Grind Size & Liberation for Optimum Flotation Recovery

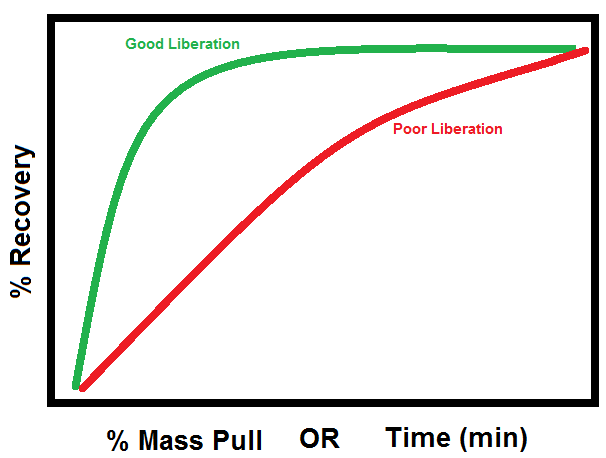

Here is a trick for knowing if your flotation feed grind size is fine enough to achieve adequate mineral liberation without doing a full mineralogy study. If your key mineral is sufficiently liberated, it should float and be recovered in the first few minutes in an initial %mass that stabilizes quickly = the green curve. […]

Flotation Circuits Diagrams

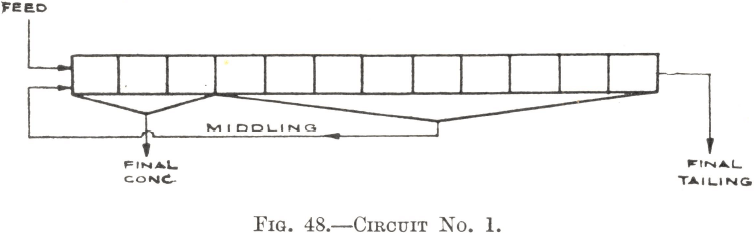

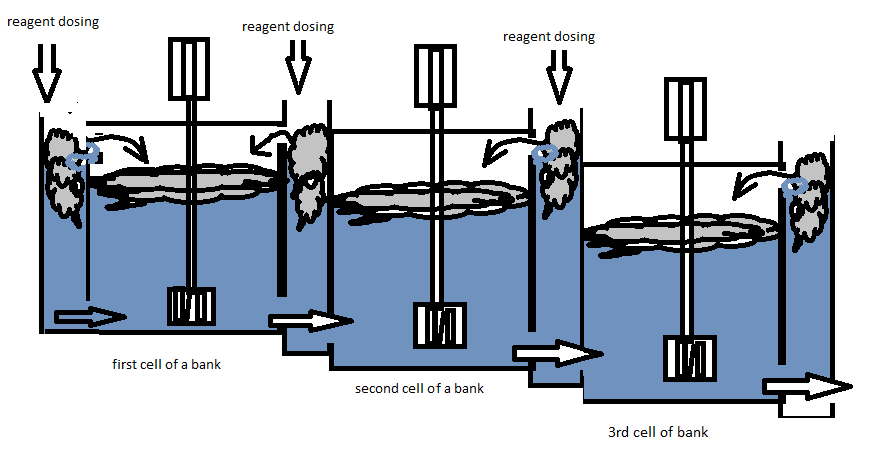

Since several types of flotation circuits can generally be employed in conjunction with the various processes for the flotation of different classes of minerals, an outline of the standard circuits in common use is best given before the processes to which they are applicable are described. The flow sheets illustrating them are diagrammatic, but, in […]

Silver Gold Recovery Flotation Process

The ores from which silver and gold are recoverable by flotation divide themselves naturally into two general processing classes: ores in which the valuable minerals are those of the base metals, the precious metals being incidental constituents, and ores in which the gold and silver are of primary importance, the base-metal minerals, if present, being […]

