Belt Conveyor Design

Idlers: Due to the efforts of the Conveyor Equipment Manufacturers Association, the basic idler elements—idler roll wall thickness, bearing sizes and shaft sizes—have been standardized into classes. There is also a substantial dimensional commonality as well. Belting: Again, the rubber manufacturers have standardized, either by agreement through industry associations, or by following the leader and […]

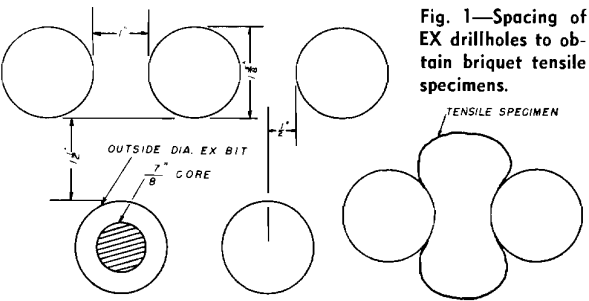

How to Measure the Tensile Strength of Rocks

Principle and equipment are the same as for the test for tensile strength of hydraulic-cement mortar. The test specimen has the shape of a briquet. While in the original cement mortar test the briquet is cast in a special mold, it is prepared from rocks in different ways, depending on how easily they can be […]

Comminution: Energy-Size Reduction Relationships

Search for a consistent theory to explain the relationship between energy input and size reduction in a comminution process has accumulated, over the years, an enormous amount of plant and laboratory data. Although some correlation of these data has been possible for purposes of engineering design and for the advancement of research in fracture, there […]

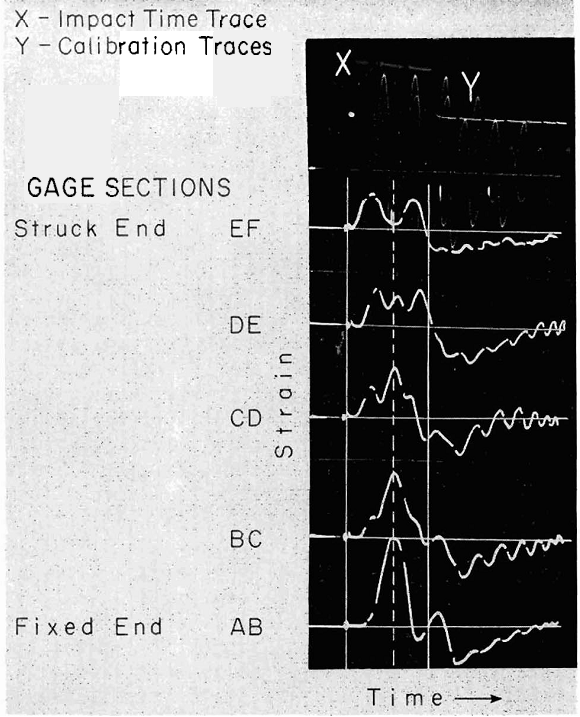

Grinding Energy Transfer by Impact

The transfer of kinetic energy of translation into other forms of energy by impact is a fundamental process in most crushing and grinding operations. During and after the impact process the original source energy may be accounted for in any of the following possible forms: Kinetic energy of translation of both the impacted and impacting […]

Underground Conveyor

The Inland Steel Company operates five underground iron mines in the Lake Superior District. The two largest of these, from the standpoint of productive capacity, are the Sherwood Mine in Iron River and the Bristol Mine in Crystal Falls, both on the Menominee Range of Michigan. It is at these two mines that we have […]

