Dust Collection and Control in Crusher Plant

Crushing plant layout and ventilation system design for the Urad mine was based on our operating experience at similar crushing facilities located at the Climax operations. Low speed conveyors of generous width, adequate exhaust volumes at all ore transfer locations, large hoods and good conveyor skirting have made the Urad underground crusher dust control operations […]

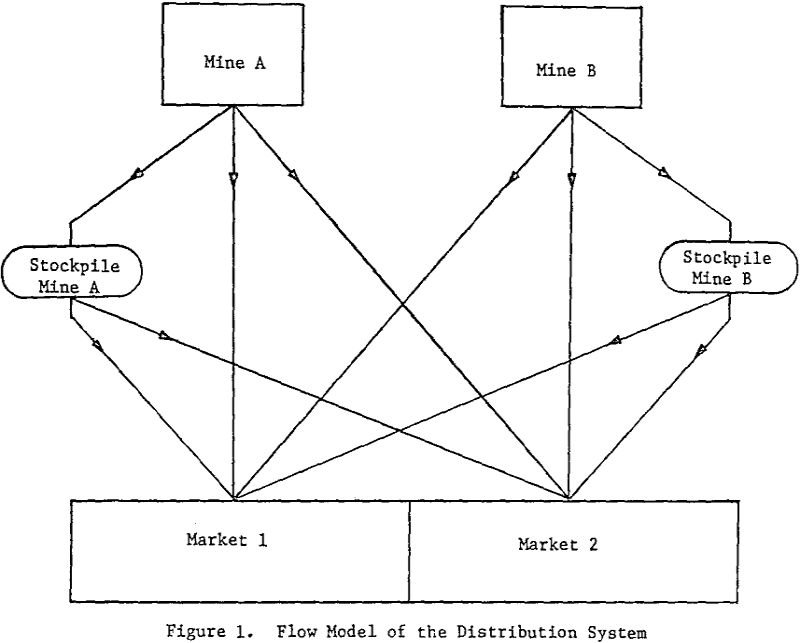

Mathematical Programming of Crushing Circuits

Crushed stone operations have become more difficult due to rising costs of labor and equipment, with the consequent reduction in profit margins. Competition from other operators and the encroachment of vertically integrated companies place severe restrictions on available markets. The seasonal demand for stone precludes any definite production level, and changes in productivity have to […]

Conveyor Idlers Operating & Maintenance

Depending on the source of reference used, belts for handling bulk material underground came into being between 1900 and 1920, while strip mining appeared in the thirties. The conveyor belt speeds in that era were in the 300 fpm to 500 fpm range. Belt speeds of 600-700 fpm were in vogue in the fifties, and […]

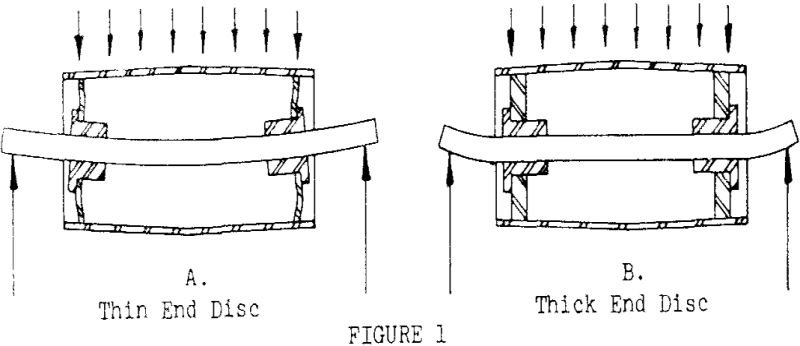

Conveyor Belt Pulleys Design Features

In belt conveyor application, a pulley’s purpose is primarily three-fold, 1) support the belt in directional changes, as designed in the conveyor, 2) transmit driving power to the belt, and 3) guide or train the belt. The drive pulley imparts the driving force to the belt and may be located at the head or discharge […]

Conveyor Belt Drive Selection

The drive selected for any piece of machinery must adequately satisfy the application requirements both during the starting interval and at running conditions. All loading possibilities of the drive must be known and allowances made for any adverse limiting conditions such as extreme cold, or perhaps an intermittent excessive loading situation etc. Characteristics of the […]

