Electrochemistry of Flotation

If one turns to ‘Elementary Lessons in Electricity and Magnetism,’ by Silvanus Thompson and studies the fundamental principles of frictional electricity, as given in Chapter 1 of Electrochemistry of Flotation, a clearer idea of the causes of ‘flotation’ may be obtained. After seeing a few experiments, such as were performed at the Case School of […]

Cyanide Leaching of Flotation Concentrate

When Charles Butters began to take up the work of flotation in our Oakland laboratory, one of the first points brought to our attention was the treatment of the concentrate produced by flotation; J. E. Clennell was accordingly instructed to undertake the researches detailed in the present paper. The whole value of the process hinges […]

Air Injected Froth Flotation

The manifestation of the force of surface tension is a phenomenon that shows itself as a tendency of any liquid body—we may confine ourselves to a liquid—to assume that shape in which it has the least surface. It is a well-known fact that in the form of a sphere the ratio of surface to volume […]

Surface Tension and Salts in Solution

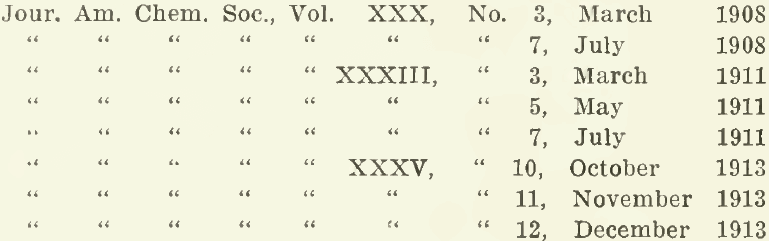

Surface tension has been threshed out pretty thoroughly by articles appearing in the Journals of the American Chemical Society, beginning in 1908. These articles deal with the drop-weight method (weight of a falling drop) for the determination of molecular weight, critical temperature, and surface tension, and they describe the apparatus used. The work was started […]

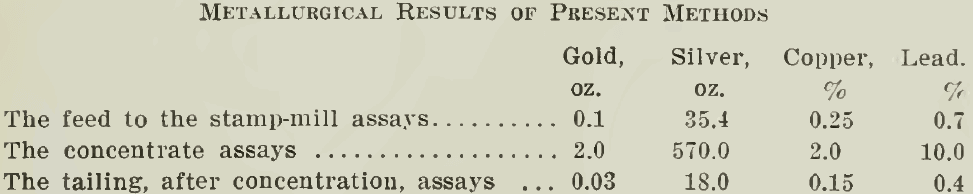

Gold & Silver Recovery from Mexican Ore

The mill receives 200 tons per clay of crude mine ore. After being crushed to 2-inch size, this ore is passed over a picking-belt, where one ton of high-grade ore and four tons of waste are removed each day. The remaining 195 tons of second-class ore is crushed in stamp-batteries to pass a 4-mesh screen. […]

