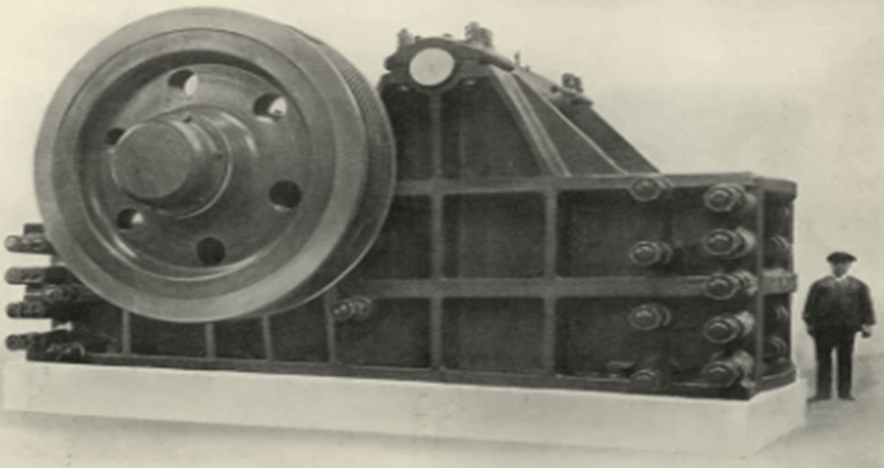

Antique Jaw Stone Breaker

TON RECIPROCATED Antique JAW STONE BREAKER: Curved by owners in installing and operating individual pumping plants. The new mechanical filtration or rapid sand filter plant for Baltimore comprises 32 filters each of 1440 square feet area and a capacity of 4,000,000 gallons daily. The turbidity of the water led to the adoption of this system in […]

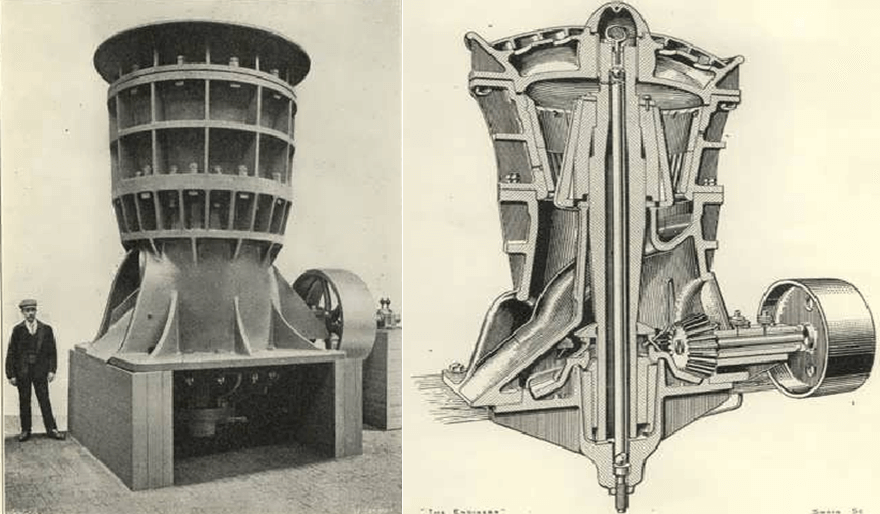

Antique Rock Crushers

Primary stone: Antique Rock Crushers AND rock breaking machines – if we may so designate those machines which are employed to reduce large masses of rock to sizes such as can be further dealt with by other machines – may be divided into two headings, i.e., (a) those which work largely used in those portions […]

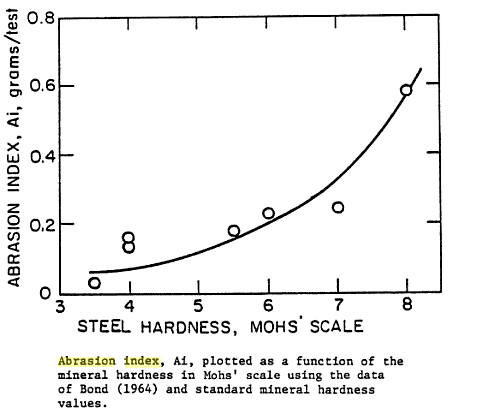

Bond Abrasion Index VS Mohs Mineral Hardness Scale

Here is an illustration of the typical relationship between the Mohs Mineral Hardness Scale and their corresponding Bond Abrasion Index. ref

Ore Feed Size * Work Index Hardness: Crushing & Mill Tonnage

The single most common reason for an increase or drop in the production of fines is the WORK INDEX of the ore. If you remember, the work index of the ore is a method of measuring the degree of hardness. As the ore becomes harder the fracture lines in the rock become cleaner or sharper […]

