Evaluating Copper Rougher-Scavenger Flotation Circuit Grade/Recovery Results

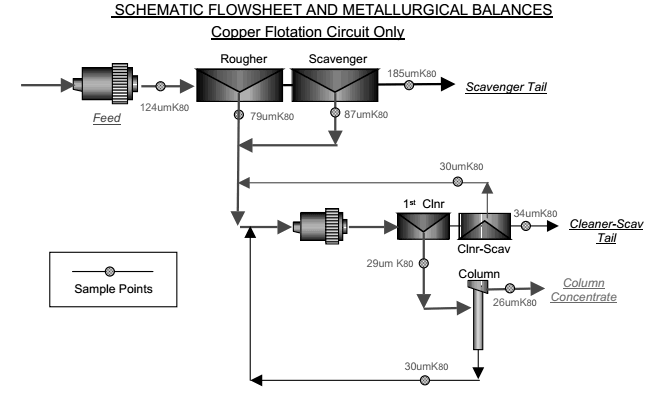

A modal examination of the products produced by the copper flotation rougher-scavenger circuit reveal important information regarding the limits to the efficiency of the process, imposed by mineralogy, fragmentation and flotation capacity. Let’s discusses various aspects of rougher flotation circuit performance and how to evaluate its results . Prior to compositing the individual downbank rougher […]

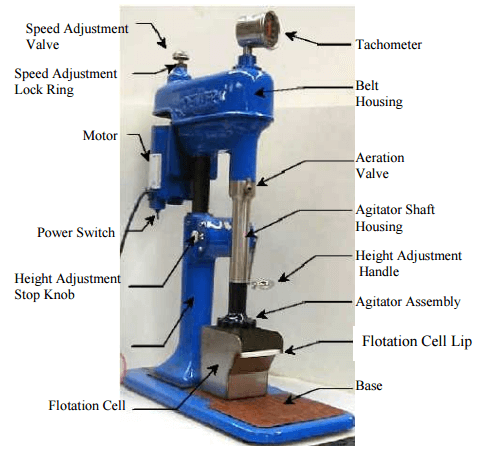

Selecting or Choosing a Lab Flotation Machine Model

The model’s choice of a laboratory flotation machine depends on three things; What work you want to do with the machine Who you have to operate the machine How much you have to spend If its just for some ‘hot’ plant floats and some basic metallurgical testing onsite then my personal favorite is the old […]

The effect of particle size on the rate of flotation

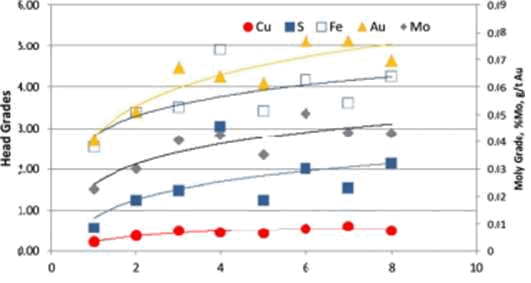

Low Molybdenum Recovery in Copper-Moly Flotation Circuit

In a flotation locked cycle test, a poor/low moly recovery was obtained at 47.3% as it appeared that molybdenum had not reached equilibrium. The calculated head grade trend, shown in Figure 8-28 indicates that the moly and most of the other elements had not reached convergence when the test was terminated. Figure 8-29 shows the […]