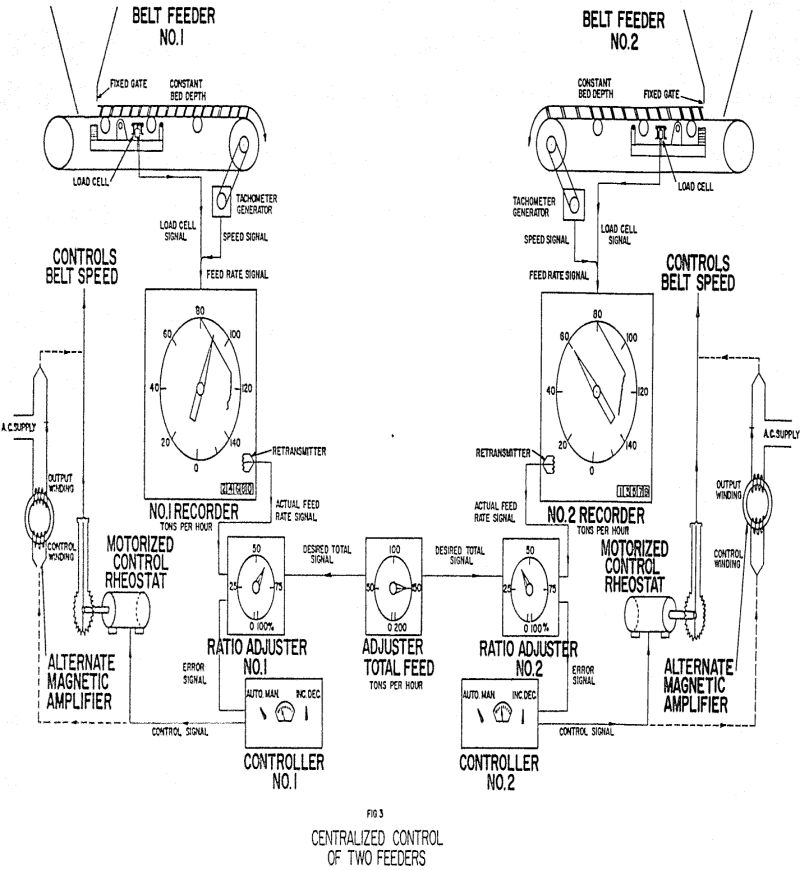

Automatic Weighing and Ratioing of Solids

Plants which process materials in the form of bulk solids have not been able to use control to as great an extent, primarily due to the lack of measuring equipment capable of providing the same types of continuous automatic control available with liquid flow meters. A conveyor belt idler is supported on a rigid carriage […]

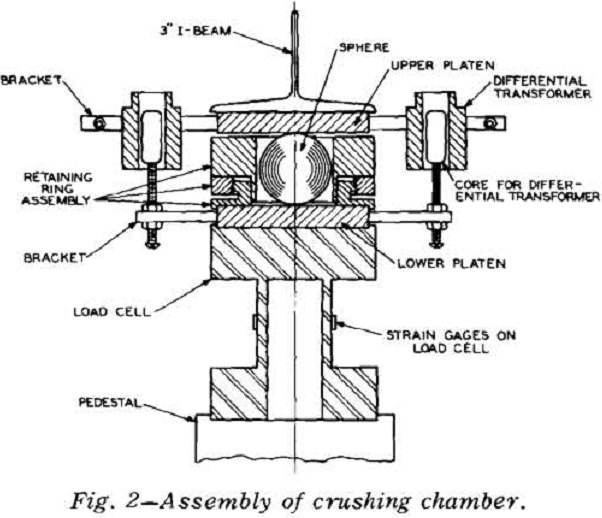

Energy Aspects of Single Particle Crushing

A unique compression testing machine was constructed to load individual 1/8 to 1-in. spheres of glass, etc., at rates from 100 to 100,000 lb per min. During loading the applied load was continuously plotted vs the deformation of the sphere-platen system. The load-deformation curve conforms to the theory of elasticity. The data shows.- 1) Energy […]

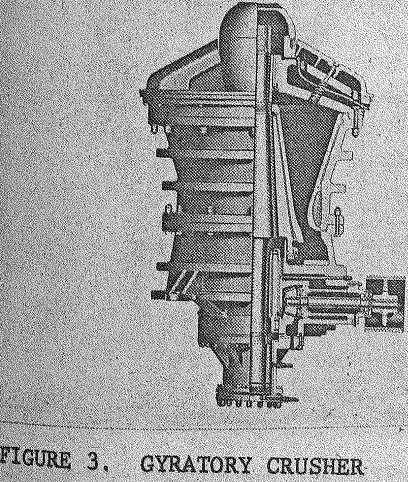

Preparation and Production of Mineral Aggregates

The preparation of aggregates is a form of mineral processing which has been taken for granted for many years, mostly because of its lack of glamour when compared to the winning of metallic minerals from their ores. Many of the processes and equipment now used in the metallic mineral processing industries originated in the more […]

