Flotation Blowers

Rotary Blower for pressure and vacuum service is universally used with gas or oil burners, furnaces forges, ovens, etc. Two inter-engaging impellers, rotating in opposite directions draw air into the pockets between the impellers and the case, and force this air into the discharge pipe. The amount of air displaced by these impellers at each revolution […]

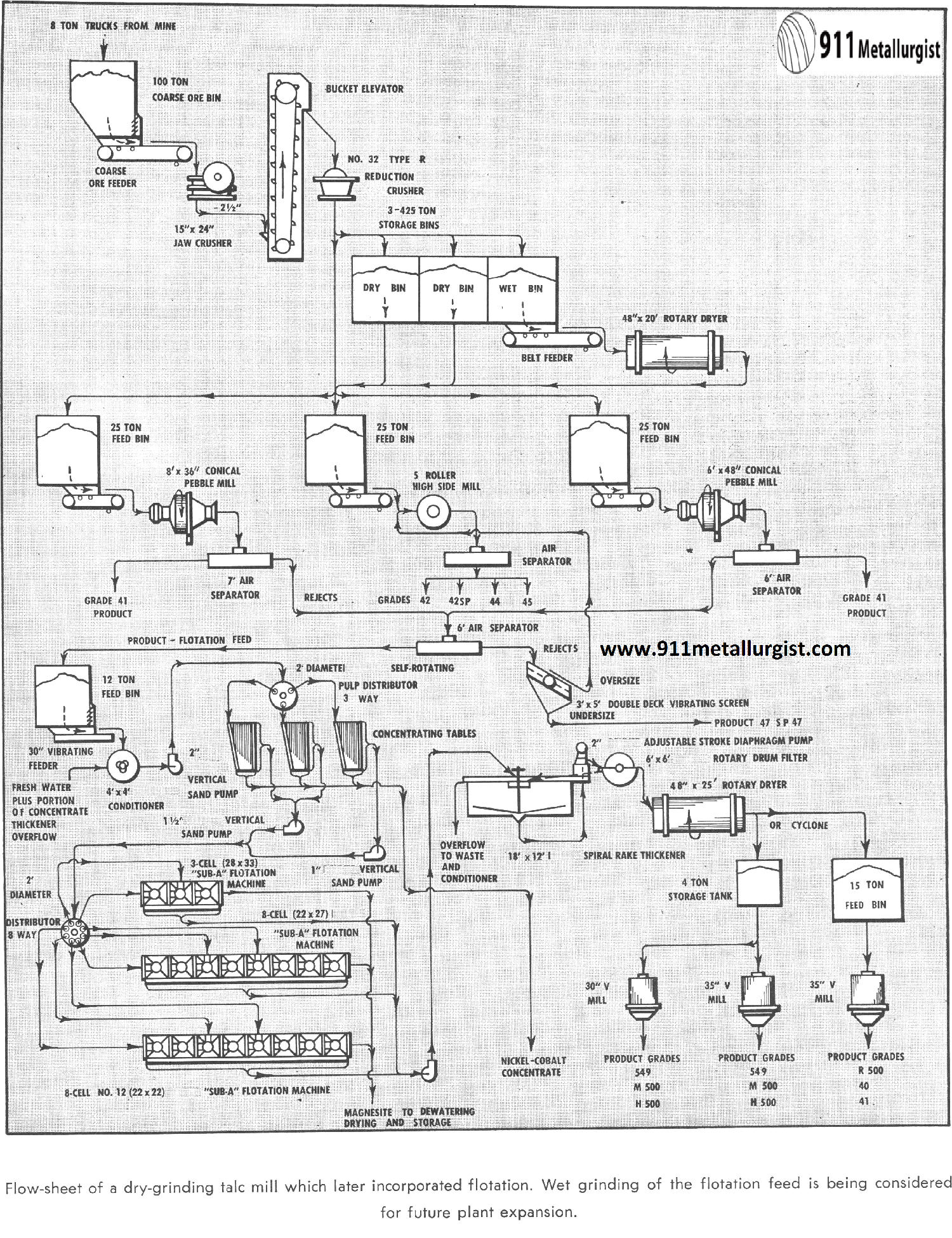

Talc Beneficiation Process – Flotation

Talc Market Specifications Talc has a wide variety of uses and markets, specifications for which call for certain standards of grain size, shape, color, chemical and mineral composition, weight per unit volume, oil absorption and hardness. The paint industry is by far the largest user of talc, but the roofing, ceramics, paper, rubber, cosmetics, textile […]

