Concentrate Dewatering & Thickening

The concentrate from the flotation section usually contains only 20 to 30% of solids as it leaves the cleaning machine and must be dewatered before being sent to the next department. The operation of dewatering is performed in two stages. First, the bulk of the water is removed in a thickener, from which the concentrate […]

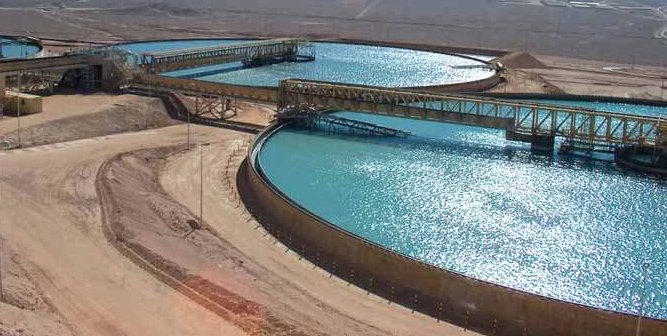

Tailing Disposal Methods and Tailings Dam Construction Design

As there is seldom enough ground available on which the tailing of a flotation plant can be run to waste without being stacked, it is usual to impound it in some form of dam where the solids can be deposited and the water decanted off for return to the plant. It is generally advisable to […]

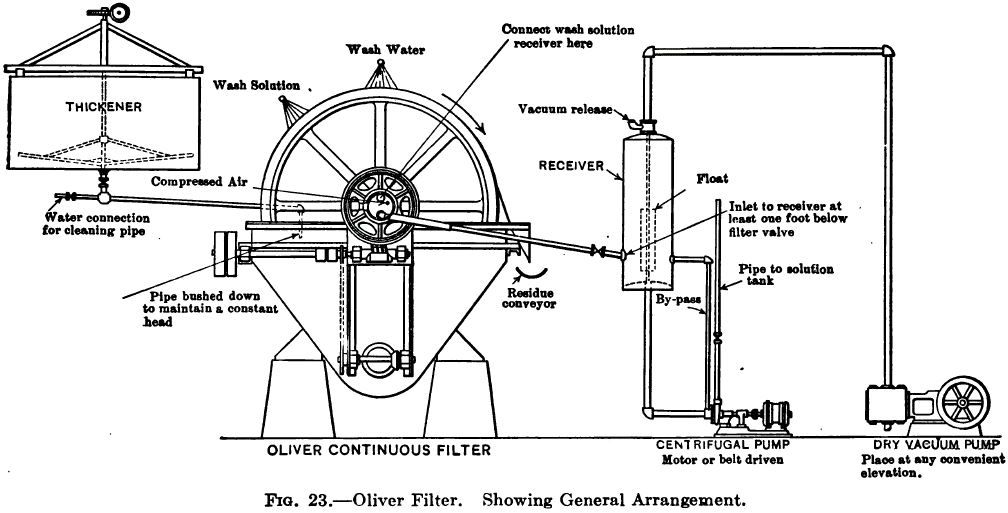

Rotary Drum Filter: Capacity & Installation

The capacity of a vacuum rotary drum filter varies from about 200 to 2,000 lb. of dry concentrate per square foot of filtering surface per 24 hours according to the nature of the material and the amount of water that it contains. For the purposes of rough calculations it is usual to assume a capacity […]

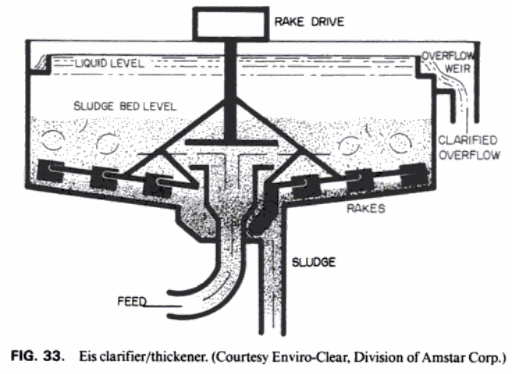

Pulp and Slurry Thickening Test and Calculations

The slime pulp or slurry on leaving the sand classifier with its proper admixture of lime is first led to some form of thickening device if, as is usually the case, the ratio of liquid to solid is too large for economic handling in the cyanide treatment. The form of thickener almost universally used in […]

