How to Test the Strength of Rocks

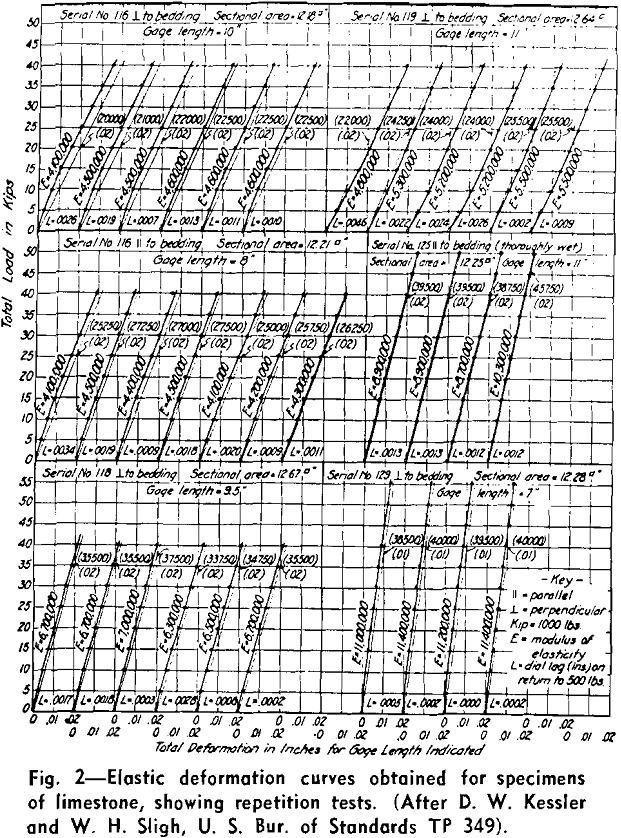

This paper reviews the progress made in testing the strength of rocks, ores, coal, salts, and other minerals as they are encountered in mine operations. It attempts to correlate the results of these physical measurements with technological properties more useful to the mining engineer: abrasive hardness, grindability, and behavior in comminution on one hand, and […]

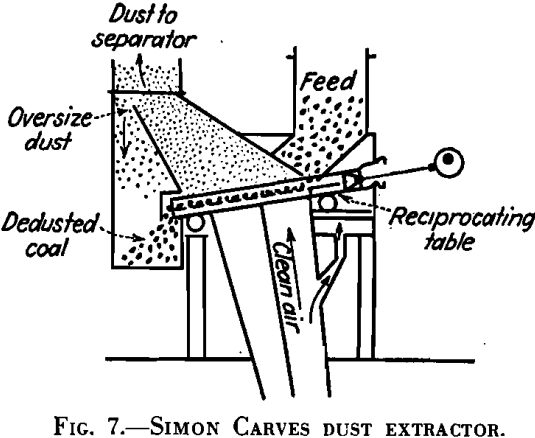

Dedusting and Dust Collection

It is generally accepted that no method of coal cleaning except froth flotation is effective in cleaning dust. In the majority of coals mined in the United States the dust sizes contain a high percentage of impurities, hence the removal of the dust from the coarse sizes lowers the impurity content of these sizes. Dedusted […]

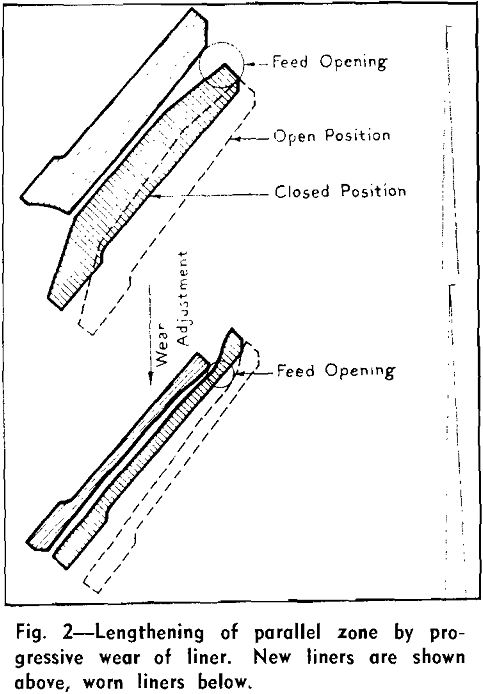

Crushing Cavity Design

In these times of rising labor and material costs, it has become more and more necessary that attention be paid to some operating details which, in their obscurity, may be the key to major economies. Liner wear in crushing cavities of secondary and tertiary crushers can become an appreciable cost item when the material to […]

