Optimising Mixing in Anionic Conditioning Phosphates

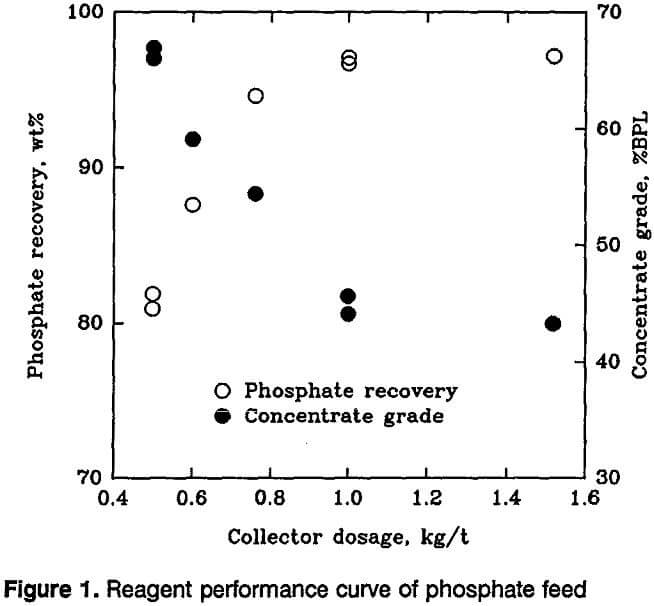

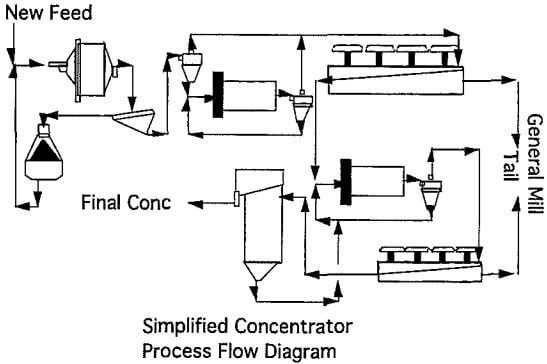

The process design emphasizes maximum recovery of phosphates in the anionic flotation stage to eliminate further processing of the underflow. The flotation performance of phosphate ore in the anionic flotation stage is determined to a large extent by anionic conditioning, the unit operation prior to flotation where the reagents (collector) and phosphate slurry are mixed […]

Integrating Plant Wide Control of Supervisory Expert System

Opportunities for maximizing corporate revenues through plant-wide process control strategies are being sought in virtually all industries. The mining industry, in particular, can realize tremendous benefits through implementation of systems that simultaneously monitor, model and optimize unit processes and their interactions. The tendency to downsize the corporate structure, improve productivity while decreasing manpower, and increase […]

