Flotation Collector Manufacturers

There are several Flotation Collector Manufacturers, but may half-a-dozen really good ones. What makes a quality may Flotation Collector supplier is the dependability and consistency of the product. Yes price matters but trusting what you buy it worth a few pennies extra. Now would you select as a Flotation Collector Manufacturer depends on what you need. If you need […]

Flotation Collectors

Simply said; a Flotation Collectors is a chemical used to make the surface of minerals, which is metallic, hydrophobic or in layman’s term ‘afraid of water’ or ‘water hating’ as others like to say. This chemical used will behaved, in a way, as a wax would when you applied it to your car. After wax (or […]

Lead Depression in Bulk Cu/Pb Flotation Concentrate (Reverse)

A series of tests were completed with bulk copper and lead flotation with the depression of lead and flotation of copper. This alternative utilized MBS as the primary depressant in both the bulk and reverse circuits. The challenge of this scheme is that the lead concentrate will be the tailings of the reverse circuit and will likely […]

Jameson Flotation Cell

The Jameson Flotation Cell Technology is owned by GlenCore. The heart of the technology is the machine’s ability to create small uniform air bubbles. Learn more at https://jamesoncell.com/EN/Downloads/Documents/brochure_en.pdf or by watching this video of a Jameson Flotation Cell operating principles.

How Froth Flotation Works

To start with I will give you a simplified description of how selective froth flotation works, lets start over again with a description of the equipment and why it works. When the grinding circuit is finished with the ore it will be ground very fine and the density of the slurry will be between 30% to 45% […]

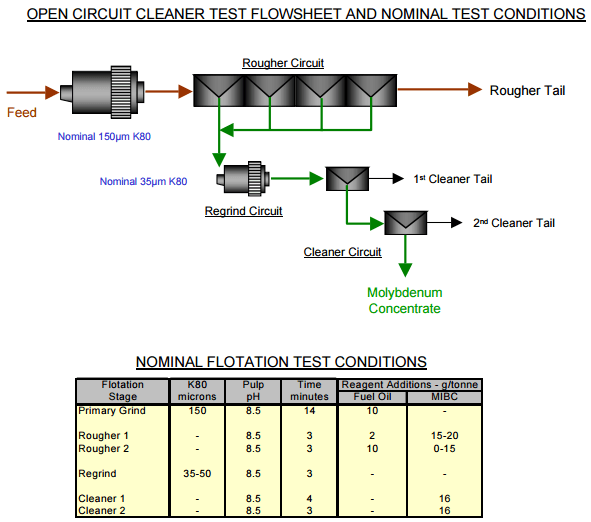

Molybdenum Flotation

A Molybdenum Flotation case study with about 6% of the molybdenum contained in the feed is present as an oxide form and about 90% of this is not recovered to the flotation concentrate. Recovery of molybdenum into the rougher concentrate varied between 90 to 95% at a concentrate grade of 2.5 to 3.7% molybdenum. The […]

