Chemical Reaction of Copper Minerals and Cyanide

In discussing the Reaction Products from Copper Minerals and Cyanide you will find that when an excess of copper mineral is acted upon by cyanide solution, dissolution of copper continues at a decreasing rate until equilibrium is established and no more copper goes into solution. The rate will vary with the particular mineral used as […]

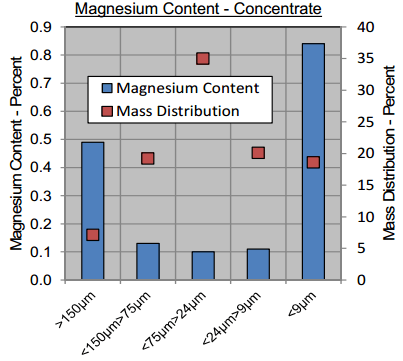

MgO in Zinc Sphalerite Concentrate Contamination

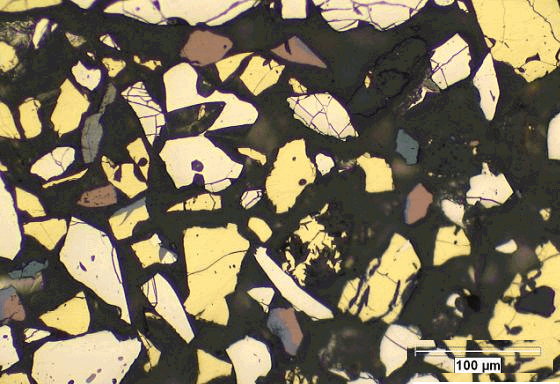

Here is how Mg is often present as Mg (magnesium oxide) in a Zinc Sphalerite Concentrate produced by froth flotation. According to typical mineralogy data obtained from Zinc concentrate (P80=90um), the MgO is located in 2 opposite regions. This concentrate contained 0.3% Mg total. Unless you want to give away your concentrate to Doe Run, you need […]

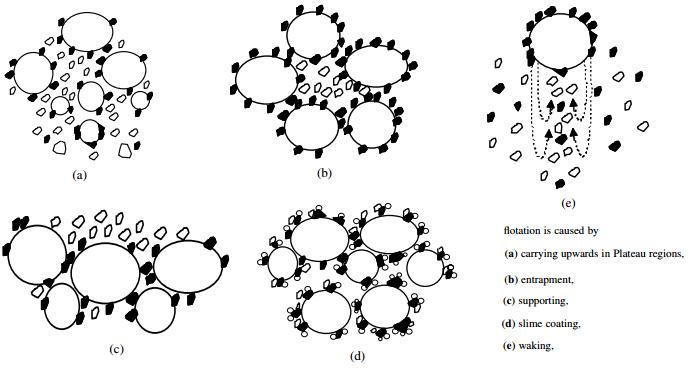

Froth Flotation Entrainment -Types and Forms

Commonly, none sulphide particles like MgO, being an oxide (or silica gangue), does not respond to flotation. For example, when MgO is found in a sulfide flotation concentrate it is either for it is associated/locked with another sulfide (pyrite/sphalerite) which has and did respond to flotation, or it has been entrained into the froth along […]

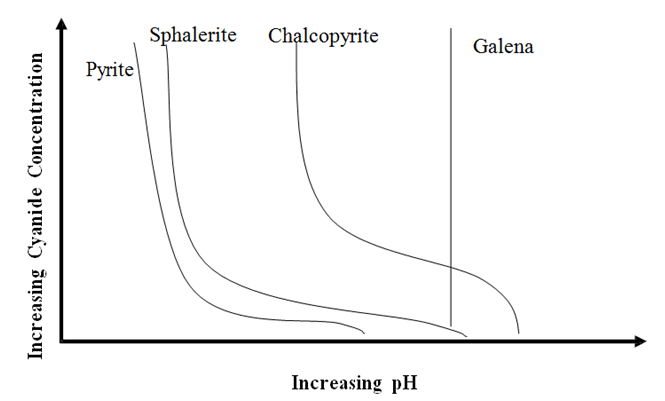

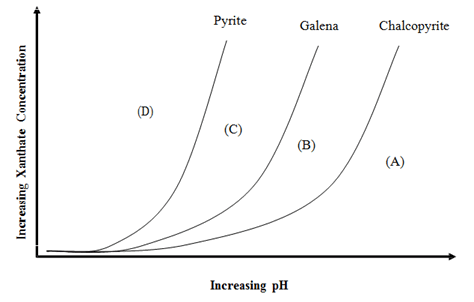

Cyanide Concentration and pH to Depress Sulphides

The chart displays how the Cyanide Concentration (how much NaCN) is needed to effectively Depress Sulphides like Pyrite, Sphalerite, Chalcopyrite but not Galena at various pH. It is pH that affects/impact the required effective concentration of cyanide. The higher the pH, the less NaCN is needed as CaO/Lime also acts as a Sulphide depressant. The use of […]