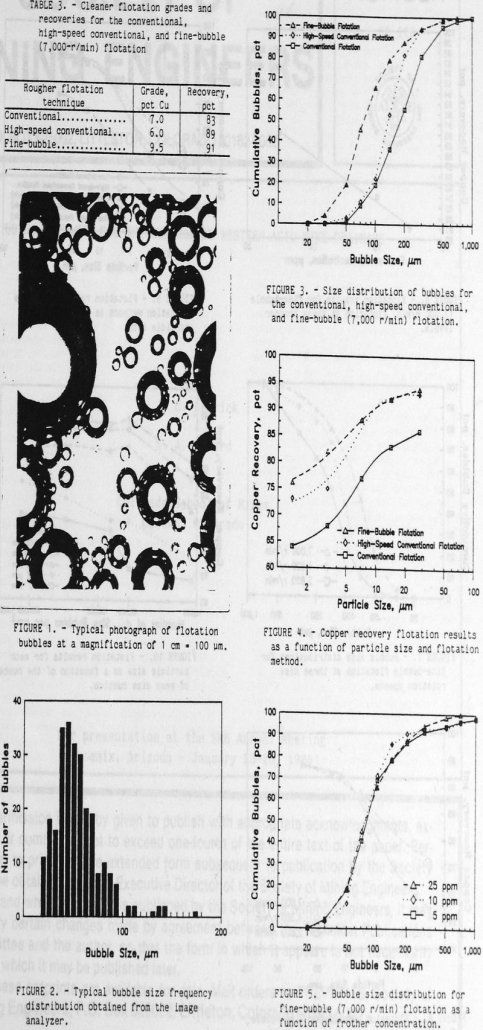

Air Sparged Hydrocyclone Flotation & Bubble Generation

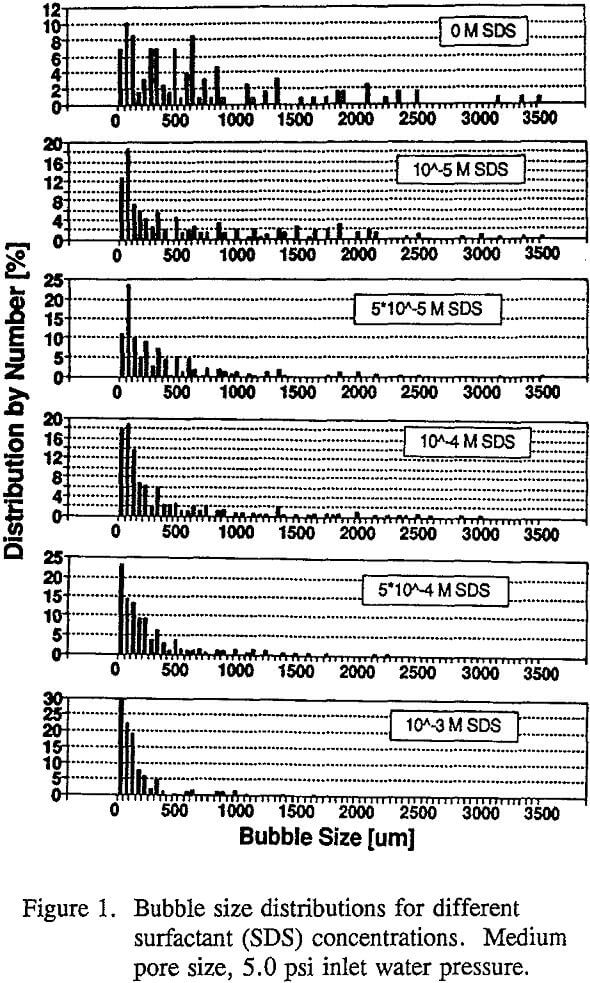

Air-sparged hydrocyclone (ASH) flotation is one of the new promising technologies. Numerous applications have been successfully tested since its conception; nevertheless, research and development efforts have continued to provide for further improvements with respect to operating conditions and design considerations. Bubble size is always of interest in the analysis of flotation separations. Many researchers believe […]

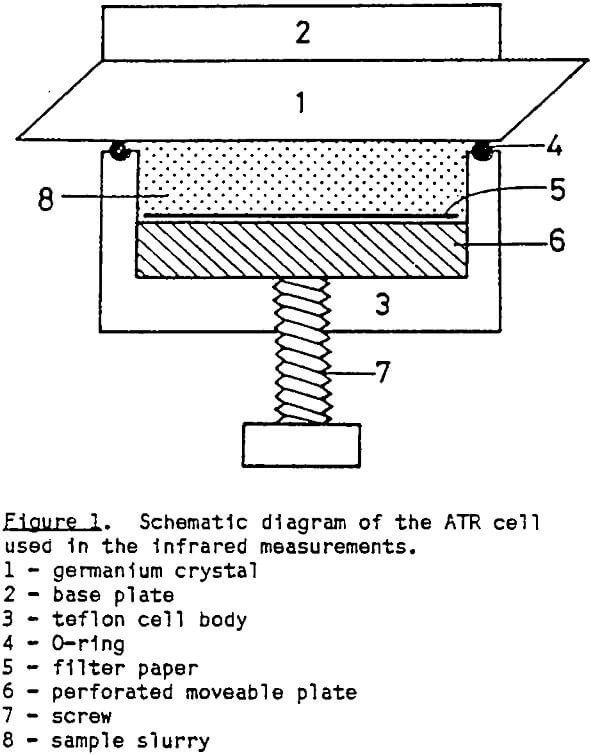

Flotation Bubble Contact Angle Measurement Method

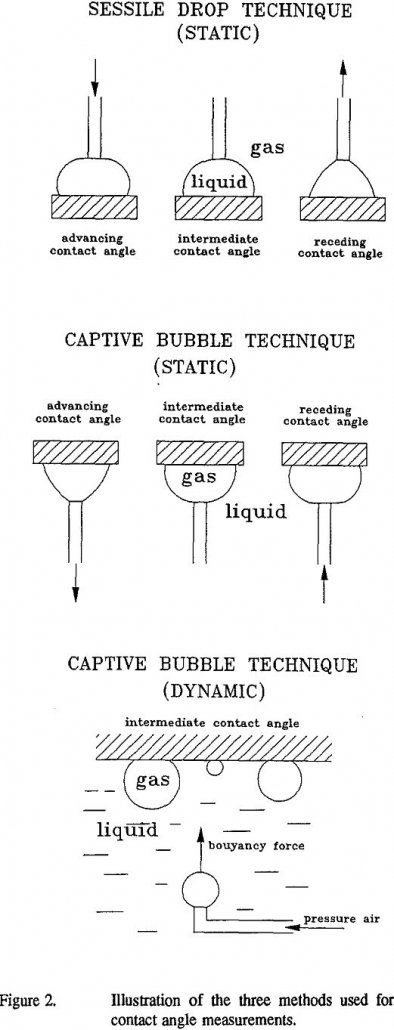

Among the wide variety of modern surface chemistry analytical techniques, contact angle measurements still remain attractive for wetting characterization of solid surfaces. It is demonstrated that the contact angle value depends on the technique used when nonideal, heterogeneous and rough, solid surfaces are examined. Reagents and Materials Three different solid surfaces were used in the […]