Compare Flotation Machines Types

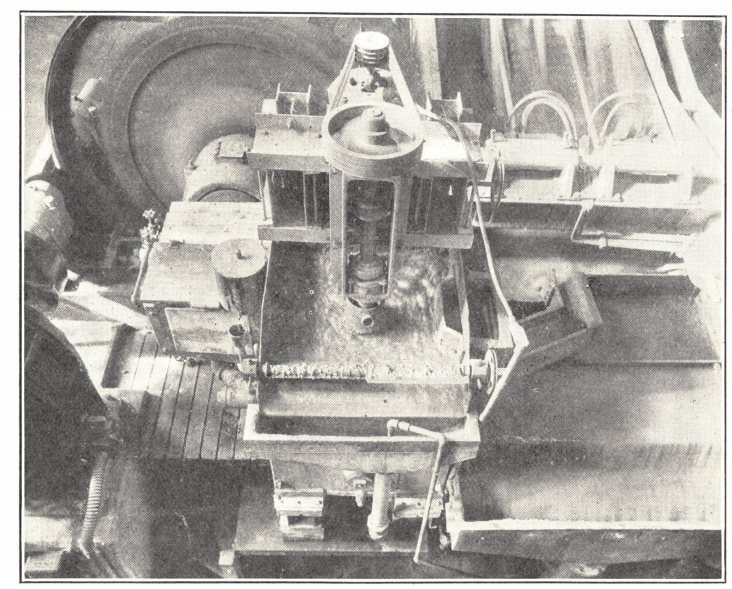

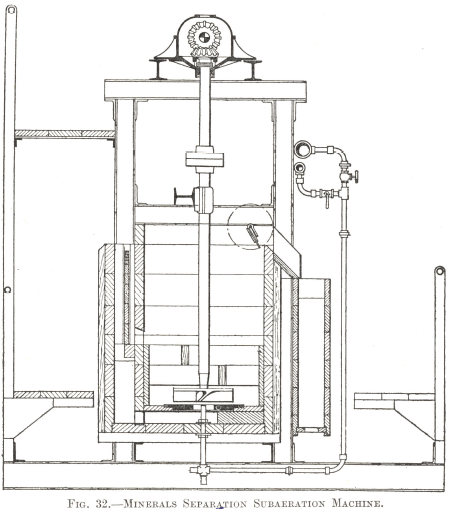

In the 1950s, the opinion was often expressed that the mechanically-agitated machine forms the best rougher and a pneumatic machine the best cleaner, the reason being that the former type has come to be regarded as one that yields a heavily-mineralized froth, which, though giving a good recovery of the minerals, is likely to be […]

Flotation Conditioning

Flotation Conditioning is often necessary as it is not sufficient merely to make the addition of the various reagents to the pulp and then to proceed with flotation. Intimate admixture is essential in order not only to bring about their even dissemination throughout the pulp but also to ensure that the millions of particles of […]

Surface Tension & Contact Angle Flotation Bubble

Surface-Energy of Liquids and Surface-Tension The attractive forces mutually exerted between the interior molecules of a liquid produce at its surface the energy effects known as its “ surface-tension Within the mass of the liquid, each molecule attracts and is attracted by its neighbours with a force as intense as it is limited in range […]

Laboratory Flotation Test Procedure

Mineralogy & Flotation: Floatability VS Selectivity Test Assessment Flotation Kinetics: Mass & Water Recovery VS Entrainment & Mineralogy Timed Flotation Test: Concentrate Collection & Cumulative Grade Recovery Curve

Flotation Simulation Model

Flotation Kinetics Calculator

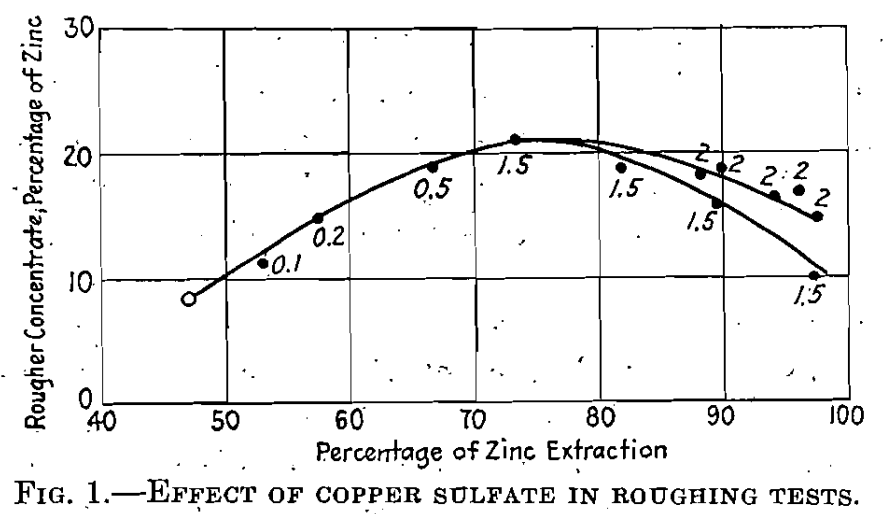

Effect of Copper Sulfate on Zinc Sphalerite Flotation

As an example of the beneficial effect of copper sulfate in the activation of zinc sphalerite toward flotation, the series of results shown in Fig. 1 is of interest. These represent rougher tests on a sample of heavy pyritic ore. The particular sample in question contained about 5.6% zinc as marmatite; and was treated in a circuit […]