Copper Nickel Flotation

The Bureau of Mines investigated the flotation responses of two copper nickel ore samples from the Duluth Complex with the objective of recovering bulk sulfide concentrates. One of the ores studied was taken from a test pit; the other was taken from a test shaft. The samples were quite similar except that the pit sample […]

Flotation of Chromite Ore

The Stillwater Complex in Montana (mainly the Benbow and Mouat deposits) contains an estimated 15.7 million short tons of ore containing 1.3 million short tons of recoverable chromium. This represents approximately 75 percent of available domestic chromite and could supply U.S. needs for about 4 to 5 years, but it is low in grade and […]

Fluorocarbon & Hydrocarbon Collectors

Quartz did not float significantly at any pH value between pH2 and pH12 when any of the anionic collectors were used. The flotation of alumina with anionic collectors is depicted in figure 1. It can be seen that SOL functions as a good collector for alumina over most of the pH range studied, the recovery […]

Increase Uranium Recovery by Nitric Acid Leaching

To meet these uranium demands, larger, lower grade, and refractory ore bodies will need to be exploited. The utilization of these ores will require the development of new and improved processing technology. In its program of Advancing Minerals Technology, the Bureau of Mines is investigating innovative methods for recovering minerals and metals from low-grade and […]

COARSE FLOTATION

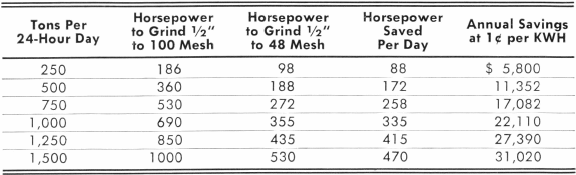

COARSE FLOTATION OFFERS IMPORTANT SAVINGS THROUGH REDUCED OPERATING COSTS Grinding cost varies greatly depending upon the size reduction required. For example, it takes approximately 50% less horsepower to grind from ½” to 48 mesh than it does to grind the same material from ½” to 100 mesh. Many minerals are liberated at a coarse mesh […]

COAL FLOTATION

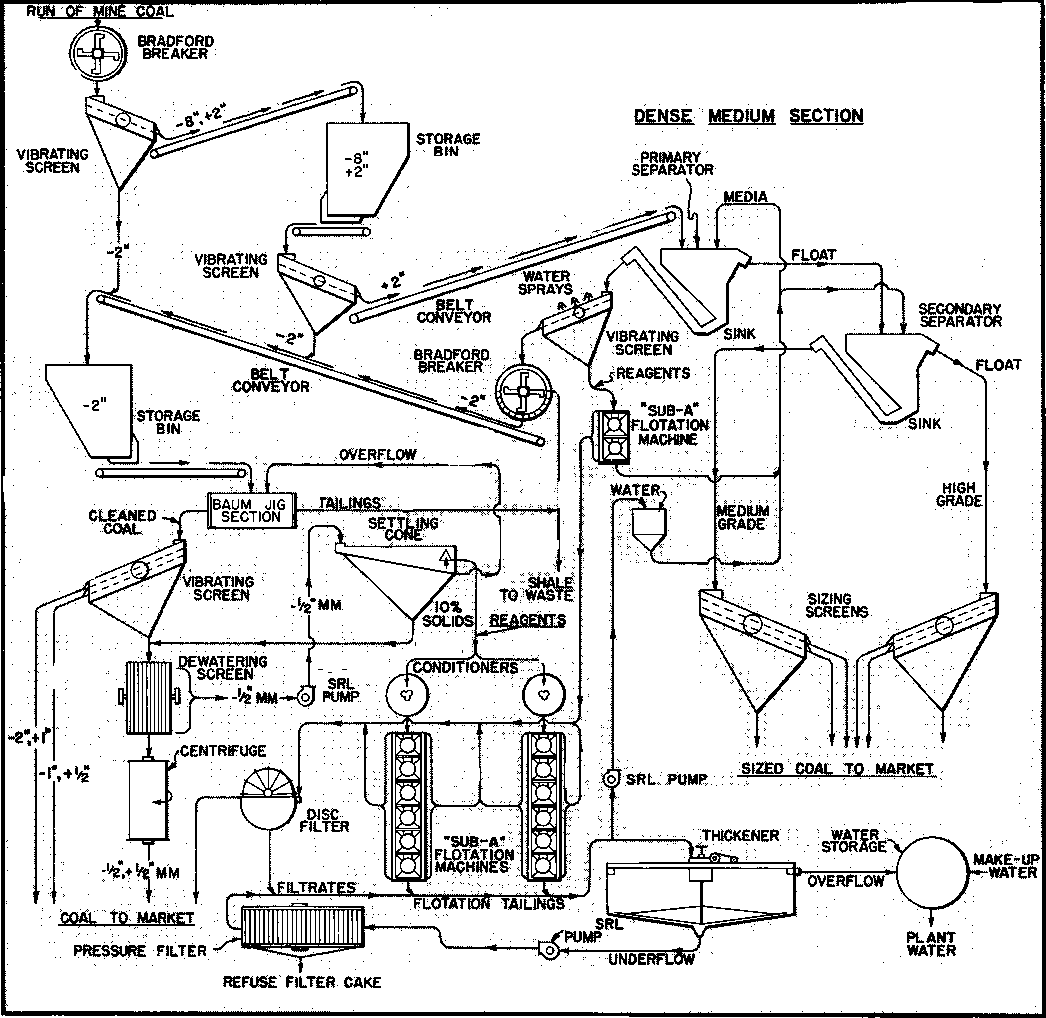

The flowsheet in this study illustrates the general practice in the United Kingdom. A large number of coal preparation plants have been established by the National Coal Board during the past 10 years. The primary consideration is to achieve a maximum recovery of low ash coal. The secondary consideration is to reclaim the plant water […]

Particle Size Range Amenable to Flotation

SILVER LEAD ZINC FLOTATION

The recovery of silver minerals occurring in a lead- zinc sulfide ore is efficiently accomplished using the above flowsheet. The process consists of selective flotation to produce a mixed silver-lead concentrate for maximum smelter return and a separate zinc concentrate. Over-grinding of silver minerals is detrimental to efficient flotation recovery, so the Unit Cell is […]

Dodecyl Mercaptan Collector for Sulfide Ores

An analysis of a commercial flotation operation cannot be undertaken without considering the effectiveness and characteristics of the mineral collector. While many operations show satisfactory metallurgical performance, others are characterized by low recoveries of certain metals. Factors such as inadequate liberation, surface oxidation of sulfide minerals, or the adverse or depressing action of some modifying […]

Copper Ore Crushing, Grinding & Flotation

Crushing and Grinding You will note that the Oracle Ridge project has utilized a two-stage crushing circuit with a double acting jaw crusher and cone crusher. In order to utilize this system, the jaw crusher is oversized to produce all -5 material for the cone mill with a screen in closed circuit. Normally a three-stage […]