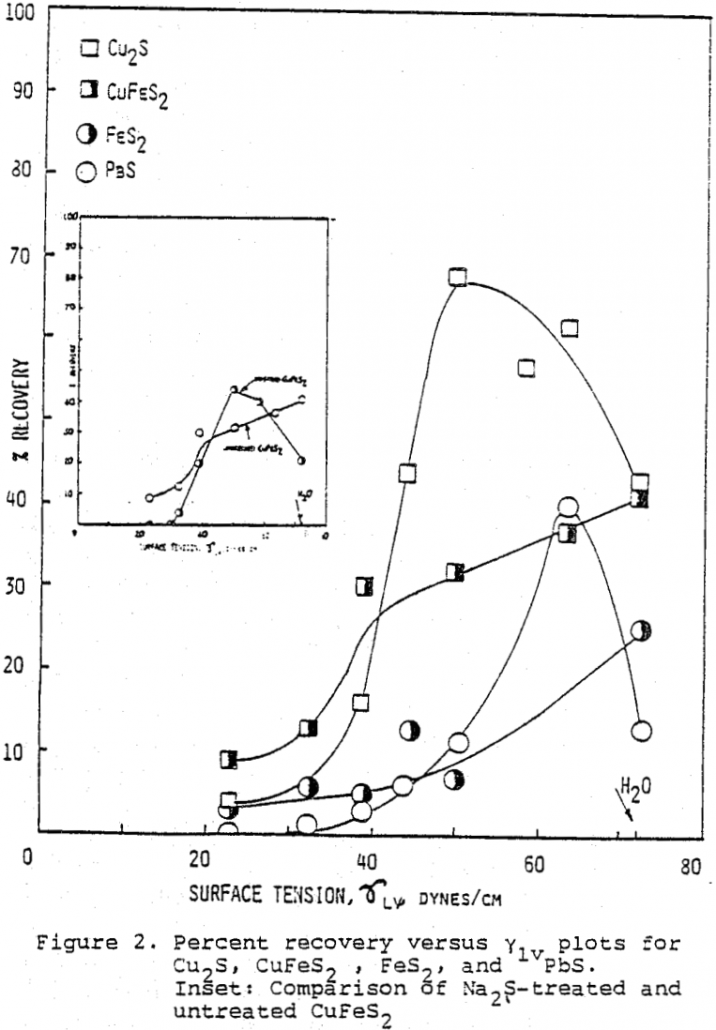

Critical Surface Tension of Wetting of Sulfide Minerals

The critical surface tension of wetting (vc) of Cu2S, FeS2, PbS, and M0S2 were determined by plotting flotation recovery versus γLV which was arranged by methanol, and extrapolating to % R = 0. γc values ranged from 26 dyne cm-¹ for M0S2 to 49 dyne cm-¹ for PbS and elemental sulfur gave a value of […]