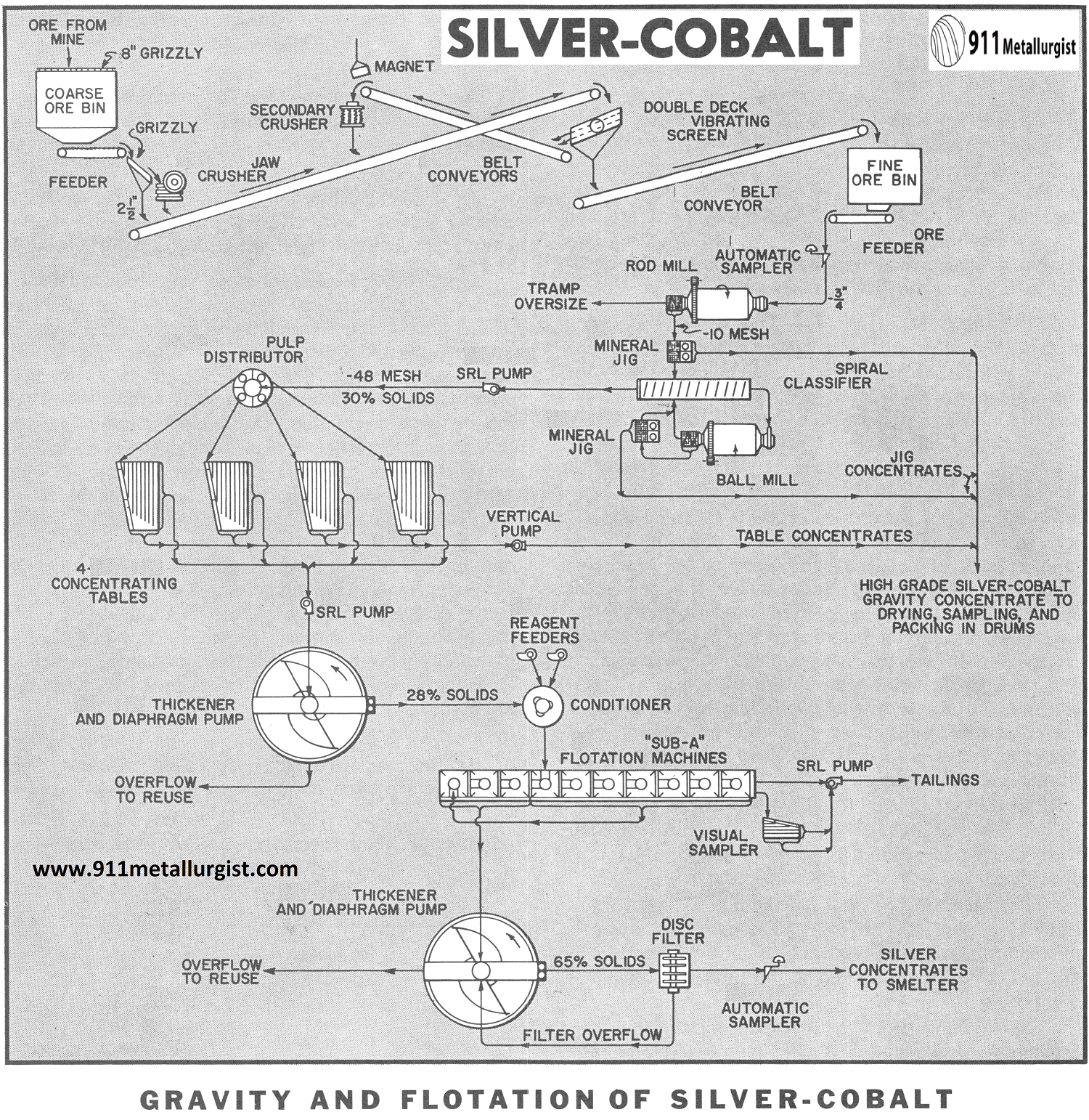

Silver & Cobalt Processing by Gravity and Flotation

The treatment of complex silver cobalt ores occurring with antimony and arsenic require special metallurgical processing to produce concentrates most advantageous for smelting. Gravity concentration is used to initially recover a high percentage of the native silver and cobalt. The concentrate is marketed and payment received for these constituents. Flotation treatment of the gravity tailing […]