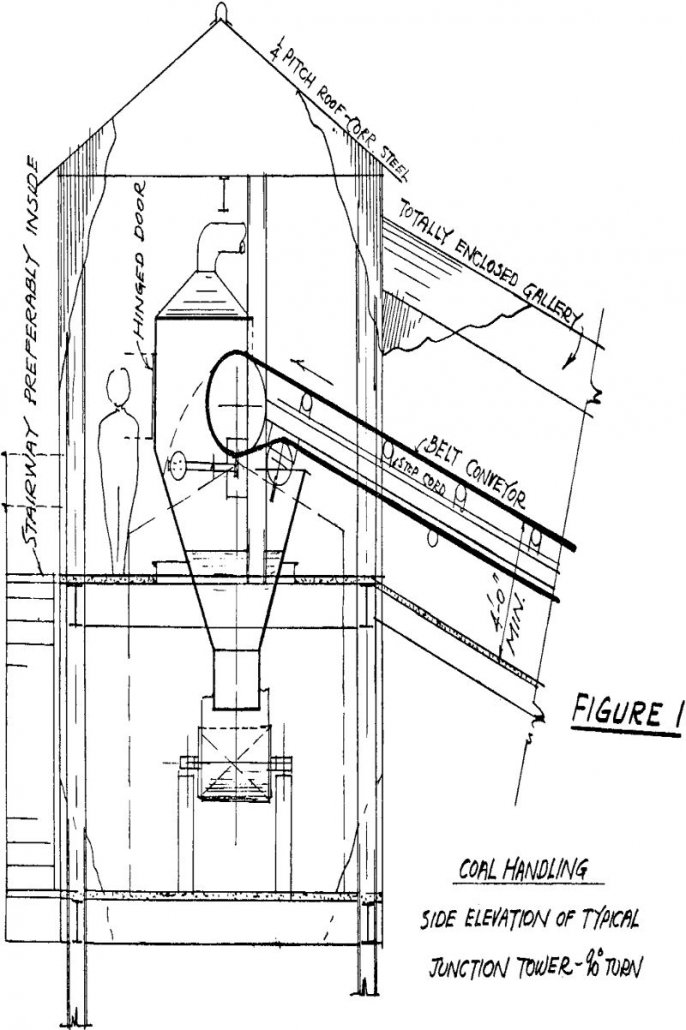

Belt Conveyor Transfer Points

Belt conveyors have proven themselves for many years as a dependable and low cost method of handling bulk materials at high flow rates. The success of a belt conveyor system greatly depends on the initial loading of the material on the belt. If the material is loaded on the belt at the center, at approximately […]

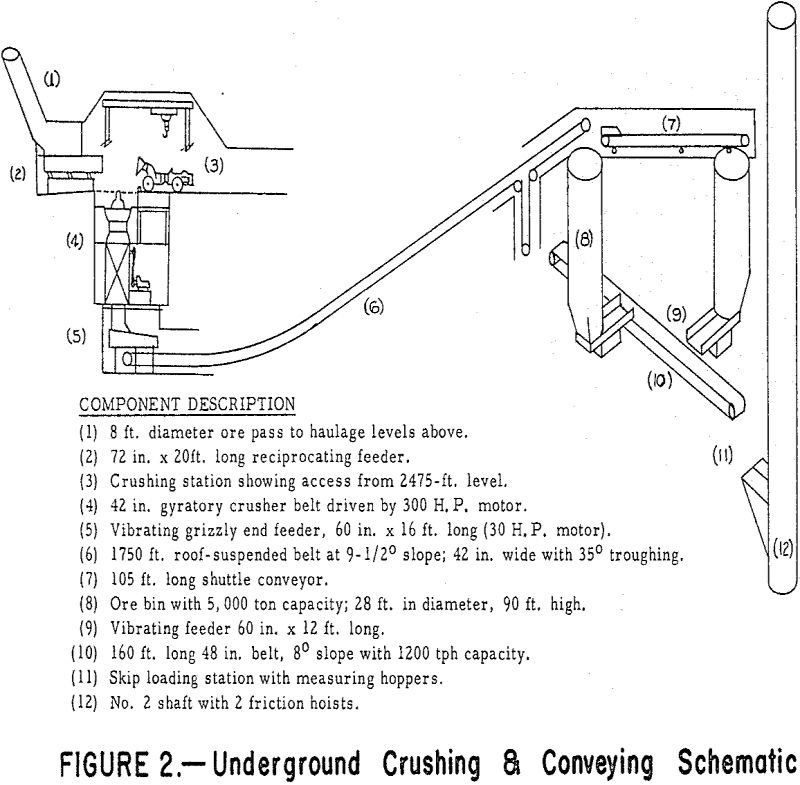

Installation of an Underground Crushing System

Meramec Mining Company, a joint venture by Bethlehem Steel Corporation and St. Joe Minerals Corporation, is engaged in the mining, concentrating, and pelletizing of iron ore from the Pea Ridge Mine located near Sullivan, Missouri, about 70 miles southwest of St. Louis. Crusher and Conveyor System Layout The heart of this system is a 42-inch […]

Mobile Crushing Plants

The transportation of mine products incurs a cost which can have a significant bearing on the competitive position of the product. This statement not only holds true for the transportation of the finished product but certainly as much for the in-plant haulage of the raw materials. First of all, it should be differentiated between 3 categories […]

VSI Crusher Vertical Shaft Impactor

In a vertical shaft impact crusher, the aggregate feed is introduced into a shoe or pump spinning on a vertical axis. The aggregate feed is thrown centrifugalLY against a series of anvils, pockets of aggregate particles (i.e., autogenous), or a combination thereof. Vertical shaft impact crushers produce a small reduction ratio and arc often used for […]

High Performance Jaw Crusher

The 911MPEFC250 is a Fine Jaw Crusher for pre-crushing of extremely hard up to brittle materials down to < 2mm in one step: End fineness 90% < 2mm Very Powerful Infinitely, reproducible gap adjustment Easily change of jaw plates and side liner Various infeed hopper: removable, with safety guard, batch loader and metering External control […]