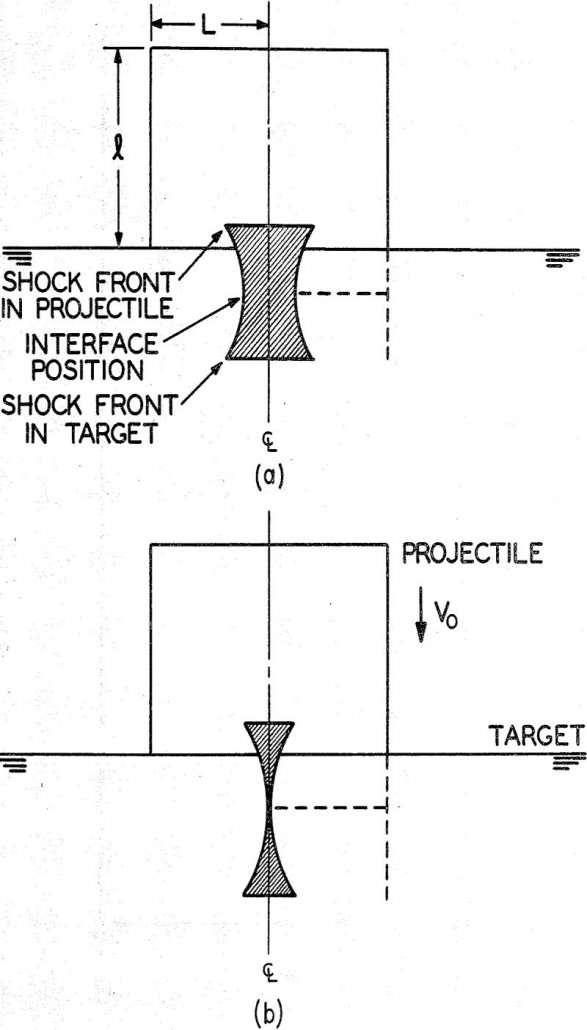

Comminution in Brittle Solids from Hypervelocity Impacts

Comminution is an old art. Unfortunately the analysis of the unit operations has been handicapped by the lack of both theoretical and experimental information. Two types of information are needed, one an understanding of what happens when a particle breaks in a brittle manner; and two, an understanding of what happens when the daughter fragments […]

Crushing and Grinding Circuit Automation

Most modern crushing and grinding facilities are automated to some degree. Some, of course, have a very minimum of automatic control whereas others utilize very complex control equipment. However, with very few exceptions, there has not been a new basic control philosophy applied in this field in the past seven years. The philosophy has been […]

Flow of Solids in Bins

There used to be a time when bins were designed for total volume and placed in any available place of the plant. Poke holes were provided and feed was maintained by manual prodding, lancing, hammering, and by various mechanical flow-promoting devices. Little thought was given to what occurred inside the bins and why materials did […]