The Importance of pH in Flotation

In flotation, pH control is a vital method to control selective mineral separation. A standard depressant that is used is an Alkali. An Alkali is any substance that when mixed with Acid will neutralize each other and form a new chemical substance called a BASE. This is very important. The ore may be either alkaline […]

Litmus Paper for pH Measurement

Litmus paper is paper treated with a blue dye that turns red when in contact with acids. The measurements are taken from the degree of color the paper turns, the deeper the red, the greater is the degree of acidity. Vice versa for alkalinity, the darker the blue, the more alkaline the substance is. A […]

Controlling Flotation Reagents

A flotation operator has two areas of control over his circuit, physical, and chemical. By physical controls I mean things such as the density, grind and the pulp levels of the cells. The chemical controls are normally only the amount of reagent flow, the type of reagent, and the point oe addition. To verify the operator’s […]

How Ore Variability & Mineralogy Affects Flotation

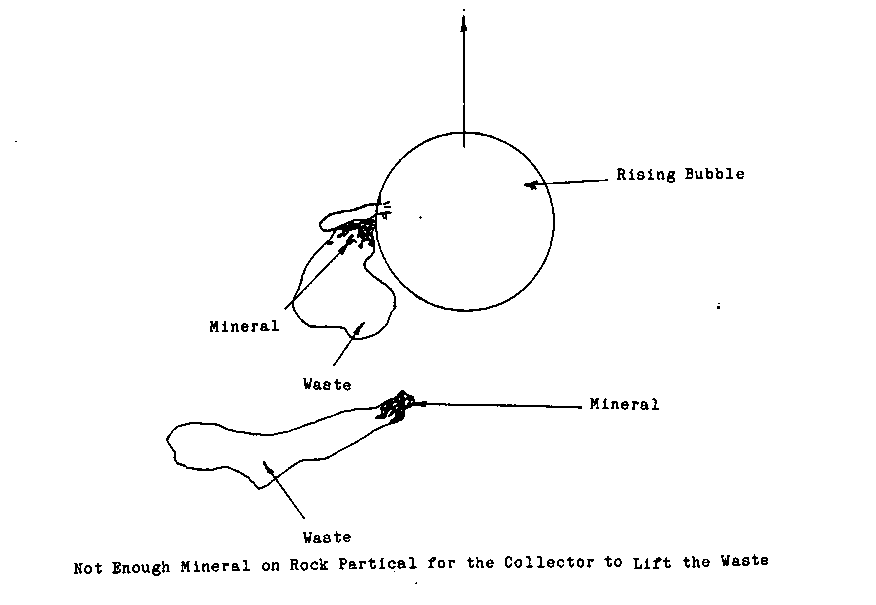

The third item on our list is ORE CHANGES. An ore change is recognized by a difference in the color of the froth, a change in the type of bubble and the amount of color that is in the froth. However these changes are not an indication of just the content of the ore fluctuating. […]

How Flotation Density Affects Recovery Performance

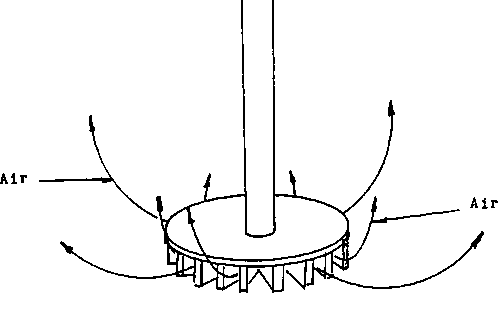

The next way that density effects the circuit is in the dispersal quality of the air and reagents. If the density is heavy, the chemicals may not be mixed thoroughly throughout the ore due to the poorer agitation. This may cause mineral losses due to the mineral not being able to come into contact with […]

How Mill Tonnage Affects Flotation and its Reagent Dosage

The first item on our list that an operator will be concerned with is the TONNAGE. There is a misconception common amongst operators to the effect that when reagents are added to the ore being processed, you are treating the mineral, or the amount of mineral that is in the ore. That is not correct. […]