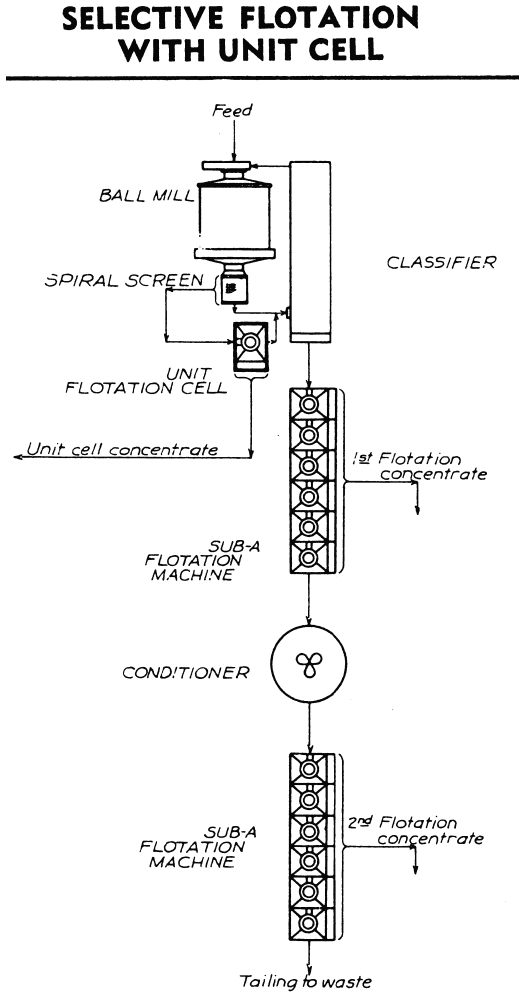

Flash Flotation in Gold Circuit – 2 Product Processing

DESCRIPTION: Flash Unit Flotation Cell in selective “gold” flotation circuit. ORE TREATED: The widest application of this flowsheet is on lead-zinc ore treatment, although it also can be applied to some gold ores as well as molybdenum ores containing other sulphides. This circuit is very similar to the now closed Cominco Polaris mill has; an ‘in-grinding’ […]

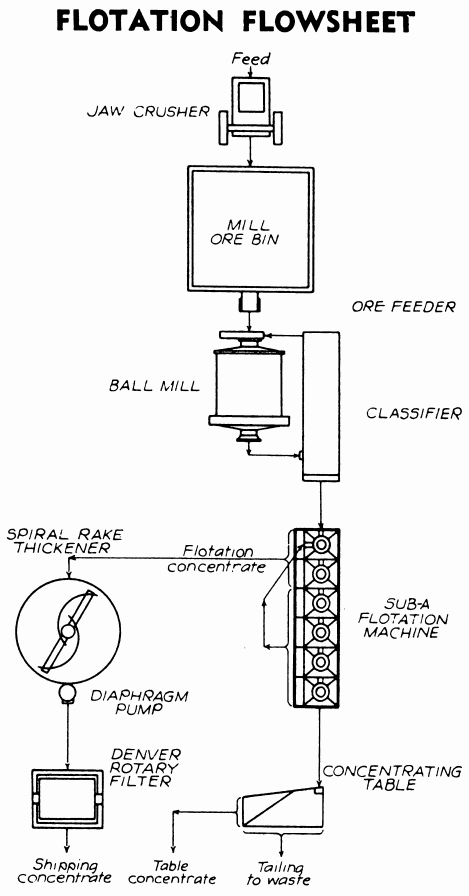

Simple Flotation Flowsheet – 1 Product

DESCRIPTION: A Straight flotation flowsheet of one product showing flotation machine treating ground and classified pulp. ORE TREATED: Base metal ores containing a single valuable mineral such as a copper or lead sulphide, and complex gold and silver ores, are economically handled with this simple flowsheet. It is commonly used where fine grinding is required and […]

