Effects of Soluble Metals Flotation

In concentration by flotation, the soluble components of an ore may play an important role. Occasionally ores that are shown by preliminary test to be unsuitable for flotation may be treated by the process after the soluble ingredients have been removed by decantation. On the other hand, excellent results may be obtained on certain ores […]

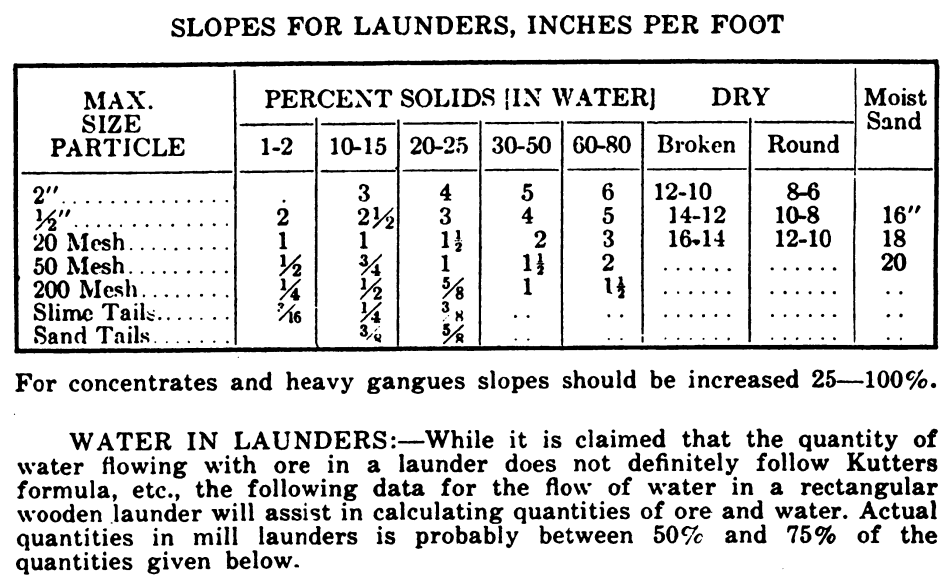

Slope of Flotation Slurry Launders for Froth Flow

Launders should have high enough velocities to prevent particles from settling, or if they fall to the bottom, to keep them rolling and sliding. The depth of water should not be much over the diameter of the largest rolling particles. For concentrates and heavy gangues slopes should be increased 25—100%. SPRAY WATER IN LAUNDERS:—While it is […]

Preferential Flotation

‘Preferential’ flotation is a specialized application of the flotative principle in the separation of minerals from their ores. It gained its first wide use as a name for certain methods of floating minerals in connection with the Horwood process mentioned below. ‘Selective’ flotation has come to mean (by common consent) the flotation of valuable minerals […]

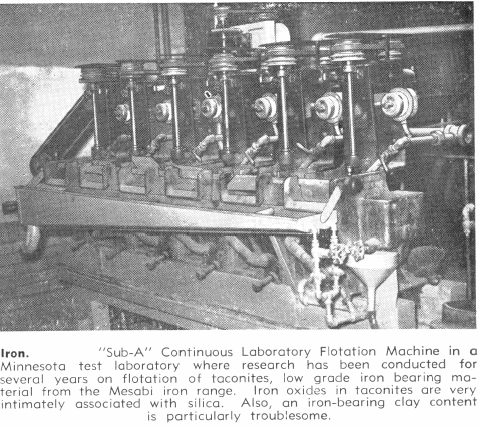

D1 Laboratory Flotation Cell

USED DENVER D-1 LAB FLOTATION MACHINE (4) TANKS TWO STAINLESS STEEL TWO PLASTIC TACHOMETER NEW BEARINGS INSTALLED NEW ADJUSTABLE DRIVE SHEAVE INSTALLED