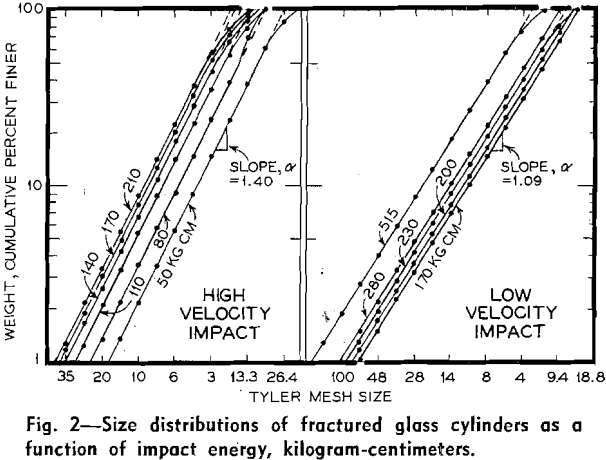

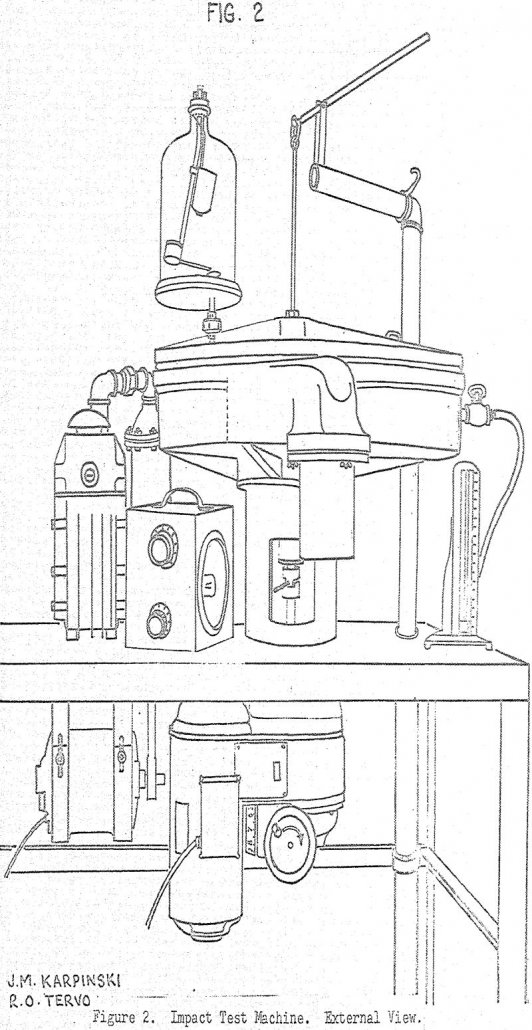

Single Impact Testing of Grains of Brittle Materials

A method and equipment have been developed for measuring the impact strength of grains of brittle materials. It is shown that brittle materials develop a characteristic particle size distribution when fractured by impact. A simple mathematical model has been found to describe this distribution, and one of the parameters of the model has been designated the […]

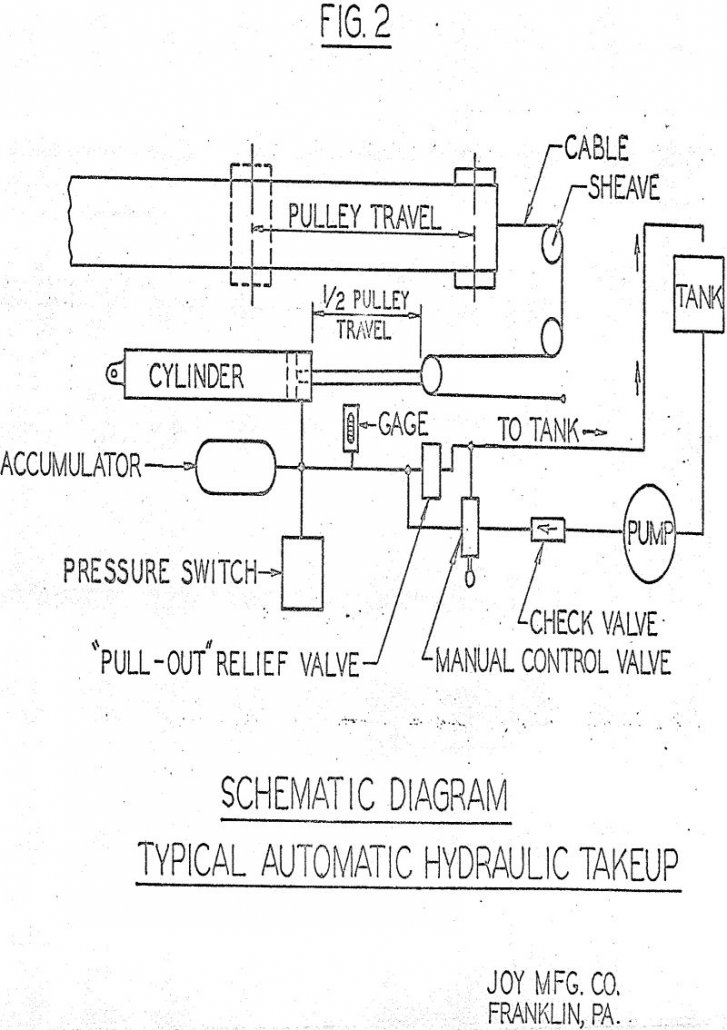

Automatic Hydraulic Takeups for Belt Conveyors

Since the majority of mines were then using direct current power systems, we were able to use controllers with 3 or more steps of starting resistance. The slow belt speeds coupled with relatively long starting cycles kept the rate of acceleration low and gave us smooth, easy starts. The conveyor belts in common use were […]