Calculating Stockpile Capacity

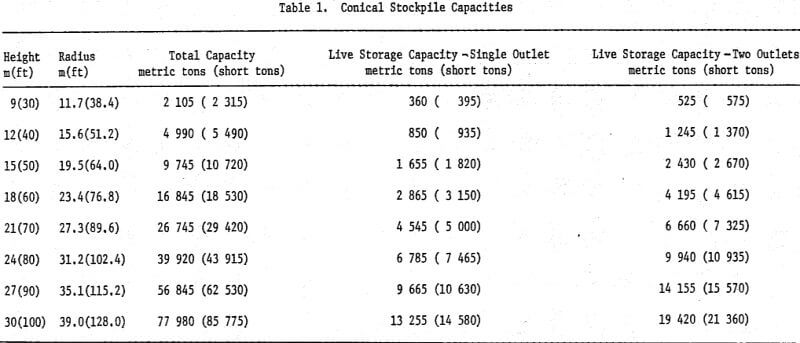

Calculating Stockpile Capacity: Once the minimum storage capacities which will assure maximum mill output are known, the appropriate stockpile configuration must be determined. Stockpiles fall into two general categories: conical and elongated. Conical Stockpiles The conical stockpile is the simplest and easiest to analyze. The total stockpile capacity is given by: 3.14 (Tan A)R³ D/3000 = […]

Belt Conveyors

Belt conveyors are the most commonly used means for building stockpiles. The usual types are the fixed stacker, radial stacker, traveling stacker, shuttle conveyor and tripper conveyor. Fixed Stacker The fixed stacker is an inclined belt conveyor that is normally cantilevered at the head end in order to avoid having conveyor supports in the stockpile […]

Mobile Conveying System Design

The philosophy behind the design and construction of the mobile conveying system is to allow flexibility and rapid movement or “mobility” of conveyors to follow the production face operations on a daily basis. During the conceptual stage, Foster Yeoman engineers were challenged to develop their own unique system to meet the rigid demands that the […]

Belt Conveyor Shifting Equipment

The components of belt conveyor shifting force are a vertical force, Pv, horizontal force, Ph, and longitudinal force, Pl. A method for estimation of these forces is proposed, which relates their value to the properties of the conveyor structure and rails, shifting operation parameters, and other site-specific conditions. Belt Conveyor Shifting In surface mining operations […]

On Line Coarse Particle Size Measurement Analysis

The most serious problem for on-line coarse particle size measurement from a conveyor belt by image analysis is the overlap phenomenon that occurs between adjacent particles. In order to achieve image separation, three methods have been considered for the analysis of projected particle images obtained from overlapped onyx stone and copper ore particle beds of particle […]

Cone Crusher Design

When the Symons brothers invented the cone crusher over 60 years ago, they employed the principle wherein the length of the crushing stroke was related to the free fall of material by gravity. This permitted the material being crushed to fall vertically in the crushing chamber; and in effect caused the particles to be crushed […]

Efficient Crushing in Comminution

Recent research into the mechanisms of crushing processes has led to the establishment of new criteria for the effective design and operation of comminution plants. This paper reviews this work and gives examples of the productivity gains and cost benefits that have been achieved in the practical application of these findings. Large cost reductions have […]

Barmac Crusher Efficiency

Because of the nature of the breakage in the Barmac vertical spindle impactor, the 80% reduction ratio is very small, so that when the energy efficiency is calculated by Bond’s method, it appears to be very low. However, the product size distribution contains a high proportion of fines. It is argued that the production of […]

Mobile Rock Crusher

This Mobile Rock Crusher provides a portable crushing capability to keep conveyor haulage close to the working face and permit more efficient and safer ore handling in low headroom, hardrock mines. A readily portable jaw crusher is used which meets machine size, feed rock size, product size, and throughput requirements for low headroom, hardrock mines. How […]

Foam for Dust Control

The Code of Federal Regulations (Title 30, Chapter 1, Part 57, Section 57.5-1) requires that metal and nonmetal mines shall maintain a time weighted average (TWA) for total and respirable airborne dust concentrations below that established by the American Conference of Governmental Industrial Hygienists in 1973. This TWA for total dust concentrations must be under […]