Stage Addition of Flotation Reagents

In Laboratory, the quality of the concentrate floated in the 1st minute of rougher improves if reagent/collector is stage-added. Stage-adding collector involves adding ½ the total dosage to the 1st cell + ¼ to the 2nd and ¼ to the 3rd or 4th cell. It can be expected a similar metallurgical behavior could be […]

Basic Slurry Sampling Method

The first rule of sampling technique is the sample must be REPRESENTATIVE. What this means is that the sample must be a true indication of the content of material being sampled. To accomplish the most basics of all slurry sampling method, this the operator has a few guidelines to follow. First, you need get a […]

Basic Flotation Circuit Design

Let’s, proceed to Basic Flotation CIRCUIT DESIGN. To understand flotation it is necessary to learn some new terminology. To do this let’s look at a simple schematic of the circuit we were just working with. Let’s start with the CLASSIFIER OVERFLOW, once the classifier is finished with it enters the CONDITIONER TANK. This tank […]

Adjust Weir Gate Level on Flotation Cell/Bank

If we examine the froth column of this bank of cells you will notice that the column becomes SHALLOWER from cell to cell. This is to capture the particles that are lightly mineralized, and is floating very low in the froth. The last cell will have the shallowest froth column, in fact in many cases, the […]

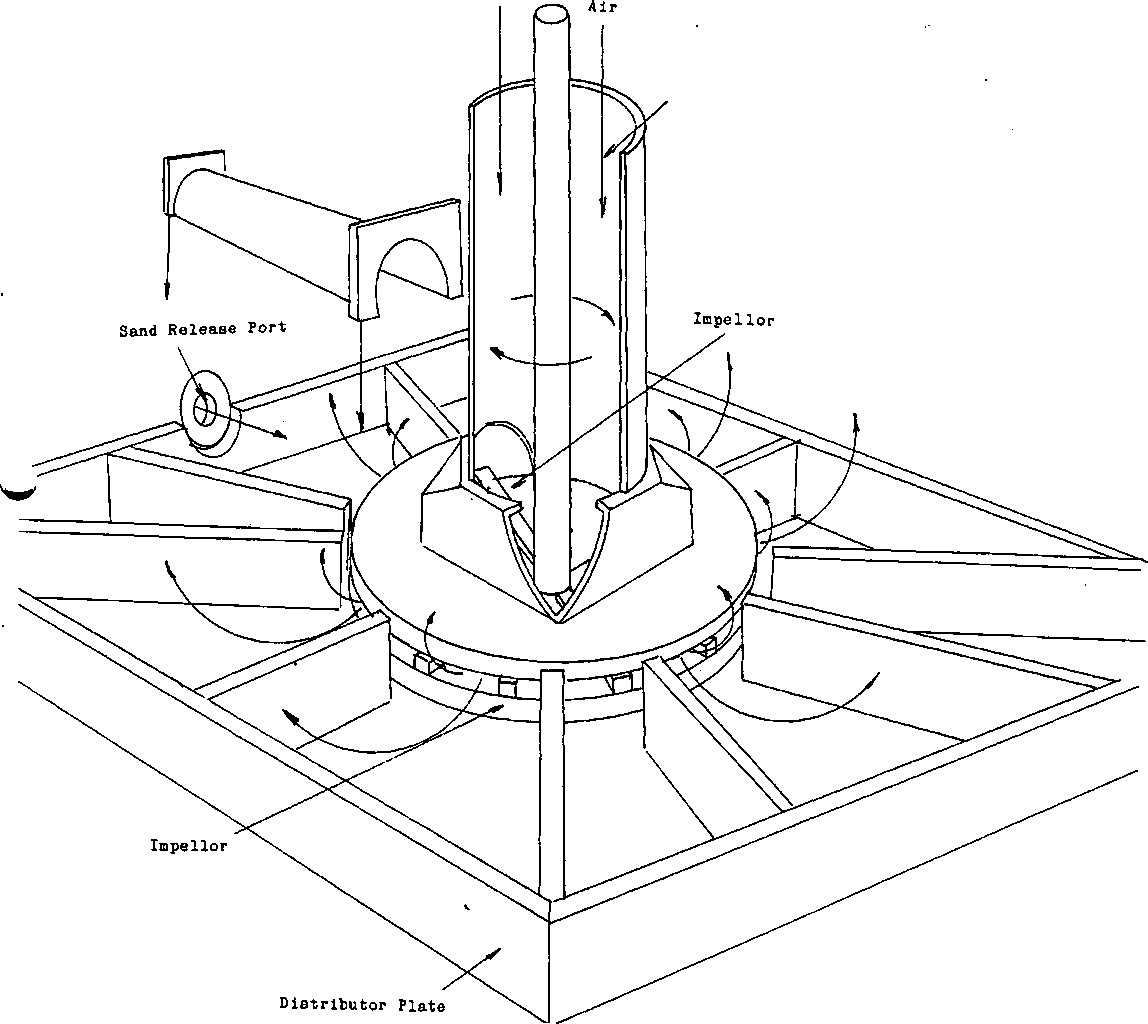

Flotation Cell/Bank Sand Port

In every cell there is the need to allow the SANDS to escape. The sands are the particles that didn’t become ground fine enough. NO matter how efficient the classifier is it will not be one hundred percent effective. There will always be aware factor, where in the circuit that the cell is, and operator […]

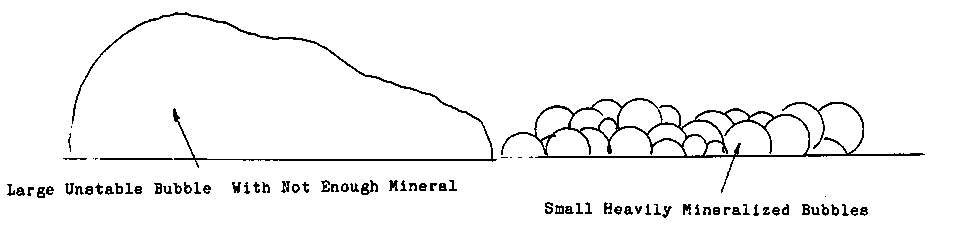

Adjusting Pulp and Air Levels to get good Froth Movement

Any time that you have an overloaded froth condition the OVERFLOW that is going over the side of the cell will slow down as the froth column begins to collapse under the weight of the mineral. The first corrective reaction is to raise the pulp level or add air to the cells to quickly increase […]

Optimum Flotation Reagent Addition Rate (Dosage)

