Silver Flotation Concentrate Leaching and Filtration Circuits

Producing a Silver Flotation concentrate from this EXAMPLE Argentite (cubic silver sulfide (Ag2S)) Flotation Circuit enters the first of four successive Argentite leach tanks. The purpose of this leach circuit is to dissolve the silver and gold recovered in the Flotation Circuit. A high strength solution of sodium cyanide, air, and lime are added to the […]

Flotation Circuit Startup and Shutdown Procedure

In preparation for this EXAMPLE Startup, the following items must be checked before the associated conditioning and flotation equipment and circuit is started. Ensure that all applicable reagent systems are operational, and that the conditioning tank agitators, flotation feed pumps, flotation mechanisms, flotation blower, and the rougher concentrate, cleaner tails, and argentite leach feed pumps are operational. The samplers […]

Silver Mineral Argentite Flotation Circuit

Solid residue from the second filtration stage is repulped with reclaim water to 35% solids, and is pumped to our EXAMPLE Conditioning and Argentite Flotation Circuit which is a process for the recovery of this Silver Mineral. A large portion of the silver in the ore will not have been leached in the initial grinding and […]

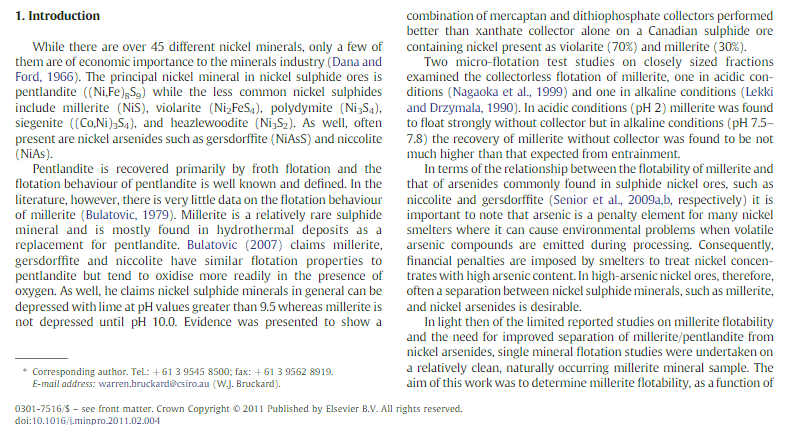

Millerite (NiS) Serapation from Pentlandite and Chalcopyrite

While there are over 45 different nickel minerals, only a few of them are of economic importance to the minerals industry. The principal nickel mineral in nickel sulphide ores is pentlandite ((Ni,Fe)8S9) while the less common nickel sulphides include millerite (NiS). violarite (Ni2FeS4), polydymite (Ni3S4), siegenitc {(Co,Ni)3S4), and heazlewoodite (Ni3S2). As well, often present are […]

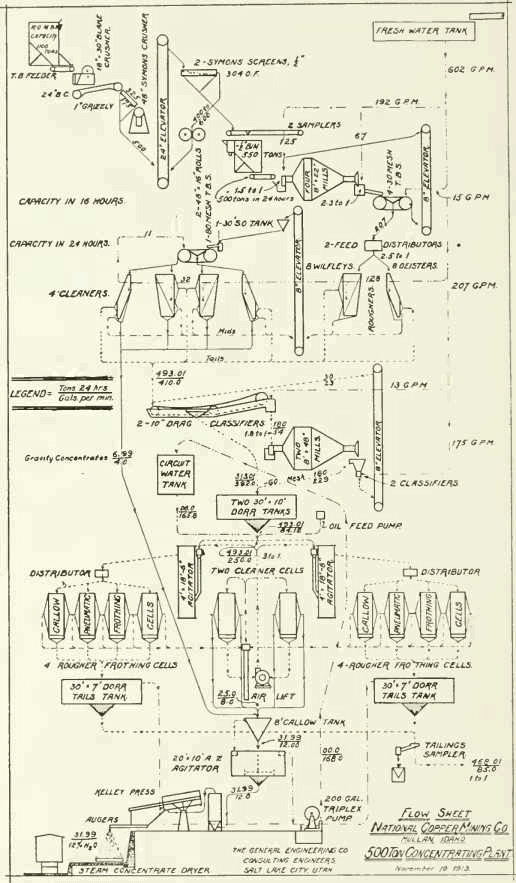

Flotation Methods in Mineral Processing: Enhancing Recovery and Efficiency | 911 Metallurgist

The FLOTATION PROCESS is one of the commonest methods of extracting the valuable minerals from certain classes of ores, and it is generally more efficient as regards the recovery of the minerals than any other process applicable to the treatment of similar types of ores. The metallic contents of the minerals are recovered from the […]

Why do Minerals Float

I was very much interested in reading an article by Charles T. Durell, appearing in the Mining and Scientific Press of September 18, under the caption ‘”Why do Minerals Float?’ However, I find myself unable to agree with Mr. Durell’s line of argument, and for the following reasons: In the first place I believe that […]