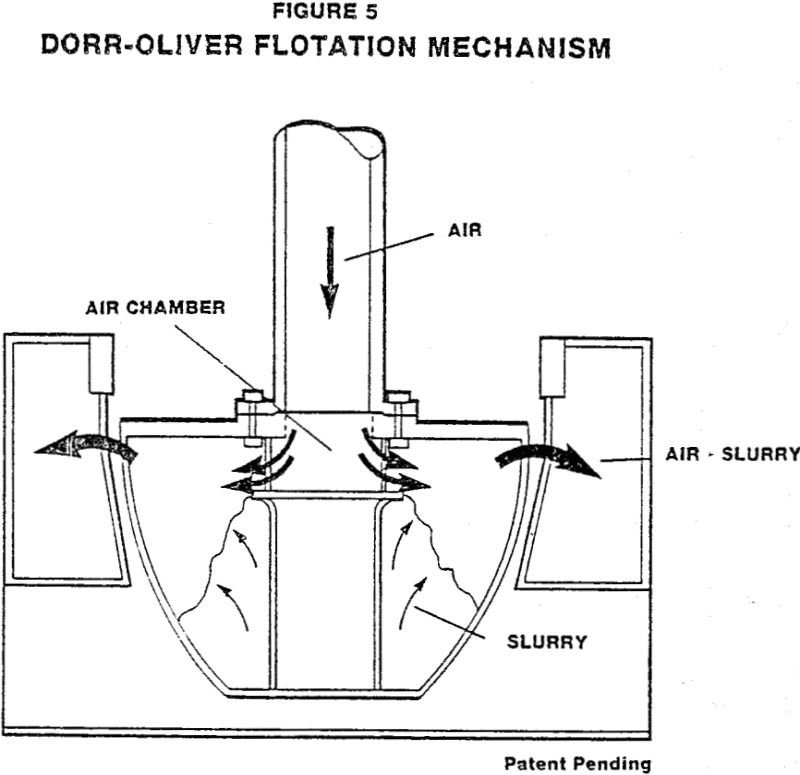

Large Flotation Cell Mechanism

The development of larger size flotation machines, which started in the 1950’s and 1960’s, is still proceeding. The largest mechanical flotation machines available today have unit volumes in the range of 38.2 to 43.9 m³ (1,350 to 1,550 cft). Designs for mechanical flotation .cells of unit volumes as large as 70.8 m³ (2500 cft) are […]

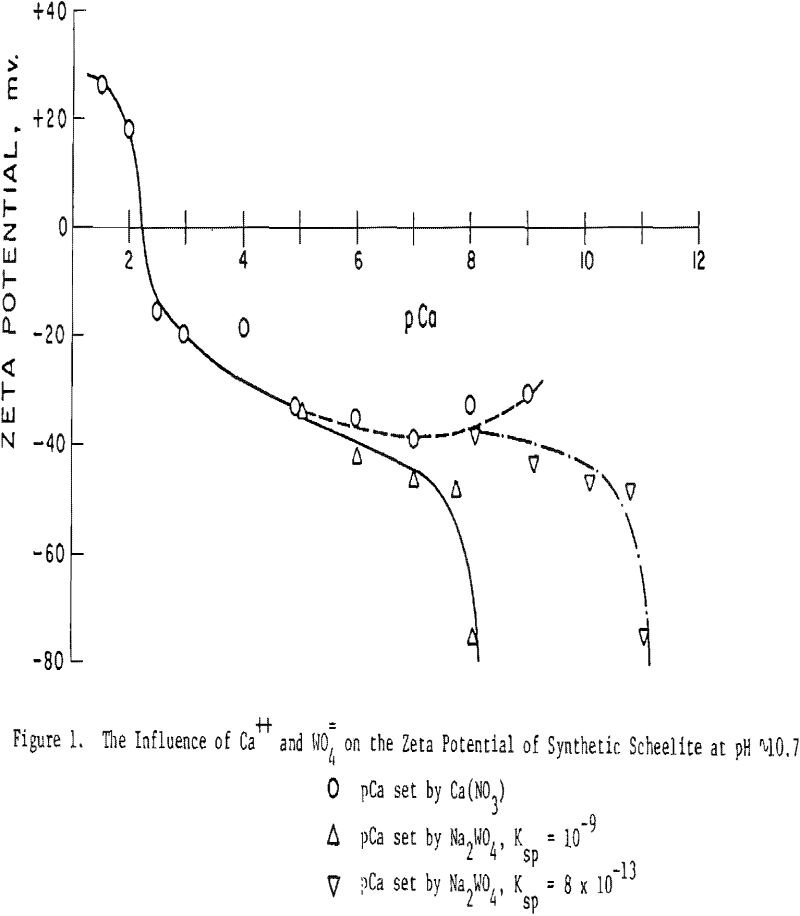

Low Solubility Mineral Flotation

The objective of this study is to evaluate methods to improve the selectivity in flotation of the slightly soluble minerals, typified by calcite, fluorlte and scheelite. The separation of minerals within this class has long been one of the most difficult tasks facing the mineral processing engineer. The slightly soluble mineral class, as defined herein, […]