Flotation using Acid

The mineral that is two millimetres and under in size is sent to the Hardinge mills for re-grinding. These mills are 10 ft. diam. by 4 ft. long, and are in closed circuit with simplex Dorr classifiers, one classifier to each mill, 6 mills to the section, and 8 sections in the establishment. The overflow […]

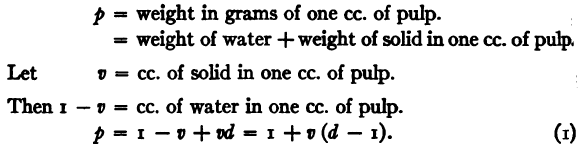

Pulp Formulas & Metallurgical Formulas

Definitions. “Pulp,” in flotation terminology, is a freely-flowing mixture of powdered ore and water. “Pulp density,” when the phrase is applied properly, indicates the specific gravity of the pulp. “Percentage of solids” means the ratio, expressed as a percentage, of the weight of the solids in a pulp to the total weight of pulp. “Pulp consistency” is the ratio, […]

Flotation Controlling Factors

The object of this paper is to offer some suggestions to assist metallurgists to supervise the operations of flotation plants. We do not yet thoroughly understand what “flotation” is, or “why minerals float,” and all attempts that have been made to explain the phenomena have been based on theory or imagination, and have not been capable […]

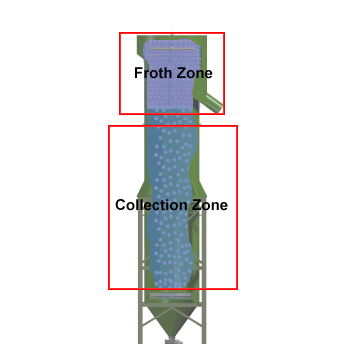

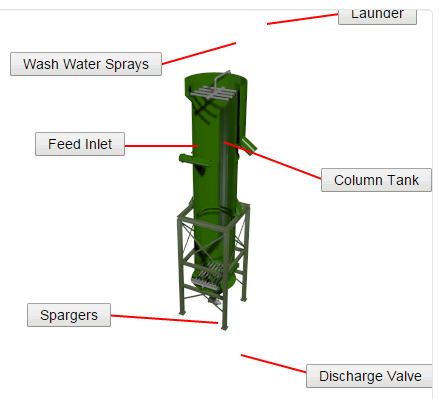

Column Flotation Cells

Column flotation cells, like mechanical cells, are used to perform mineral separations. Column cells do not use mechanical agitation (impellers). Instead, mixing is achieved by the turbulence provided by the rising bubbles. Columns are mostly used to produce final grade concentrates because they are capable of high selectivity. Other features which distinguish them from mechanical […]

Column Cells

Flotation cells can be divided in two groups: mechanical and pneumatic machines. The first group comprises the traditional cells which employ a mechanical agitation, and the second group is related to pneumatic cells which do not have mechanical devices for maintaining the slurry under agitation. Columns offer the advantages of counter current contact between slurry […]

Lead-Bismuth Flotation

Often we hear that copper concentrates have contaminants which affect the incomes to be obtained by commercialization. Well, one of the worst contaminant is bismuth because is difficult to remove during smelting process and the metallic copper to be obtained at the end of the process will be brittle and consequently its mechanical properties will be […]

Why do Metals Float

Some of the fundamental principles of this concentration ‘upside down,’ as it may be termed, being such a new method, have been overlooked. There has been such a mad scramble to get results in advance of the ‘other fellow,’ and to penetrate the cloud of secrecy enforced by patent litigation, that there has been little […]

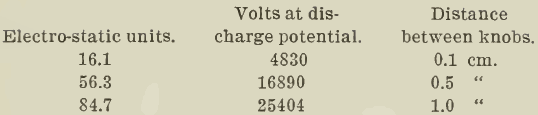

Electrostatic of Minerals and Flotation

The development of every new metallurgical method is accompanied by a host of contradictory statements and widely differing opinions, but it is only by the elimination and correlation of parts of recorded observations that a particular process approaches a state of perfection. The theory of flotation has called forth a number of articles, each writer […]