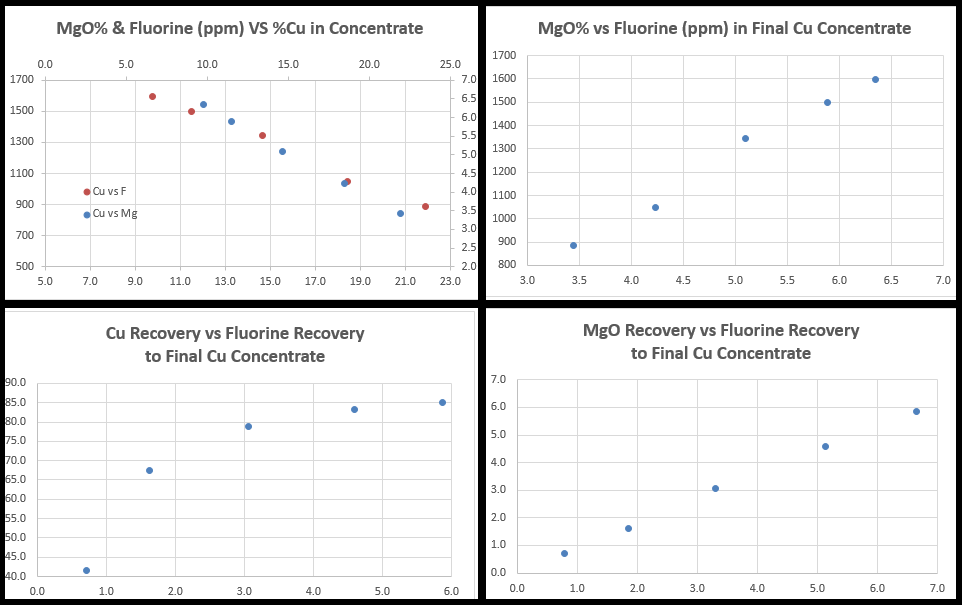

Understand Fluorine in Copper Concentrate (F in Cu Conc)

A copper flotation concentrate is over limit on Fluorine (F) content and Contamination. When assaying and plotting Copper (Cu) from times concentrates and the related fluorine and Magnesium Oxide (MgO) assays in various ways as shown below; one can see the obvious relationships. In the case, reducing Fluorine content and contamination of the copper conc […]

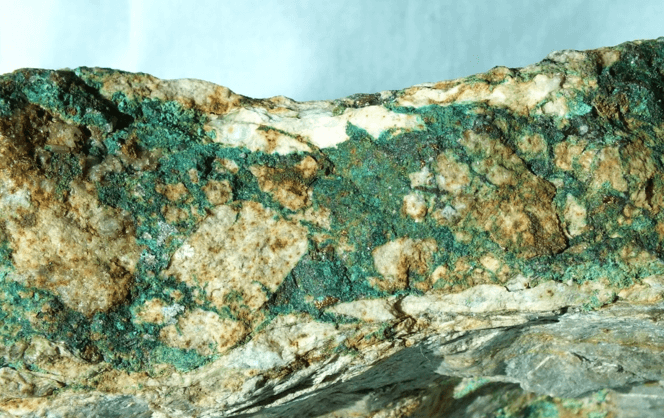

Eliminating Copper from Gold Ore

When reviewing Methods of Eliminating Copper from Gold Ores we see that several methods have been suggested to eliminate copper from ores prior to cyanidation. Preliminary extraction of the copper with sulphuric or sulphurous acids may be applicable to ores containing oxidized copper minerals such as malachite, azurite and chrysocolla but these acids have but little […]

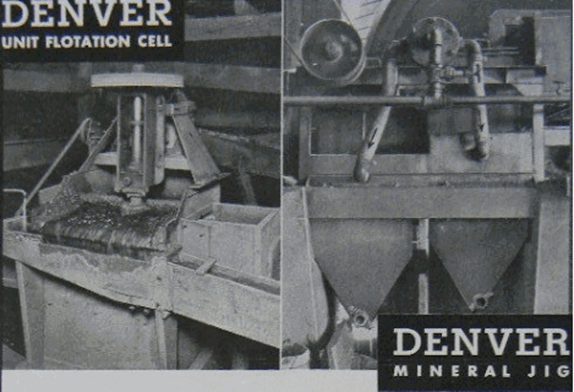

Flotation and Gravity for Better Recovery

HIGHER RECOVERIES ALWAYS RESULT when freed mineral is removed from the fine grinding circuit. Here are the two profit making machines which have today made this step standard practice in milling plants the world over. The Denver unit Flotation cell has definite place in every flotation plant where lead, copper, zinc or other sulphides are […]