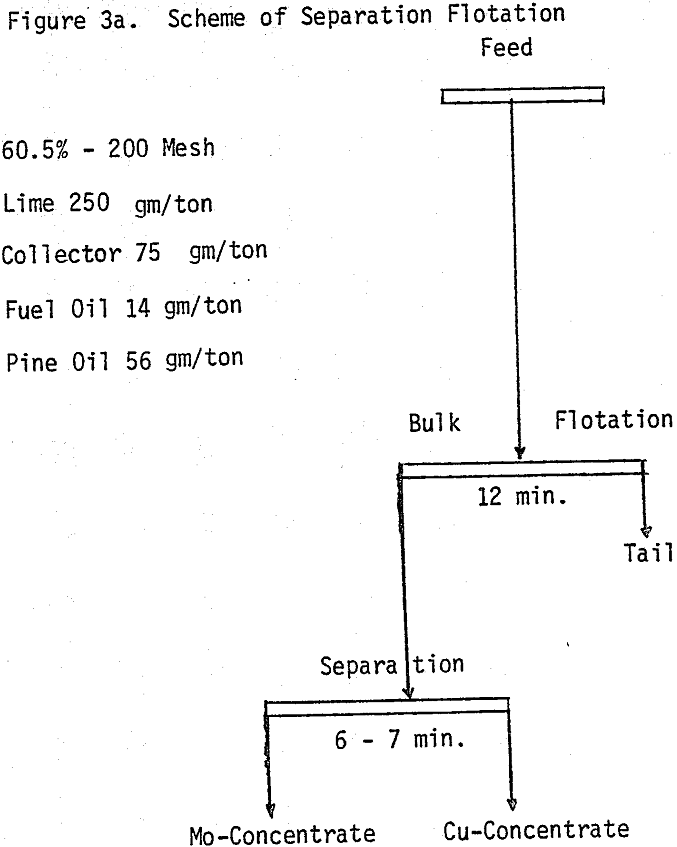

Copper Moly Separation Depressant Roles

Bulk and differential laboratory flotation tests have been carried out using a synthetic mixture of chalcopyrite and molybdenum ore. In addition to boiling and roasting, six different depressants are tested so that the best conditions of separation can be identified. These reagents include sodium cyanide with and without zinc sulfate, potassium ferrocyanide, sodium hydrosulfide, arsenic […]