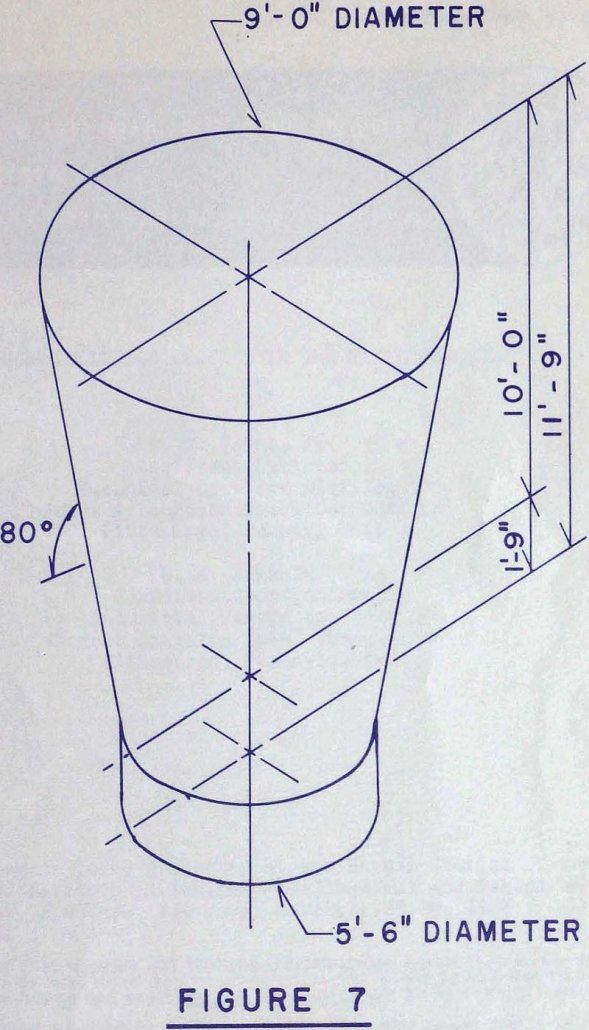

Bin Design and Construction

For many years, the Machinery Division of Dravo Corporation has been designing and constructing bins and bunkers as part of overall plant facilities. We have designed bins to handle a variety of materials including coal, coke, iron ores and concentrates, sintered and pelletized ores, calcined and raw limestone, bentonite, alloys for BOF shops, and even […]

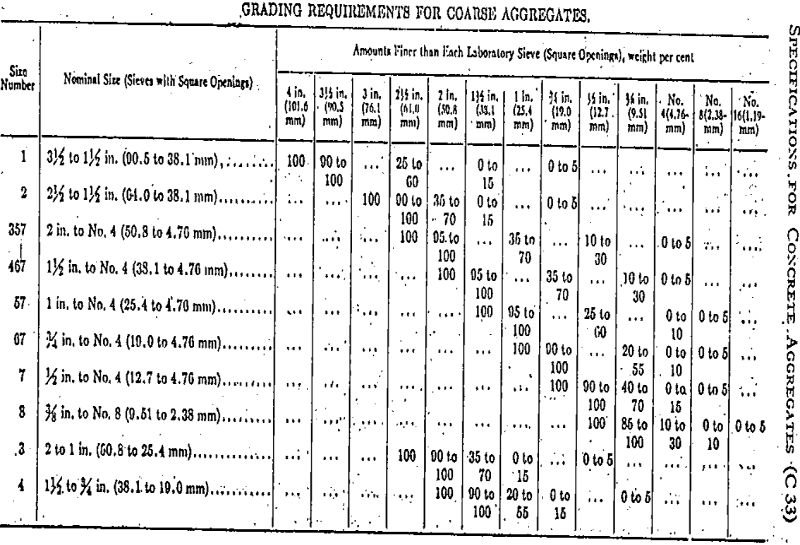

Crushing in the Aggregate Industry

In most industrialized countries, the largest element of the mining industry in physical volume is that devoted to the extraction and processing of materials for use as construction aggregates. These materials come from four main sources: (a) Excavation of unconsolidated deposits of sand and gravel (b) Stone quarrying. (c) Processing of slags and other mineral wastes. […]

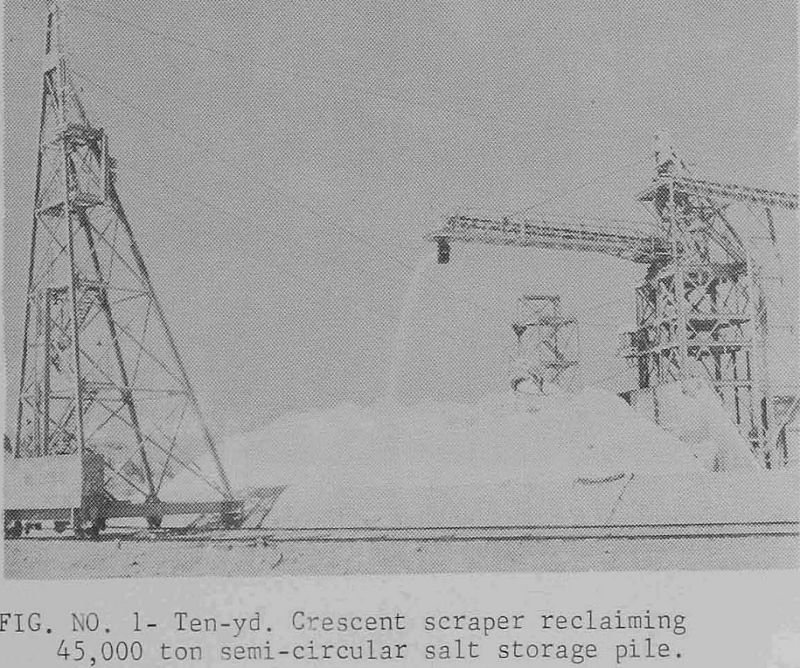

Dragscraper for Stockpiling, Reclaiming and Blending

Today more than ever, there is an increased demand for higher plant production capacities and efficiencies to offset the increasing costs for labor and materials. Plants involved in processing large volumes of bulk materials are particularly interested in more efficient material handling systems to (1) reduce labor and maintenance costs, (2) improve blending of non-uniform […]