How to Improved Fine Particle & Bubble Flotation

Selective beneficiation of fine particles depends heavily upon the flotation separation process. Conventional froth flotation for many ore systems is very effective for particles between 300 and 20 µm in size, but the flotation efficiency commonly drops off as the particle size decreases below 20 µm. Flotation kinetics has been used by Sutherland (1955) and […]

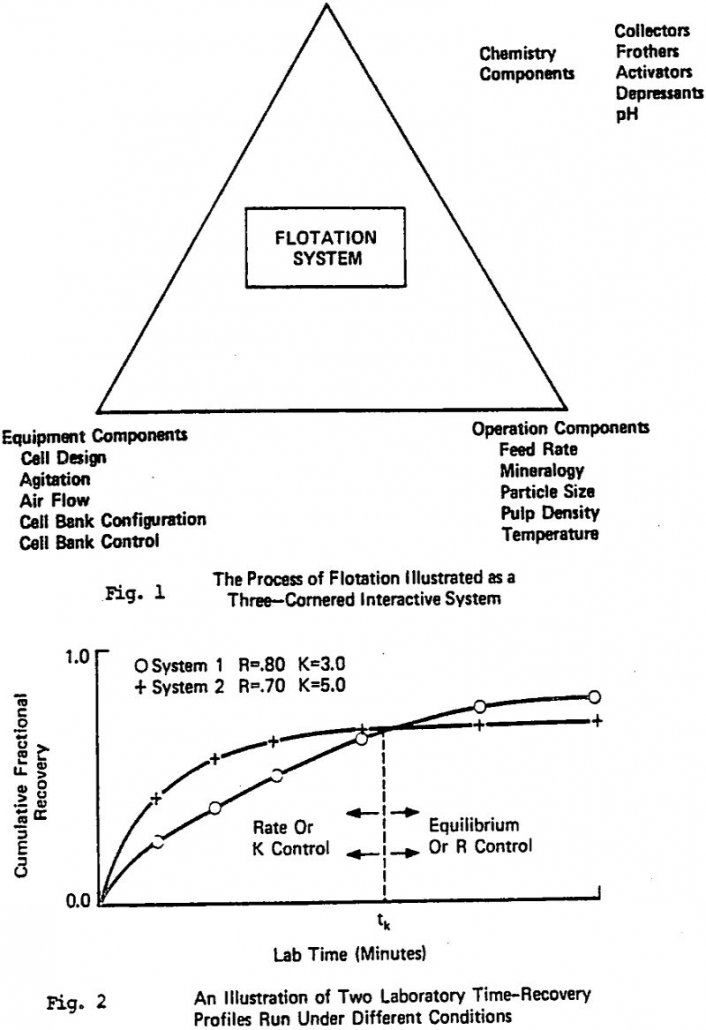

Methods of Improving Mineral Flotation Circuit Performance

The process of froth flotation as a means of upgrading the quality of coal by removing ash/pyrite and of separating selected mineral(s) from undesired gangue materials is certainly one of the most common unit engineering operations in use today. Flotation has been successfully practiced at the industrial scale for well over 50 years, and if […]

Thionocarbamates Collector & Sulfide Flotation & Adsorption

The mineral processing industry has recently shown an interest in developing new collectors that can be used for selective flotation at lower pH levels. The desired end result is to reduce lime consumption and to improve the efficiency of separation in the treatment of complex and low-grade ores (Nagaraj et al., 1986c). One such reagent, […]