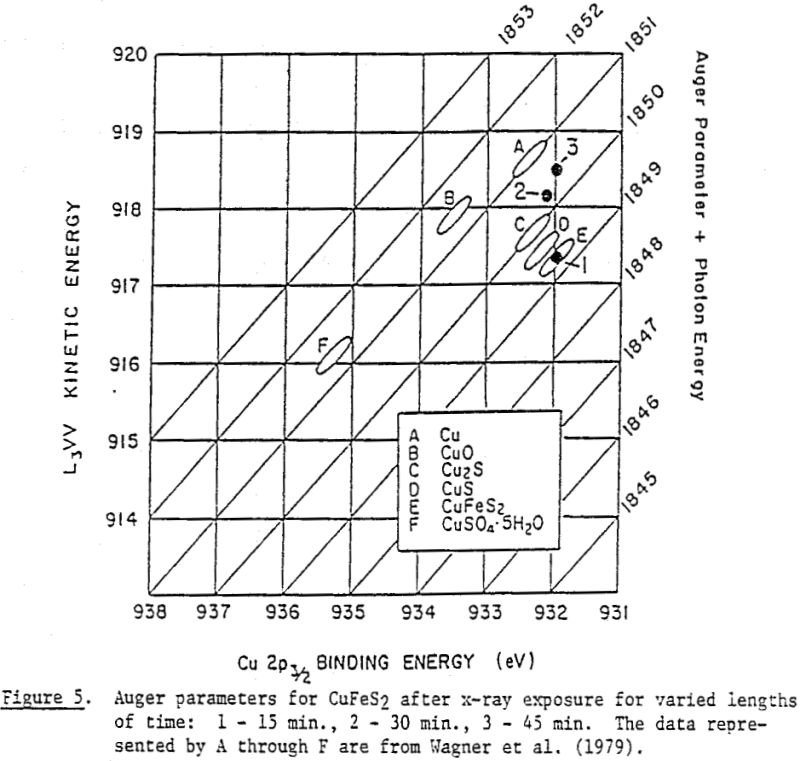

Chalcopyrite Flotation without Collector – Surface Chemistry

It has been reported that chalcopyrite can be floated selectively from an ore containing pyrite, sphalerite, and silicious gangue minerals without using a collector. Sodium sulfide was used as a promoter, presumably to clean the chalcopyrite surface of its hydrophilic oxidation products. Later it was found that the potential of the pulp, measured with a […]

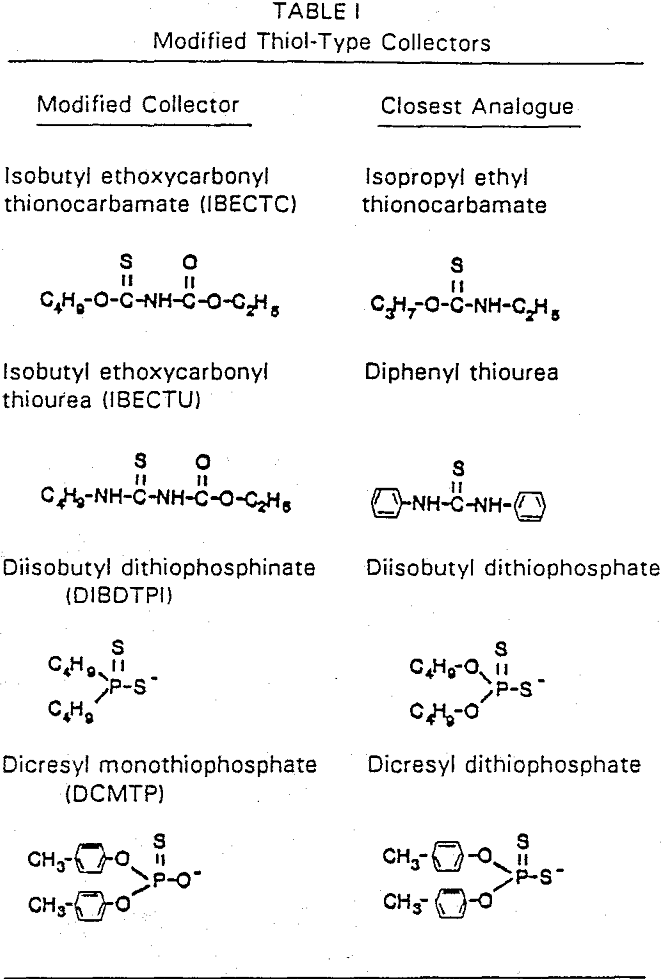

Thiol Type Collectors Adsorption Mechanisms

The formation of metal xanthate can be considered to comprise an initial electrochemical reaction (E), MS → Mn+ + nS° + ne……………………………………………………………[1] followed by a chemical reaction (C), Mn+ + nX- → MXn………………………………………………………………..[2] Thus, the xanthate adsorption mechanism is controlled by both Eh and pK, and consequently, one can expect that the same may be applied to […]