High Rate Thickeners

There are two basic types of high rate thickener units: Lamina or tube settlers and solids recirculation units Lamina Thickeners They contain space-cutting baffles that intercept settling paths at many levels. Solids settle out onto the baffles and are removed from suspension after settling only a short distance. Where and to the extent that removals […]

CCD Filtration System

Slime treatment, as commonly used by metallurgical engineers, includes thickening, agitation, and filtering and as applied, to cyanidation also includes washing by continuous countercurrent decantation (C.C.D.) and/or filters. “Slime” is the general term used to describe the finer portion of pulp in a combination sand and slime-treatment plant and is usually finer than 100 mesh. […]

Thickener Underflow Pump

The diaphragm Thickener Underflow Pump is essentially one for low lifts and is particularly adapted to handle metallurgical pulps economically and with minimum attention. The Dorrco diaphragm pump was developed primarily as a means of controlling the density of the underflow from the Dorr thickener in the first continuous treatment of cyanide pulps. It has […]

Rotary Disk Filter Flappers

The concentrate is filtered on two 8 by 10 ft. Oliver filters. One of these filters is used for each roaster. The filter cake discharges onto a conveyor belt which feeds the charge directly to the roaster. The concentrate filter cake is at best a sticky, puttylike mass. If the moisture exceeds 20 per cent […]

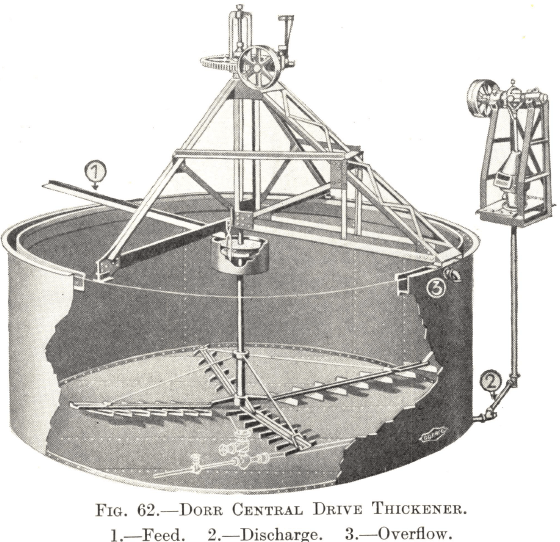

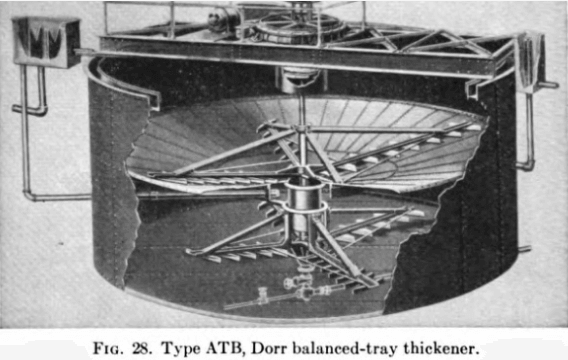

How a Thickener Works

Thickening or dewatering may be defined as the removal of a portion of the liquid from a pulp or slime made up of a mixture of finely divided solids and liquids. The early methods of thickening employed plain, flat-bottomed tanks into which the pulp was fed until the tank was full. The solids were then allowed […]

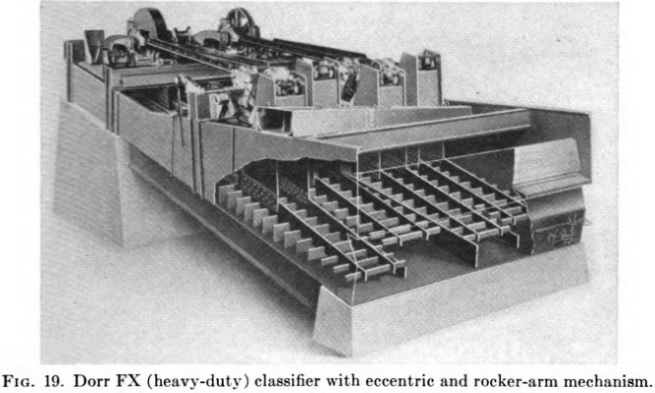

Hydraulic Classifiers

Hydraulic classifiers range from simple V-shaped launders with a multiplicity of shallow settling pockets for the discharge of as many roughly sized products to the more elaborate deep-pocket machines of the hindered- settling type, having specially designed construction plates and automatic discharge of spigot products. Dorrco Sizer In the eight-pocket machine, the pockets are separated […]