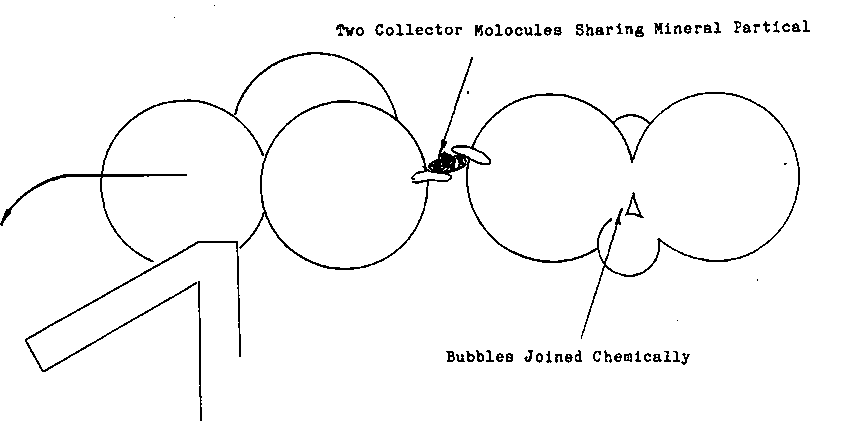

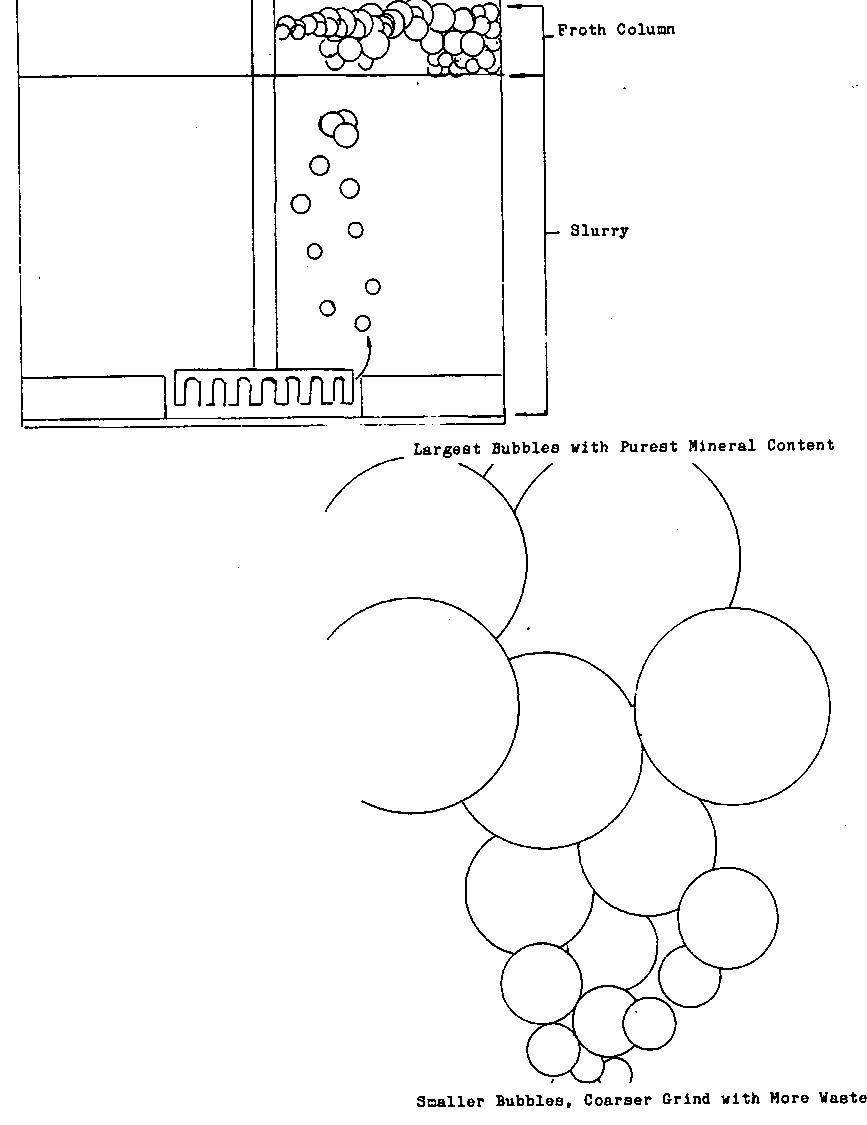

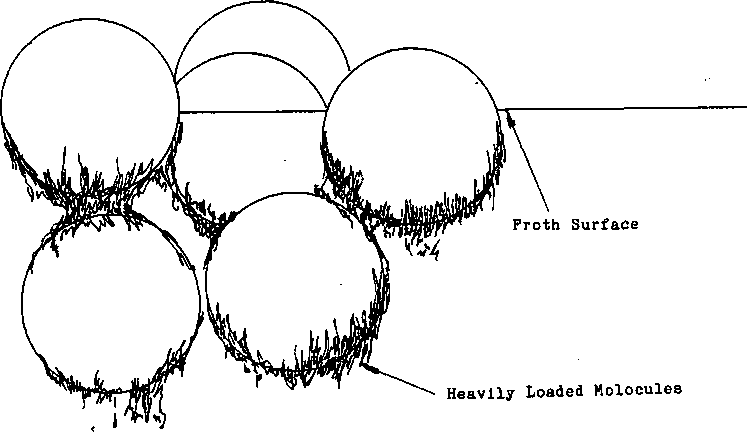

By now you are aware of the importance of the effect that the reagents have on single bubbles. Now we will begin to show you how the bubbles effect each other. In the cell the air, the reagents, the mineral and the impellor agitation all combine to create what is known as a FROTH COLUMN. […]

Flotation Frother Dosage

Now for the FROTHER, if there is TOO LITTLE frother the bubbles will become small and the speed of the overflow will be slow. If this condition continues the speed will become slower and slower as the collector overloads the bubble. Soon the froth won’t move at all. The colour will remain correct. On the […]

Flotation Collector Dosage – Over/Under Collection of Froth

What happens when there is too much flotation collector, how do you know and how can to estimate? The bubble will react as if there is too little depressant. Froth bubbles will get smaller and closer together, but the unlike the depressant it won’t cause the mineral to fall off of the bubble due to overloading. […]

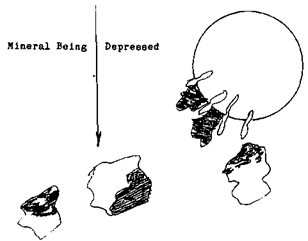

Flotation Depressants

First let’s change the amount of the Flotation Depressants used. The valuable mineral that isn’t liberated from the unwanted mineral will begin to be depressed along with the waste. For the floatation operator, the change that will become most apparent is, that the color of the froth will begin to reflect more of the wanted mineral’s […]