Coal Wettability & Floatability

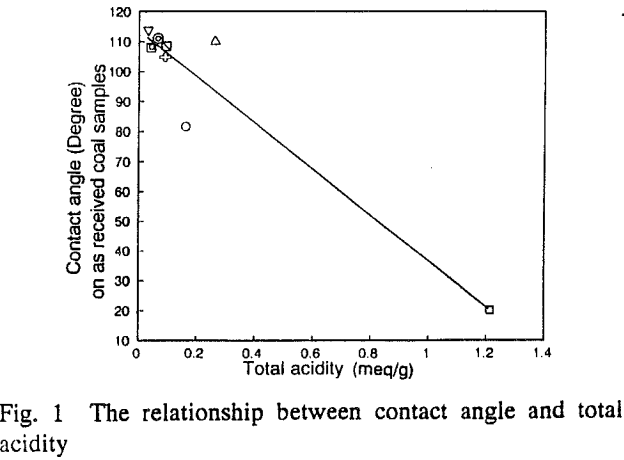

In testing and designing coal flotation circuits, there are still a lot of unanswered questions. It is still not clear whether it is better to work with the use of flotation feed obtained from a plant and then to cope with all types of sample storage problems, or to rely on a coarse coal sample […]

Surface Charge in Flotation

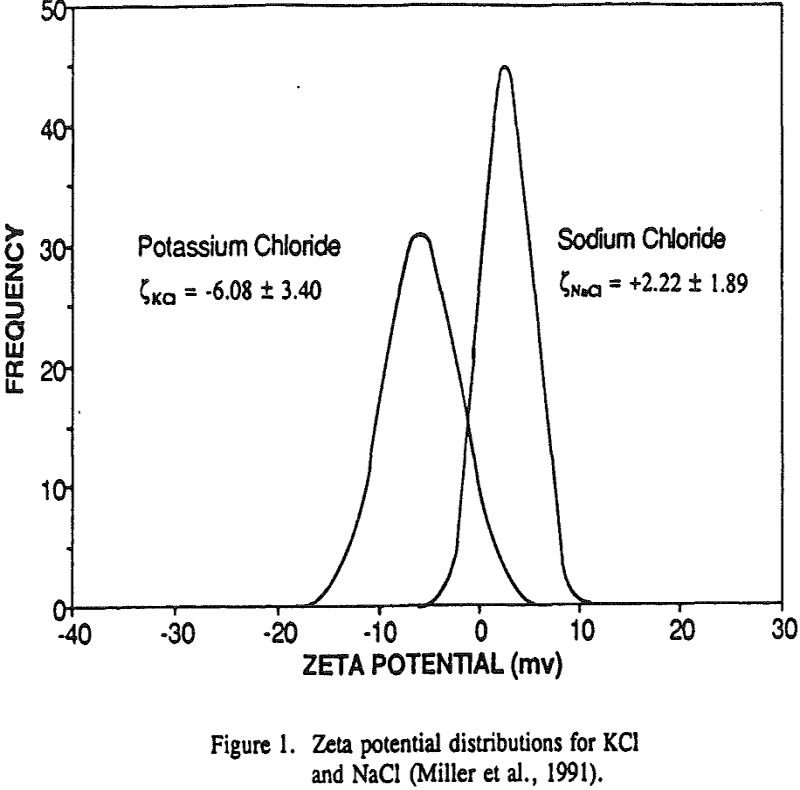

The selective flotation of alkali halide salts such as KCl and NaCl is of great industrial significance and has been considered by flotation chemists for many decades. The surface-charge model was rather controversial when it was first presented at the SME Annual Meeting in Los Angeles in 1967. Basically this model suggested that the alkali […]

Bench Scale Froth Flotation & Economic Estimate

ICF KE assembled a team that included members of industry, academia, and industry research organizations to conduct this multi-task program. The original design was based on a philosophy developed by the members that incorporates the DOE contract requirements and desires for future commercialization. The following is a listing of the design philosophy: Minimum acceptable energy […]

Pyrite Recovery Mechanisms in Coal Flotation

In many coal flotation operations, a significant amount of apparently liberated pyrite is seen to report to the froth, thus raising the sulfur content of the clean product and reducing its economic value. Prevention of this unwanted recovery of pyrite is therefore desirable. Theoretical Discussion It has long been known that mineral pyrite has some […]

Extender Oils for Flotation of Coarse Potash

In order to float coarse sylvite particles, Potash Corporation of Saskatchewan Inc. (PCS) uses amines and extender oil. Since the content of polycyclic aromatic (PCA) compounds in Esso 904 oil is high, PCS has sought a suitable replacement. Various types of physicochemical tests, including measurements of the electrokinetic potential of emulsified oil droplets, oil/water interfacial […]

Flotation Frother vs Collector Interactions

In the froth flotation process, different types of surfactants are used to carry out specific and well defined functions. For example, an anionic surfactant such as xanthate is added as a collector in the flotation of sulphide minerals and adsorbs at the mineral/aqueous solution interface causing an hydrophobization effect. In addition, non-ionic surfactants are added […]

Fluorspar Beneficiation by Packed Column Flotation

Acid-grade fluorspar is utilized in the production of hydrofluoric acid from which a variety of organic and inorganic fluoride chemicals are made, including synthetic cryolite and elemental fluorine. The manufacture of chlorofluorocarbons (CFCs) is the volume leader in the fluorine chemical industry. Price and market specifications for fluorspar depend on supply and demand, and often […]

Coal Cleaning Technology

The National Energy Strategy (NES) and the Clean Air Act Amendments (CAA) of 1990 are examples of the nation’s commitment to a clean environment. The need to utilize our energy resources in an environmentally sound manner presents critical challenges and opportunities for coal preparation during the next decade, particularly regarding the control of SO2 emissions. […]

How is Pyrite Pyrrhotite Floatabilitt Affected by Contact

Galvanic contact, occurring between electrically conducting minerals in flotation pulps, may affect the nature of mineral surfaces and influence their floatabilities. Rest potential and galvanic current measurements were made on an electrode combination of pyrite and pyrrhotite under nitrogen, air and oxygen aeration conditions, and the results were correlated with their oxygen-consuming characteristics and flotation […]

Role of Sodium Sulfide – Copper Lead & Zinc Ore Flotation

Sodium sulfide is one of the most widely used alkali metal sulfides in the flotation of copper, lead, and zinc minerals in their oxidized form. The sulfidization process, developed in the U.S.A. in 1915-20 for oxide copper minerals flotation, is especially suitable for oxidized lead ores in which the gangue is usually basic. The early […]