Vibrating Screens & Safety

Around Vibrating Screens, the 2 primary Safety considerations to have in mind are NOISE and DUST. These two are harder to deal with than most because of their nature. A hazard that involves blood and pain is an immediate thing and very easy to understand. But something that may take years of development before it […]

How Mine Trash affects Crushers

Am talking about circulating garbage! In every crushing plant there are objects other than rock put into the feed. It may be rubber, from the tires of the mining equipment. It could also be wood or wire that was accidently put into the coarse ore feed. This type of refuse is too large to go through […]

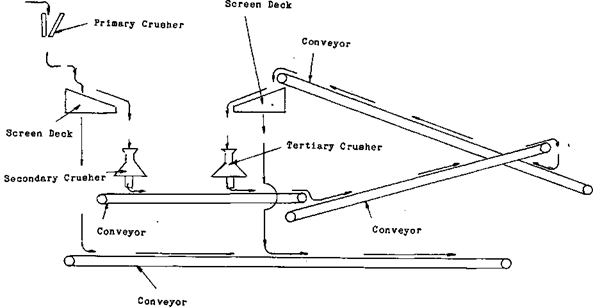

Balancing a Crusher & Vibrating Screen Circuit

To understand the effects the plant has on itself during its actual operation is very important. There are three variables that the plant on a whole is affected by: VOLUME (or tonnage) SIZE OF FEED CIRCULATING GARBAGE (wood, plastic, rubber, etc.) The first two the volume and the size of the feed effect one another, […]

Polyurethane Screen Panels

These Polyurethane Screen Panels are often installed on SAG discharge trommel screens or AG vibrating screens and even crusher circuits. Polyurethane Screen Panels are best when made of low “durometer” Polyurethane to allow a “bouncing” effect for the rocks and reduces wear.

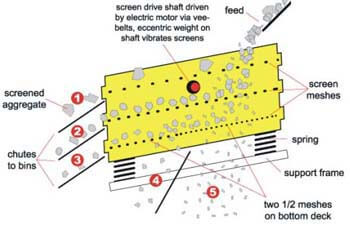

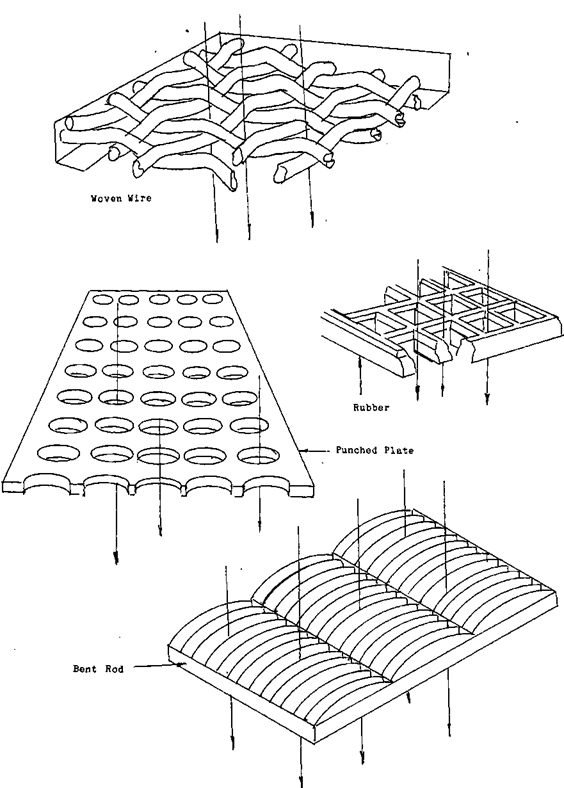

Various Types of Screen Decking

In some designs it is very easy to replace portions of the deck in just a few minutes. In the bigger screens to replace just a portion takes time, with these decks a screen will be temporarily patched. Just putting a patch on does two things, first allows the repair to be done when it […]

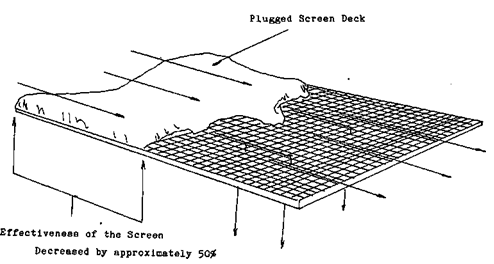

Effect of Moisture on Screen Efficiency

When you are supervising a set of screens these are the variables that you have to watch for: SPEED OF VIBRATION: DEGREE OP SLOPE: TONNAGE: WETNESS or Moisture OF THE ORE: MECHANICAL CONDITION: The operator will have two or three indications that As an operator you have control over two of these variables, mechanical […]