Process for Recovering Chromium Scrap

Described here is a process for recovering chromium and other metals from superalloy scrap. Laboratory-scale experiments were conducted to test a complex flowsheet utilizing a wide range of extractive metallurgical operations. The novel basis for the process is the formation of a sulfide matte in which chromium is concentrated in a discrete chromium sulfide phase. […]

Molybdenite Flotation

Factors Directly Affecting Molybdenite Flotation: The average molybdenite recovery in the copper concentrator for the first nine months of 1980 was 67.13%. In recent months, there has been approximately an 80% recovery of the molybdenite in the sand and slime rougher floats. The losses in the sand float are due mainly to fine molybdenite particles locked […]

Carnallite & Sylvinite Ore – Potash Flotation

The mission of the Bureau of Mines minerals research program is to help improve minerals processing technology so that the Nation’s mineral needs can be fulfilled in a manner that reduces waste and ensures that minerals and metals are processed, used, and recycled at acceptable economic, social, and environmental costs. In accordance with this mission, […]

Microbubble Flotation Column

The Microcel™ sparger consists of in-line static mixers and a centrifugal pump. Tailings slurry is pumped from the base of the column through the static mixers, where air and slurry are mixed under high-shear conditions to create the bubble dispersion. As the air-slurry mixture passes through the stationary blades located inside the mixer, the air is sheared into very small bubbles by the […]

Chromite Flotation

Careful studies of the fundamentals of chromite flotation have been made recently in the United States and in Poland. Palmer (1972), Palmer, Fuerstenau and Aplan (1975) and Fuerstenau and Palmer (1976) have demonstrated the importance of the presence or absence of charged metal hydroxy species in such flotation. These species appear particularly to influence anionic […]

Zinc Regrind

The flotation section starts with a bulk concentrate float for lead and copper using four rows of eleven cells each as roughers and scavengers. The froth taken off the roughers is then pumped to a two stage cleaner circuit. Scavenger froth and cleaner tails are returned back to the head of the rougher circuit. Froth […]

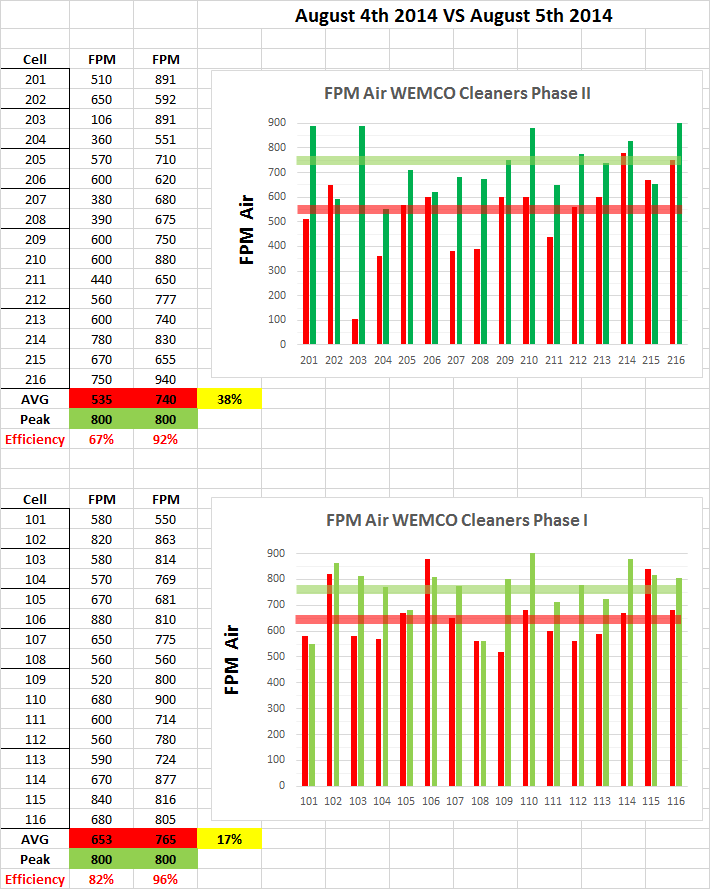

Anemometer to Measure Air Flow Self Aspirating Cell

I once used an Anemometer to Measure Flotation Cell Air Flow on Self Aspirating WEMCO machines. Overtime, operations & maintenance got lazy and never took care of cleaning the airflow supply pipe into the cell. It was clear flows were partially to completely blocked. I improvised the method and now found one the US Bureau […]

Selective Flocculation and Flotation

The Bureau of Mines undertook a research program to insure an adequate supply of iron raw materials for future iron and steel making needs. A sample was obtained of oxidized taconite from the western Mesabi Range in Minnesota, and the metallurgical response of the taconite to beneficiation by a process that included selective flocculation-desliming-cationic flotation […]

Recovery of Rutile Titanium Dioxide

The increasing demand for titanium minerals, especially rutile, has sparked interest in the abundant domestic titanium resources of the United States. Although 93 percent of the rutile used in this country is imported, there are porphyry copper deposits in the Western United States that constitute a very large potential rutile resource. Rutile is used to […]

Platinum – Palladium Flotation

An exploration program initiated by Johns-Manville Corp. resulted in the discovery of significant occurrences of platinum-group elements in the Stillwater complex of south-central Montana. The mineralization occurs in a horizon of relatively sulfide-rich anorthositic rocks within the Banded Zone of the complex. The favorable horizon is continuous over a strike length of 24 miles. The […]