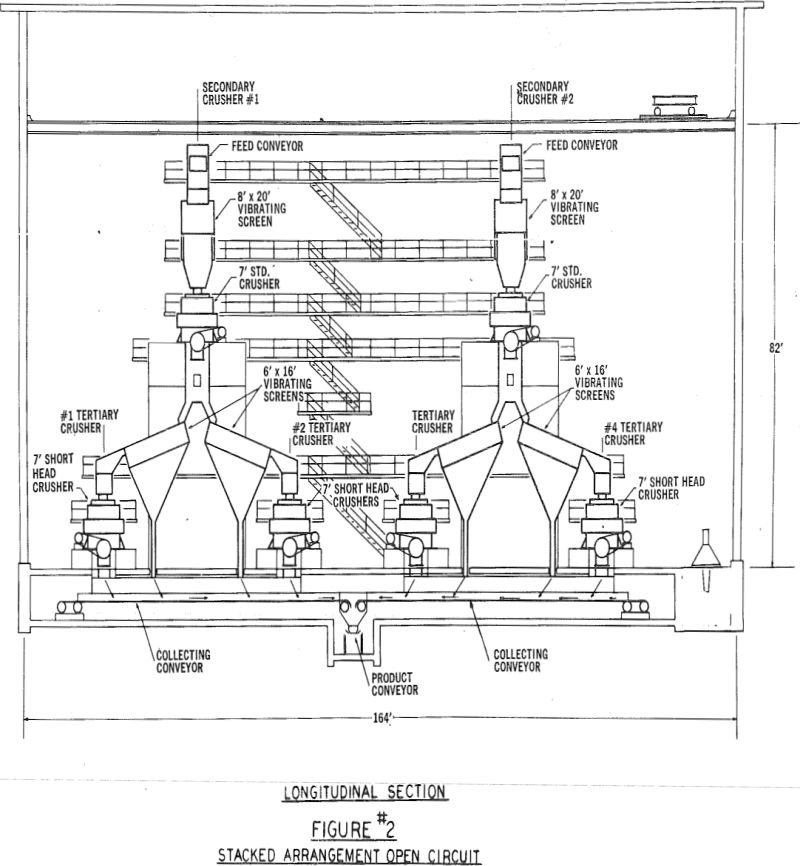

Large Tonnage Fine Crushing Plants – Trade-Off Study

Common practice for size reduction of run-of-mine or run-of-pit ore in preparation for subsequent treatment utilizes a three-stage system. First stage, or primary breaking is generally carried out with jaw or gyratory crushers. The usual output from this stage provides a feed for fine crushing in the size range of 6 to 10 inches. Factors […]

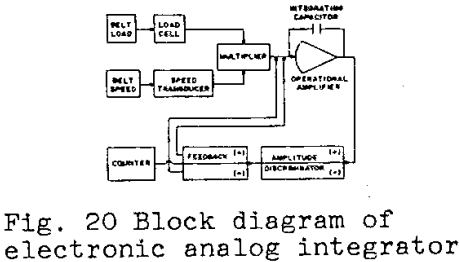

Conveyor Belt Scale Design

Weight may be defined as the gravitational attraction or earthpull on a body (mass). Thus, from a practical viewpoint, a scale or other form of weighing device is a means for determining mass. Weighing devices fall into two principal categories: (1) gravimetric; and (2) non-gravimetric or nuclear devices. At present, after many centuries of use, […]