Flotation of Copper Ores

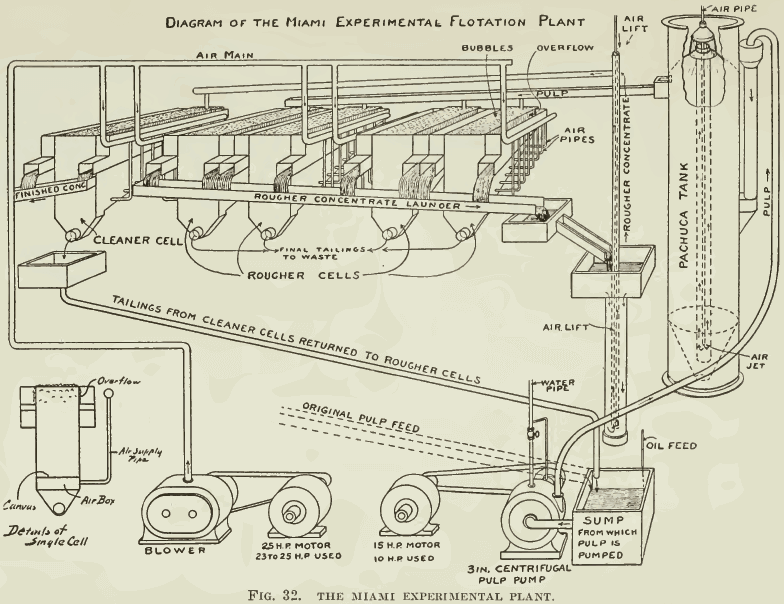

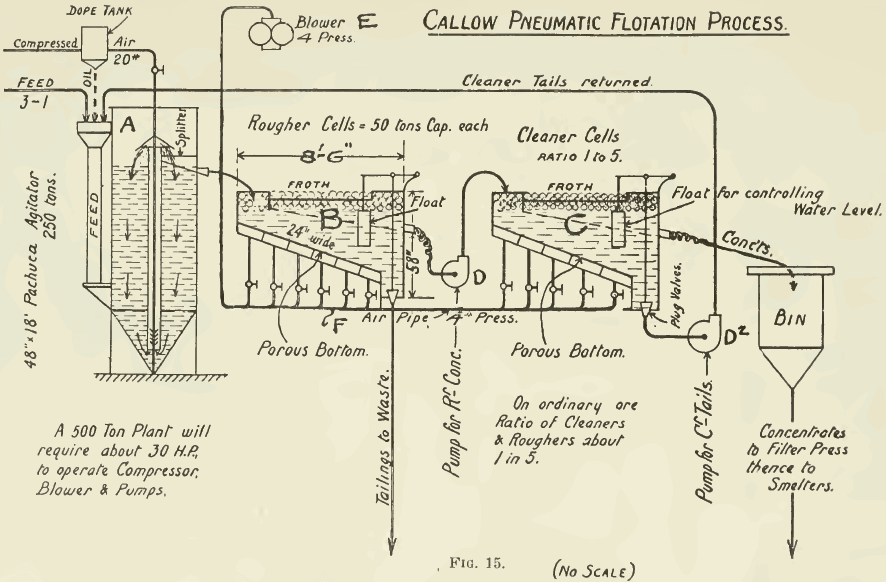

Pneumatic flotation is already fully established in a number of places and the results in comparison with the other and older schemes fully justify the opinion of your correspondent that it constitutes the most distinct advance in flotation in recent years. The first pneumatic-flotation plant in this country was erected by me in February 1914 […]

Process Air & Plant Air

Process air is supplied to the process by two 150 HP, 1200 nm3/hr, 250 kPa compressors. Each compressor is a totally self-contained package. Each compressor is an electric motor driven, single stage screw compressor complete with accessories piped, wired and baseplate mounted. Under normal operating conditions only one of the two compressors will be used. […]

Preparing Flotation Reagents

The following flotation reagent mixing system is typical for the flotation reagent mixing systems: A-208, Xanthate and Sodium Silicate. The reagent mix tanks, for the above mentioned reagents, are located on the basement floor. Feed chutes from the main operating floor carry dry or wet reagents to each mix tank. Either reclaim or fresh water is […]

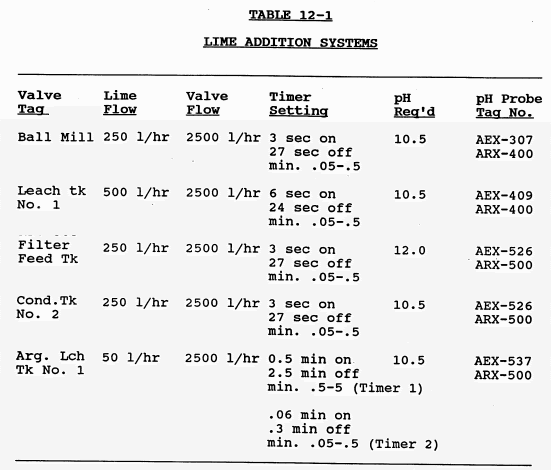

Lime Addition System

The lime system is a packaged unit which operates automatically and continuously. The equipment provided in the package includes the lime silo, rotary feeder, lime slaker and lime slurry mix tank and agitator. The lime system is equipped with its own PLC which automatically provides lime slurry for the process. Hydrated lime is stored in a […]

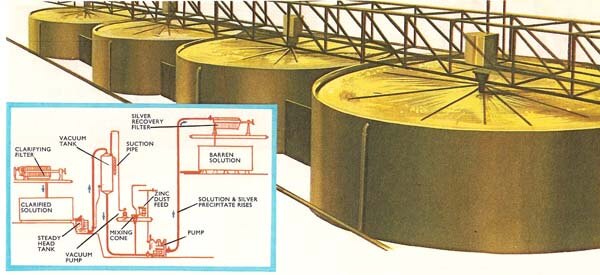

Silver Sulphide Leaching & Filtration Circuit Startup & Shutdown Procedures

Details of good silver sulphide leaching and filtration circuit operation and instructions for sequencing and preparing for startup. The following items must be checked before the equipment in this EXAMPLE Argentite Leaching Circuit is started. The leach tank agitators should be running. Check that the Argentite filter feed pump, drum filter, repulper and tailings sampling pump […]