Manual & Hand Operated Rock Crusher

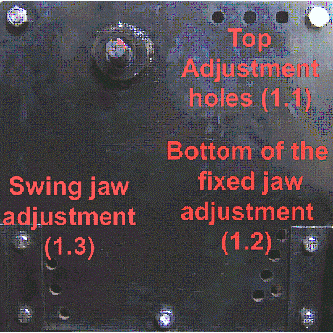

HOW TO SETUP AND USE THE HAND OPERATED ROCK CRUSHER: The rock crusher is shipped with the handle screwed to the inside of the flywheel. This must be reversed. In the case of the double flywheel version there are two handles. The handle has two flats to accept a 24mm spanner right against the flywheel. Use […]

Small Jaw Crusher for Sale

https://www.911metallurgist.com/equipment/crushing/

Vertical Shaft Impactor

Gold Milling Process -Primitive and Basic

Here is an Ancient Gold Ore Milling Process used in China in the 1800s. We might use it again after WW3. At the time, 1890, the Author said “There is, of course, nothing for us to learn from this imperfect and rudimentary gold-extraction process described here, which is doubtless destined to disappear ere long, before the […]

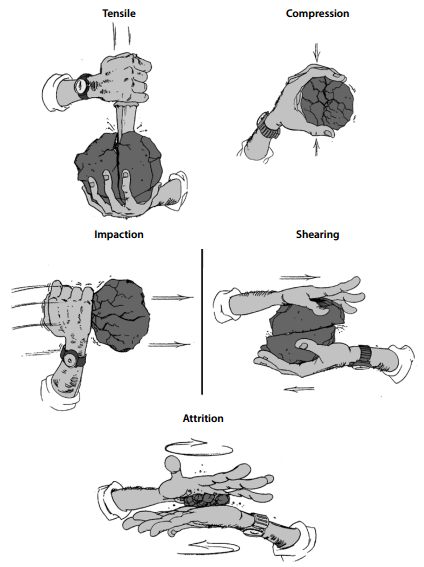

Crusher Reduction Ratio

I have mentioned the fact that, as the % of voids in the crushing chamber decreases, the production of fines by attrition increases. This is like saying that, as the Crusher Reduction Ratio in any given crusher is increased, the % of fines in the product will increase, even though the discharge setting remains unchanged. Both of these statements […]

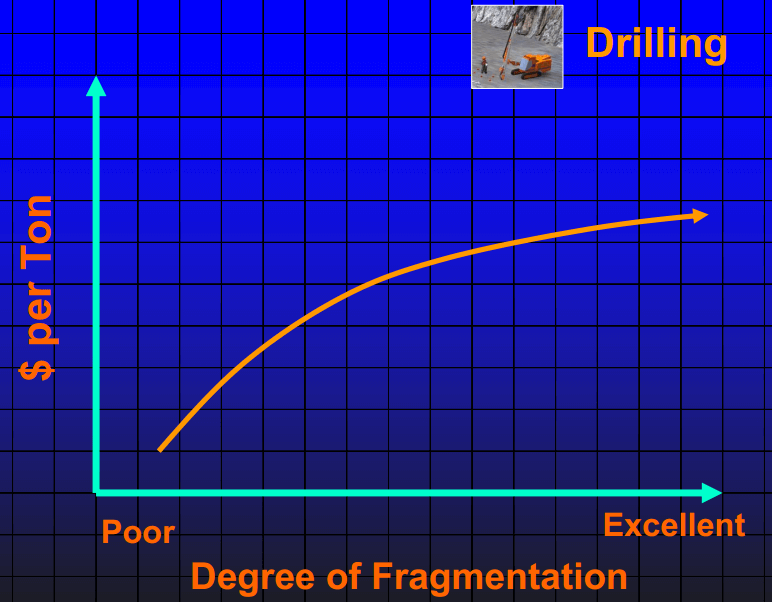

Crusher Operating Costs: How to Optimize and Reduce

Spending a little extra on drilling and blasting to increase fragmentation will same you multiples ore loading and hauling, then finally crushing. The Experts: SandVik Mining + Metso and Quarry Academy = all agree. The approximate running costs for crushing plants of different capacities up to 4,000 tons per day on the basis of an eight-hour crushing day are easy to […]

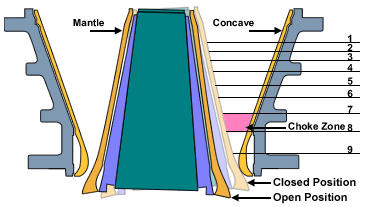

How to Prevent Crusher Choking

We all understand how choke feeding a crusher makes for good operation and product size but operators need to also know How to Prevent and avoid that same Crusher from Choking. It is apparent that although the distance between successive horizontal planes increases gradually as these planes move downward (due to increased throw of the […]

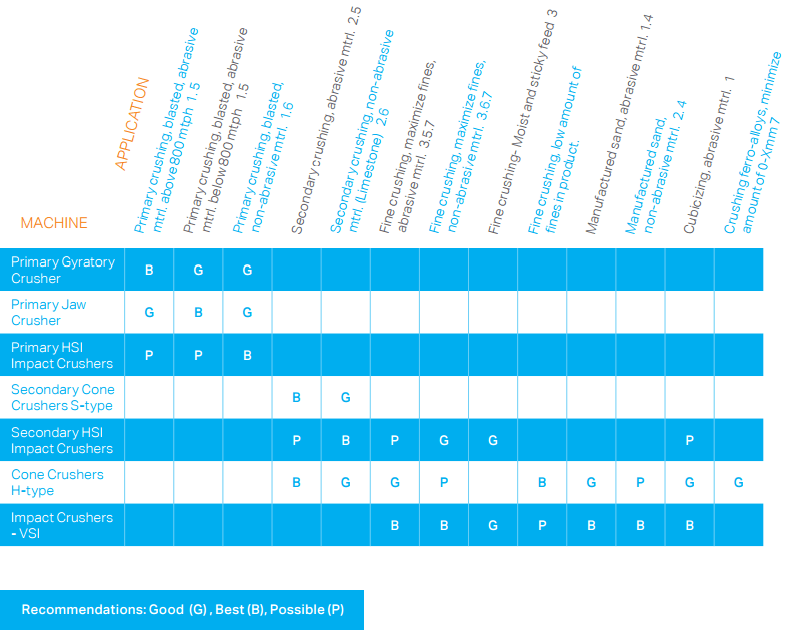

Crushing in Mineral Processing

In mineral processing or metallurgy, the first stage of comminution is crushing. Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks. In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wear-resistant plate/surface. Less abrasive […]

Jaw Crusher with “Multi Jaws” for Fine Crushing

The Bakstad’s Patented Multiple Jaws, is a Jaw Crusher that represents the first real advance made in increasing the crushing range of jaw crushers since their introduction. This Is the only crusher designed to give you a primary and two secondary crushers in one unit. Crushers of the jaw principle type have conclusively demonstrated their superiority over other […]

Primary Crusher Selection & Design

How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not. The crusher capacities given by manufacturers are typically in tons of 2,000 lbs. and are based on crushing limestone weighing loose about 2,700 lbs. […]