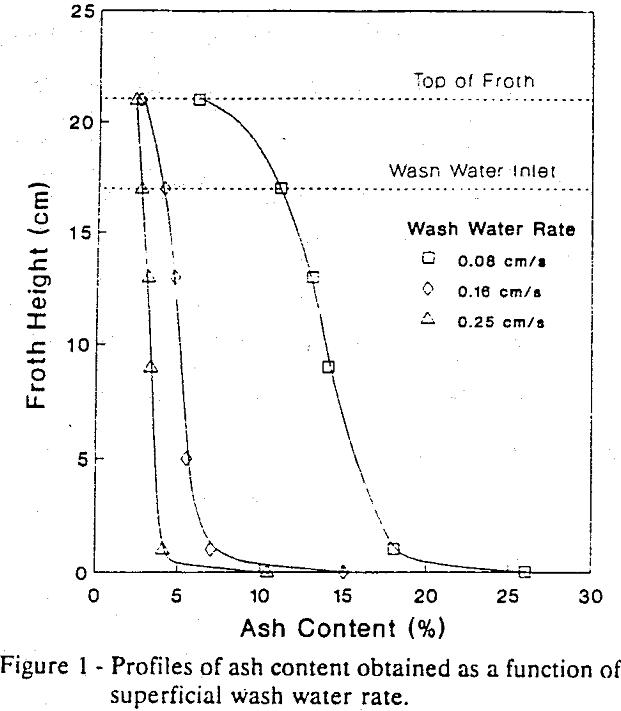

How Froth Affects Column Flotation

The importance of the froth phase in establishing flotation performance has long been recognized. If the froth phase is insufficiently stable, mineralized bubbles which enter the froth layer rupture prematurely, causing valuable particles to drop back into the pulp. On the other hand, too stable a froth may result in nonselective entrainment of excessively large […]

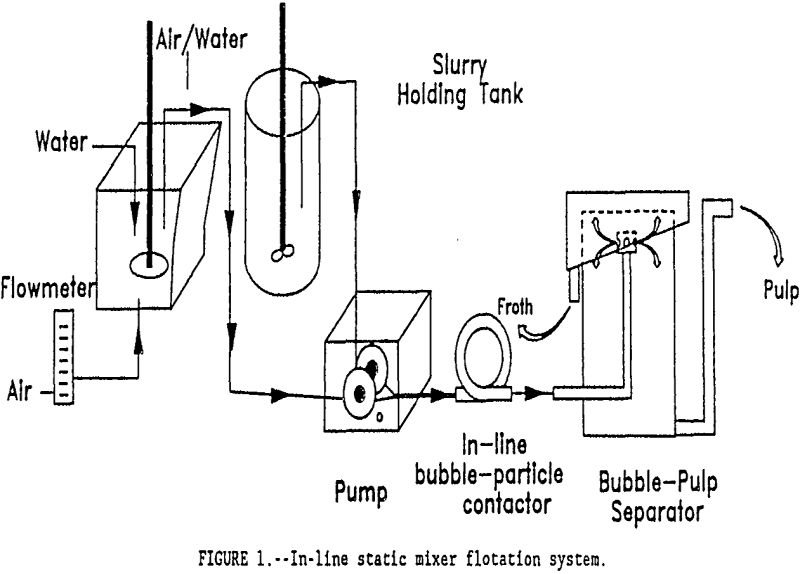

Improve Flotation Kinetics by High Intensity Agitation

Flotation is the most widely used beneficiation technique in the minerals industry. The kinetics of flotation is governed by the rates of bubble-particle attachment and bubble-pulp separation. Both processes interact significantly in a conventional flotation unit operation, making it virtually impossible to optimize one of the processes without sacrificing the effectiveness of the other. In […]