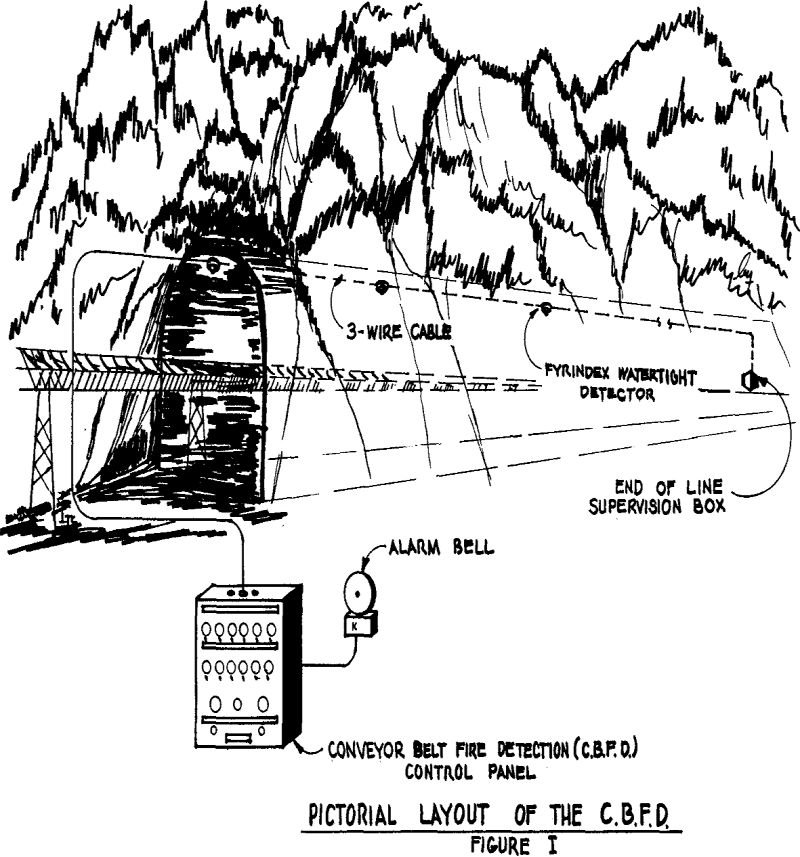

Fire Protection for Belt Conveyors

For more than fifty years Walter Kidde & Company, Inc. has engaged in the development and manufacturing of both fire suppression and detection equipment. Our initial work for the mining industry centered around dry chemical extinguishing equipment for mine haulage cars. To fulfill this need, Kidde engineered and developed a manually activated dry chemical system […]

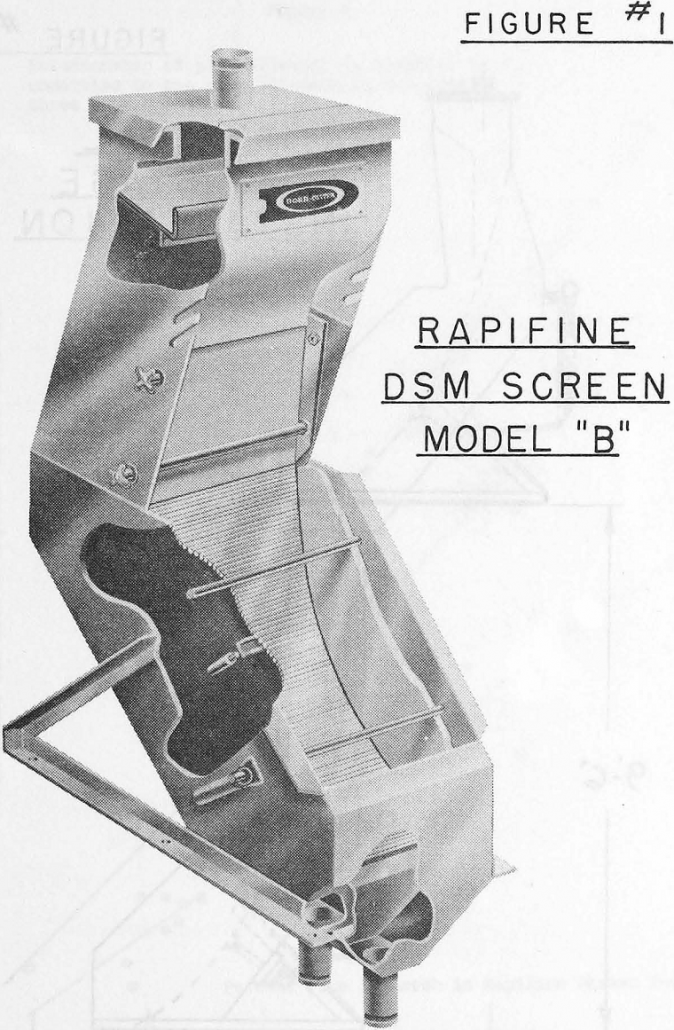

Fine Screening

Fine screening, as discussed in this paper, pertains to the use of the Rapifine DSM Screen to make a 65 to 325-mesh separation at production tonnages. The greatest number of Rapifine Screen installations are in magnetic taconite plants where the unusual relationship between the grinding mill, cyclone classifier, magnetic separators, and fine screens makes the Rapifine […]