Milling Methods and Costs

Flotation of Oxidized Silver-Lead Ore

Flotation of Oxide Silver + Oxide Lead Ore

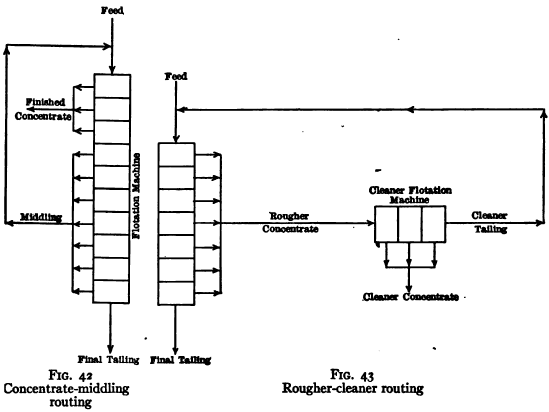

Flotation Flowsheets

Typical flotation flowsheets may be classified into two general types on the basis of the part which flotation plays in the mill treatment scheme and each of these classes may be again sub-divided on the basis of the method of routing the pulp through the flotation machines. On the first basis, a flow-sheet is of the “primary” type when […]

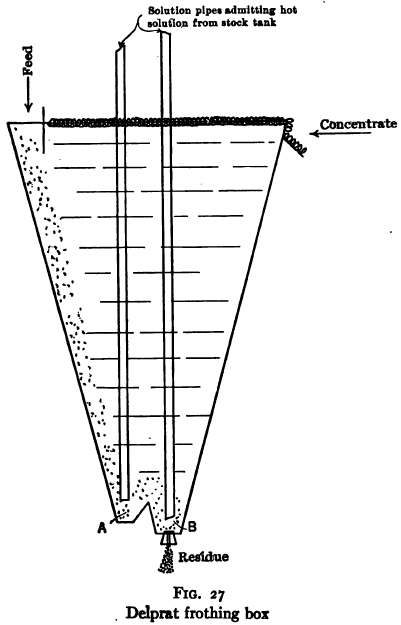

Froth Flotation and its Machines

Pulp-body-concentration Processes The Potter and Delprat processes Now combined and known by the name Potter-Delprat process, are described in U. S. patents 735,071, 763,662, 768,035 and 776,145. As at present practiced the dewatered pulp is fed into an apparatus of the type shown in Fig. 27, which is from 10 to 20 ft. deep. Hot sulphuric acid […]

Laboratory Scale Flotation Tests & Flotation Plant Results

Translation of laboratory results into terms of plant/mill-scale operations is, in the usual case, less difficult in flotation than in gravity concentration, and in all cases more certain than where chemical reactions such as occur in leaching and precipitation operations are concerned. Any flotation result that can be obtained in a laboratory machine can be obtained […]

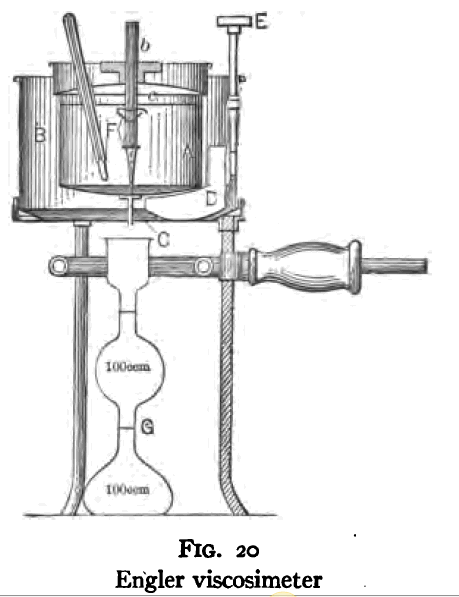

Testing Flotation Oils and Frothers

The usual purpose of oil testing in flotation work is to determine that the oil in question is similar in physical properties and therefore probably in its behavior in the flotation cell to a given prior shipment, or in order to set specifications for flotation oil purchase. The following tests will give such information. Color Color is […]