Flotation Oils

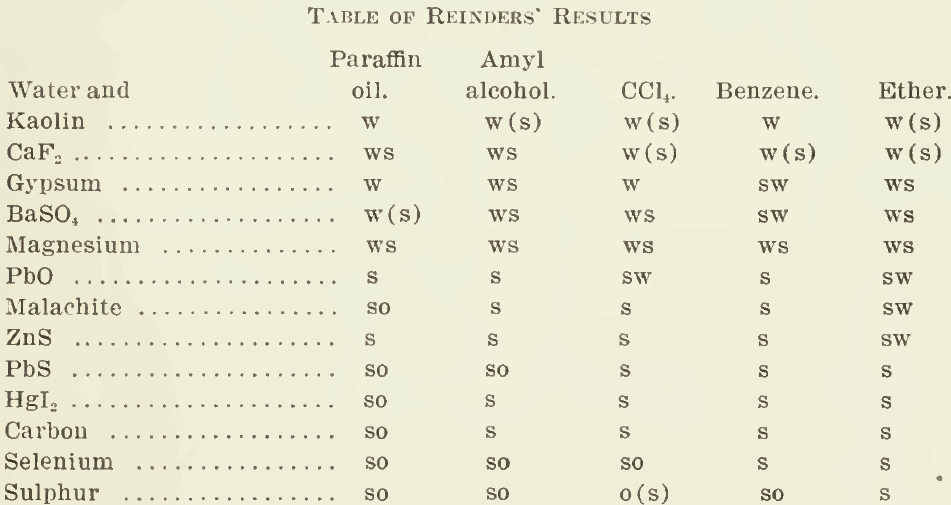

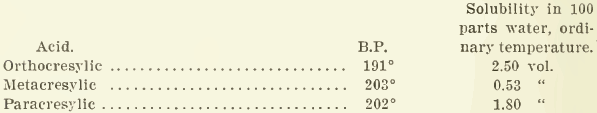

The work of the past two years at many mills in the United States, Mexico, and South America, has done much to prove the suitability of flotation processes to the recovery of the sulphide ores of copper, and to indicate the best reagents. In a general way, it may be said that oils of mineral […]

Processing Gold Ore by Flotation

APPLICATION OF FLOTATION TO GOLD ORE A flotation plant is being erected at the Falcon mine, Rhodesia, to treat ore containing gold and copper. With the exception of the Mt. Morgan, the Etheridge, and the Great Fitzroy mines, Queensland, I have not heard of the flotation process being used successfully to treat ore containing an […]

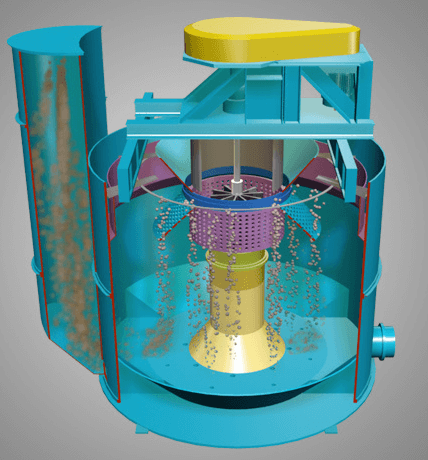

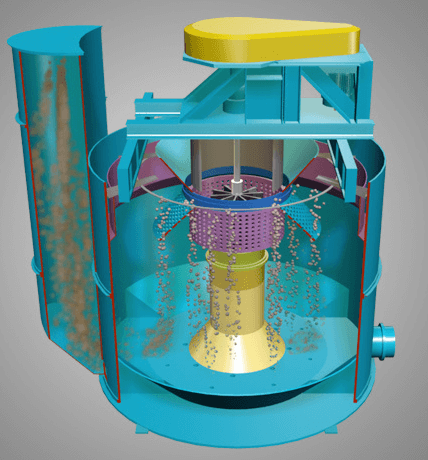

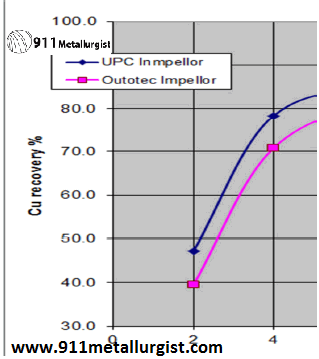

Better Agitation for Better Recovery

A laboratory trial to first prove the concept was followed by full scale plant trials to prove the efficacy of the design compared to a current market leader rotor/stator supplier. LABORATORY TRIAL The laboratory trial was carried out at the AMML laboratory in Gosford by Graeme Sheldon on a copper ore from Queensland. This trial was purely […]

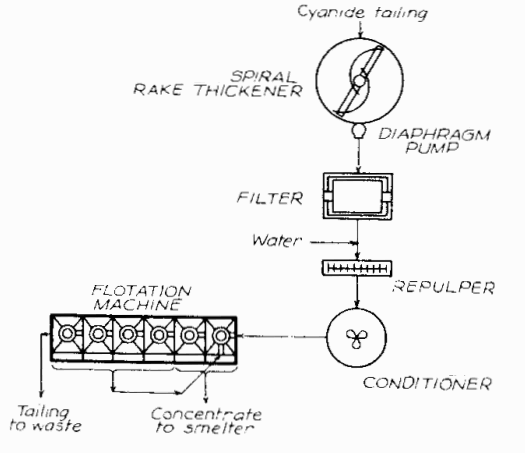

Flotation Cyanidation CIL Tailings

This simple process flowsheet allows for Flotation Cyanidation Tailings in cases where ore bodies at depth have become more refractory and dotation ahead of cyanidation would call for major and expensive mill alterations, the sulphide minerals containing the undissolved precious metals can be recovered by flotation and shipped to the smelter. In some cases it […]