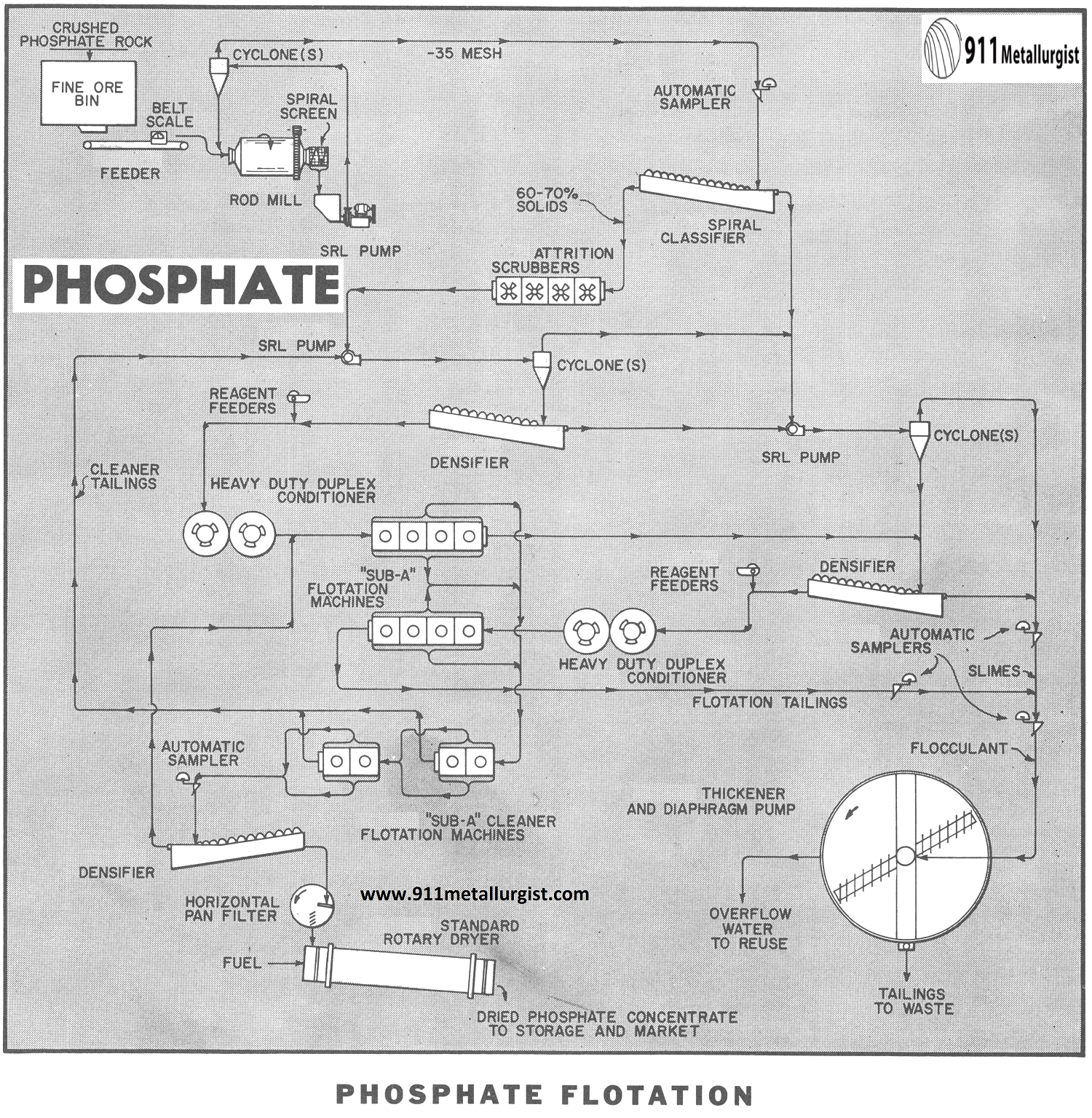

Phosphate Flotation

The phosphate-bearing formations in the West constitute relatively thick beds of phosphatic sandstones and shales that can be mined on a large scale employing open pit methods. The mineralogical characteristics vary considerably and require various treatment conditions for specific areas. For Phosphate, flotation is, in general, very important to upgrading the phosphate rock and is employed in […]