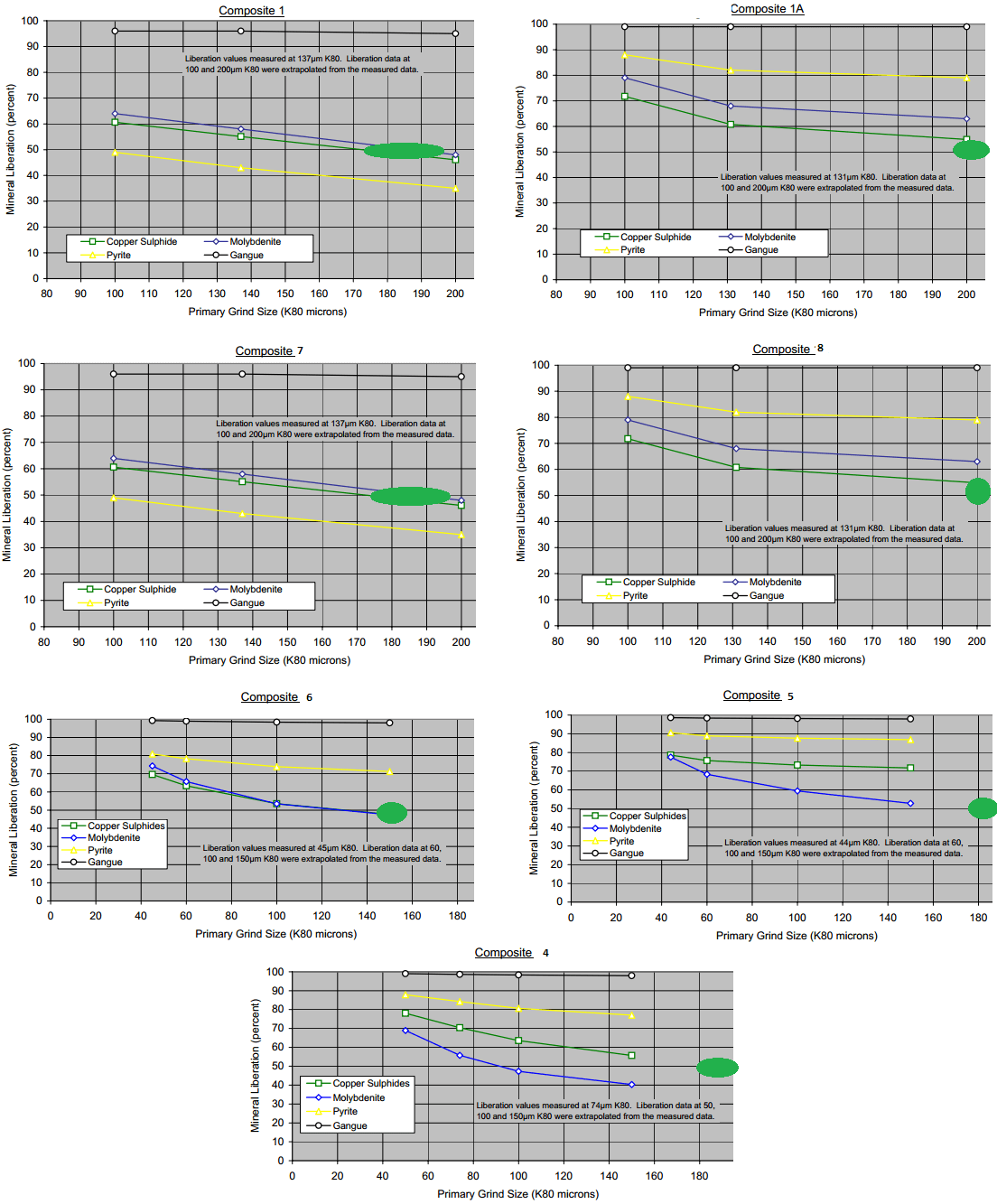

Effect Of Primary Grind Size On Mineral Liberation

The extrapolated ore fragmentation and copper sulphide liberation plots reveal that the liberation levels and hence the flotation responses of the minerals would be essentially constant across a broad range of flotation feed sizing. This observation would indicate that flotation feed sizing coarser than 200µm K80, the practical norm for copper porphyry ore processing worldwide, […]

Fluorine Dispersion

In some cases, Mica carries Fluorine. If you can not pre-float that Mica, you may want to try the Fluorine Dispersant below. Product: Oxfloat 25P – Metaphosphate As a mining chemicals for flotation treatment of multi-metallic ores Preparation: Make 2% solution in water. Dissolves readily. Dosage for good dispersion: Dosage between 100 – 1000 g/t. Product: […]

MgO Talc Depression

Product: Oxfloat D100 is of the CMC family of depressant. With the purpose of MgO Depression, this is commonly used in Southern Africa for Talc depression in PGM/Nickel flotation circuits. Also known as SODIUM CARBOXYMETHYL CELLULOSE Preparation: Make 0.5% solution in water. Add product to water into stirred beaker to prevent lumping. Allow sufficient time to dissolve. […]

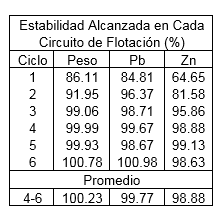

Pruebas de ciclo cerrado y su procedimiento

Una prueba de flotación de ciclo cerrado (locked cycle test en inglés) es usualmente efectuada al final de un programa de pruebas de flotación de laboratorio, y tiene como objetivo principal confirmar las mejores condiciones de flotación obtenidas en la etapa de pruebas abiertas. Para lo cual se busca evaluar la dosificación de los reactivos […]