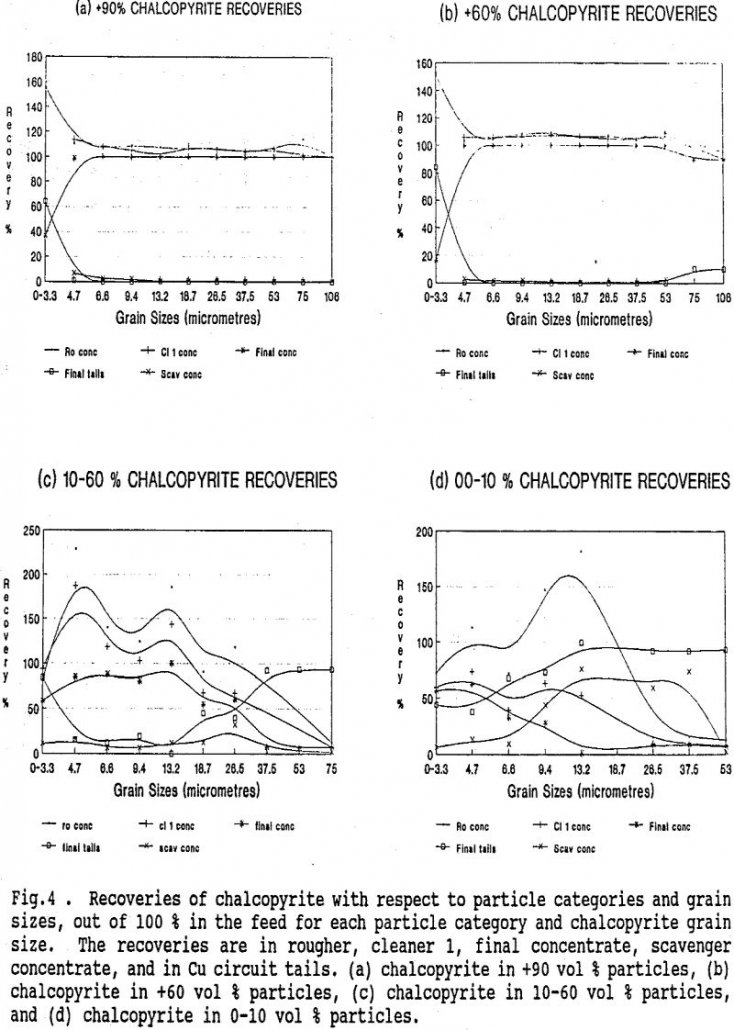

How to Determine Mineral Liberations by Image Analysis

Evaluations of mineral beneficiation circuits and concentrators require information on mineral liberations, on mineral recoveries and on behaviours of liberated and partly liberated mineral grains. A qualitative evaluation of mineral, liberations can be made by examining polished sections of ores with an optical microscope, but the data are not accurate enough to calculate mineral recoveries […]

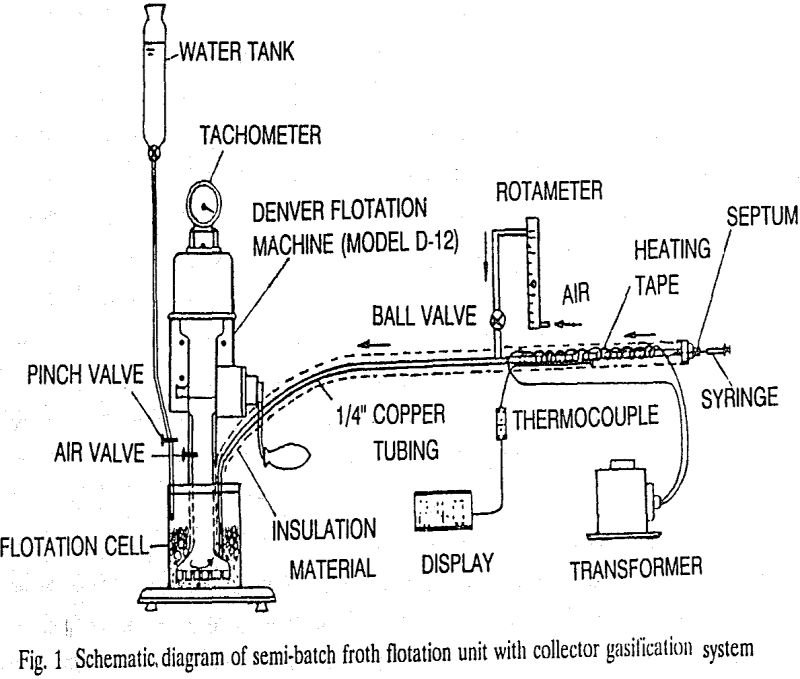

Improve Coal Flotation Rate and Recovery

A unique collector dispersion techniques was developed and used to improve the flotation rate and recovery of coarser and ultrafine coal-rich particles in the froth flotation processes. In this novel collector dispersion method, the collector such as hydrocarbon-oil is gasified and transported by gas phase (air stream) into the pulp. In addition to the excellent […]