Different Types of Flotation Cells

Flotation is both a science and an art. It brings together many complex variables. Such basic factors as knowledge of mineral structure, chemical reagents, pH of mill water, pulp density, temperature, technical skills of the operator, the dependability of the flotation machine, as well as a host of other factors which affect the flotation of […]

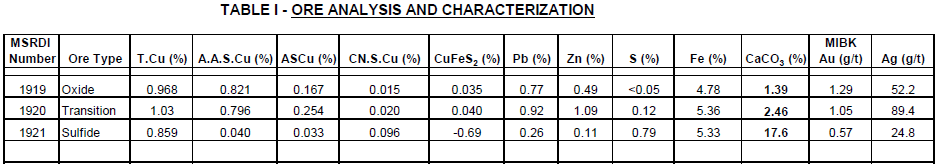

LPF Process Metallurgical Testing

EXECUTIVE SUMMARY A Metallurgical Laboratory had completed preliminary economic studies on various processing options applicable to the Minerals Project in South America, containing oxide, transition and sulfide ore reserves. These included heap leaching with SX-EW; use of Roast-Leach-EW of sulfide concentrates to produce CuSO4 crystals; and potential application of the Leach-Precipitation-Flotation (LPF) option to treat […]

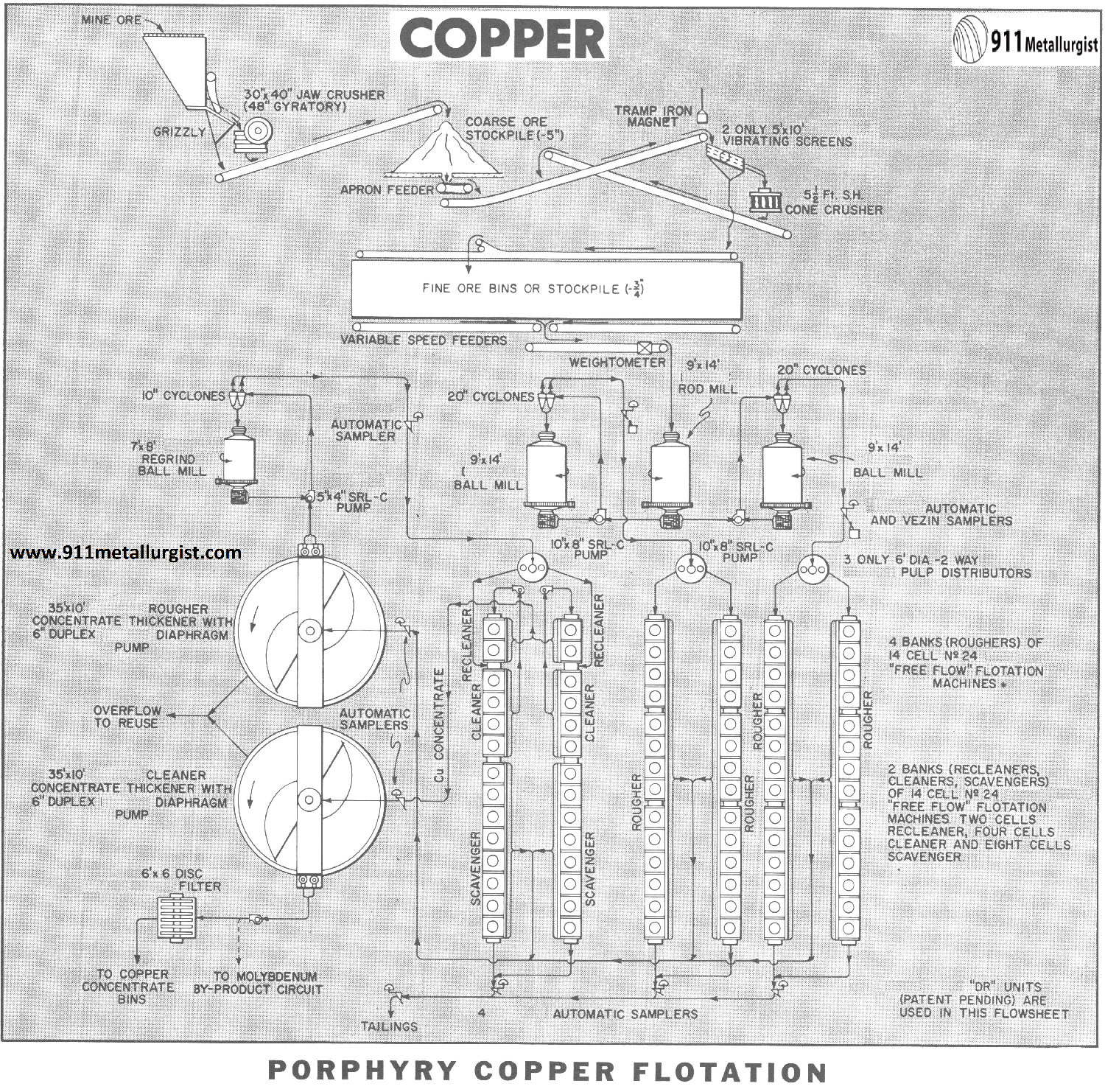

Copper Flotation

Although basic porphyry copper flotation and metallurgy has remained virtually the same for many years, the processing equipment as well as design of the mills has continually been improved to increase production while reducing operating and maintenance costs. Also, considerable attention is paid to automatic sensing devices and automatic controls in order to assure maximum […]