AGITAIR Flotation Machine

Scientific separation and recovery of the values in strategic metals is AGITAIR’s flotation machines’ vital contribution to metal production worldwide. By improving results and lowering costs, it has become a factor in conservation and profit building that leading metallurgists have recognized. These are well authenticated facts demonstrated daily in hundreds of mills-large and small-throughout America and […]

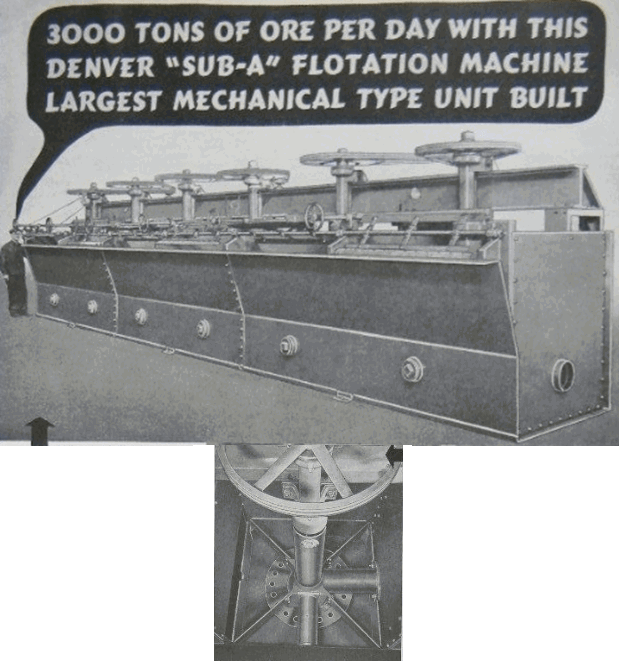

Denver “Sub-A” Flotation Machine

No application is too large, too difficult, or too complex for this Denver “Sub-A” flotation Machine. Now ONE Denver “Sub-A” will handle the pulp from several large grinding circuits, thus simplifying the flotation operation. This Denver “Sub-A” will handle 3,000 tons of dry ore at 40% solids down to 1,000 tons at 15% solids. The […]

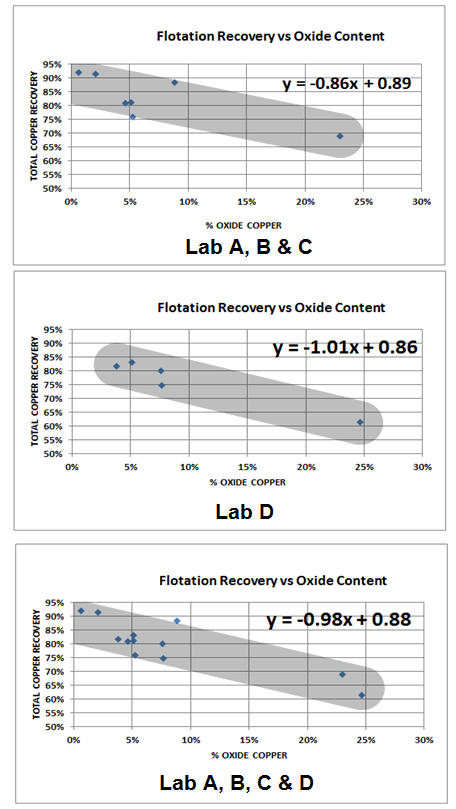

Copper Flotation Recovery Rates of Oxidized Ores

A crude display of how oxide content (copper) affects the overall recovery of any given ores. Below are flotation recovery responses of 5 different ores from North and South America. In all cases, the recovery VS %Oxide relationship is obvious. Samples vary from 0.4% to 1.6% total copper. The heavy oxide chart (4th one down) […]