizing the theoretical limits to metallurgy imposed by the mineralogical associations in the cleaner circuit streams: Regrinding of the copper rougher-scavenger […]

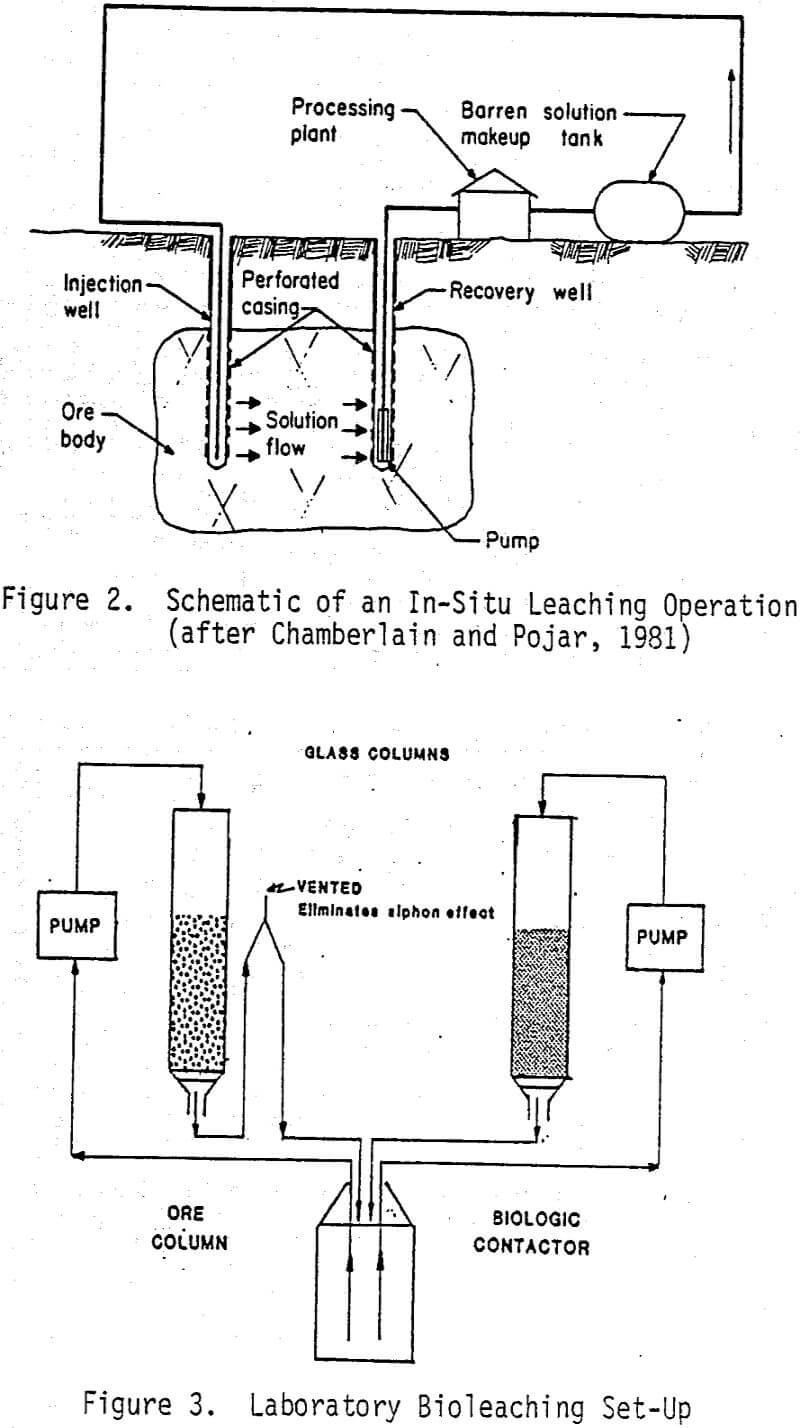

Gold & Copper Bioleaching

Bacterial Leaching of Copper Ores Several types of bacteria capable of living in an acid environment have been isolated from copper mine waters. The foremost of these are of the genus Thiobacillus (T.). Thiobacillus bacteria are acidophilic aerobic chemolithotrophs which grow most rapidly at a pH in the range of 2-3. T. ferrooxidans derive their […]