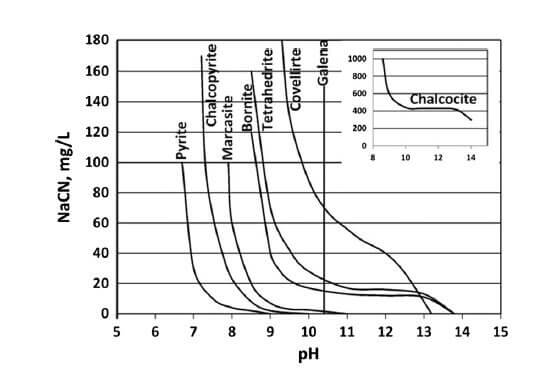

Effect of NaCN Cyanide Dosage on Depression of Sulphide Minerals VS pH

At the dosage of collector (not shown but relatively low), it is indicating galena will not float above pH 10.4, and it is not affected by NaCN. What you have to be careful about is that these lines all move if you increase or decrease the collector dosage. For example, you can get pyrite to […]

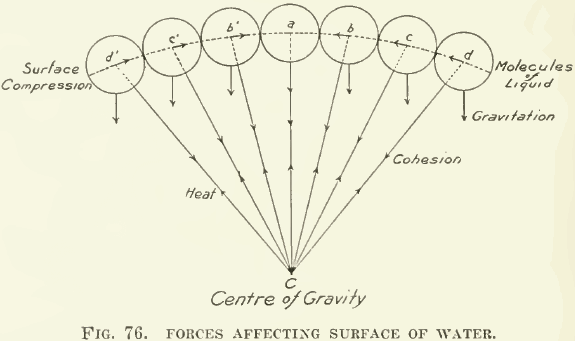

Flotation Bubble Surface Compression

At the meeting of the local membership of the American Institute of Mining Engineers on December 14 last the question was asked by one of the speakers: “Why does the greased needle float on the surface of a tumbler of water and the wetted needle sink?” Did one or another of the experts present rise […]

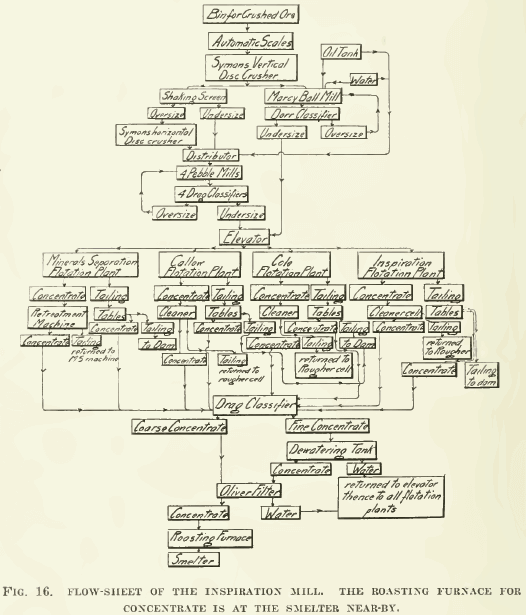

Flotation of Arizona Copper Ore

For some time past the company has been experimenting with a view to finding the best method of concentrating the sulphide ore before smelting. The first test-mill consisted of two sets of rolls, one Chilean mill, one Hardinge conical mill 6 ft. diam. by 12 in. cylinder, Richards hindered-settling classifier, Deister tables, some kind of […]