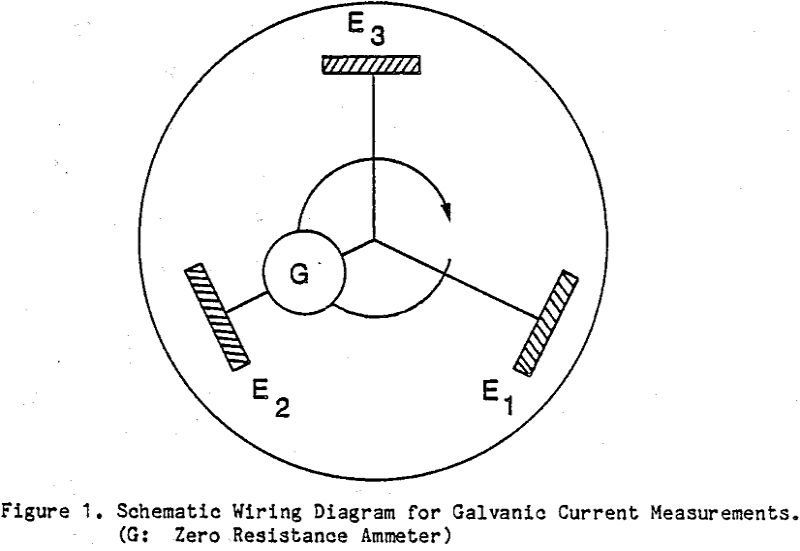

Effect of Grinding Media on Flotation Chemistry

The flotation behaviors of pyrite and pyrrhotite in a Hallimond tube were correlated with the galvanic role they developed in two- and three-electrode combinations with mild steel under non-abrasive conditions. These correlations substantiated the hypothesis that a coating of iron hydroxides, originating from galvanic interactions, lowered the flotation responses of sulfide minerals. However, interactions between […]

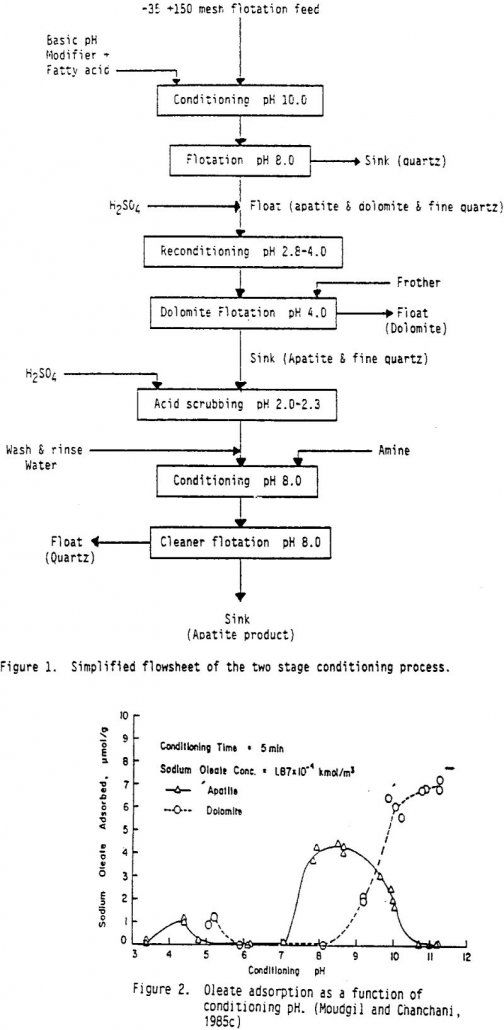

MgO Dolomite Flotation

A selective dolomite flotation process has recently been developed at the University of Florida whereby a two stage conditioning technique is utilized to remove MgO impurities. Previous investigations have mainly involved studies on synthetic apatite/dolomite mixtures in a microflotation (Hallimond) cell. The collectors employed were of laboratory reagent grade and flotation was carried out in […]

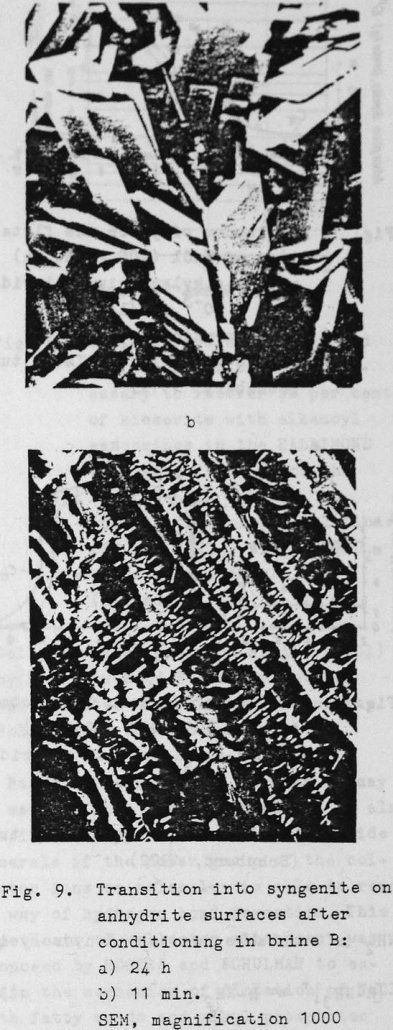

Sylvite & Halite Flotation – Salt Mineral Collectors

The flotation of sylvite (KCl) and also some accessory minerals (e.g. kieserite, langbeinite) from crude potash salts are processes used to a large extent all over the world. These separations are made in brines which are in an approximate solubility equilibrium with the mineral phases of the crude potash salts and thus contain concentrations of […]