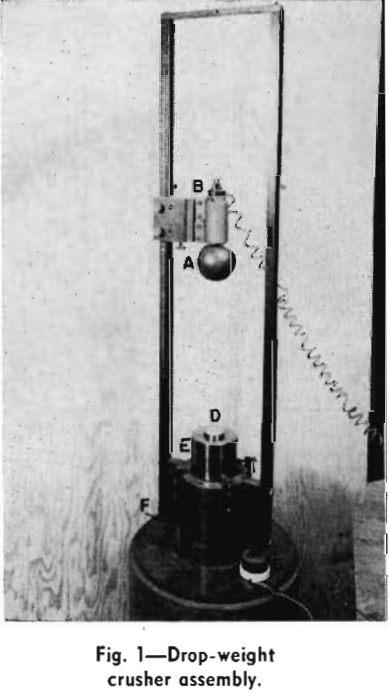

Laboratory Crushing Tests

Crushing has always been a major operation in the chemical and metallurgical industries, yet little is known about the theory of crushing, and today, the design of crushers is still based almost entirely on empirical knowledge and accumulated practical experience. In view of the increasing national need for the economic working of poorer grades of […]

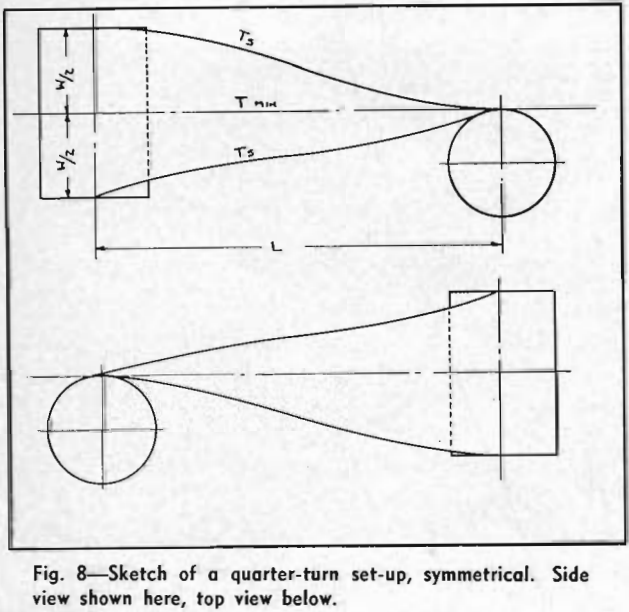

Two-Way Belt Conveyor Transportation

Since 1920 use of belt conveyor transportation has increased steadily, and capacity in tons per hour per unit has increased at about the same ratio. Belt conveyor systems for simultaneous two-way material transportation have been widely discussed, but heretofore have proved impractical for specific operations. The two-way belt conveyor for coal mine service is not […]

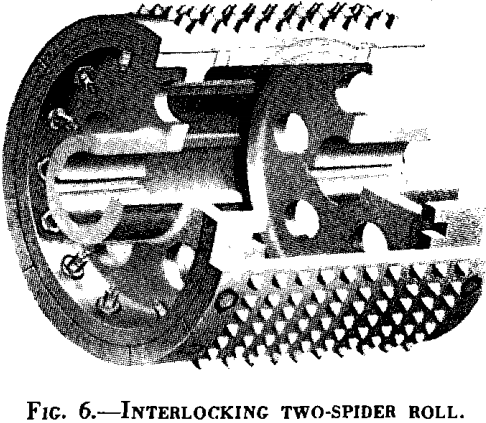

Rock Breaking Machine

Anthracite Small power-driven, toothed, cast-iron rolls were used first to break anthracite in 1844. Prior to that time, men with hammers, who stood on perforated cast-iron plates, broke the large lumps into commercial sizes. In order to convert run-of-mine into the various sizes required by the anthracite industry, about 20 million tons must be broken, […]

Rock Hardness & Drilling

A survey of the technical literature concerned with oil well drilling methods and particularly with rate of penetration by various cutting media on different types of rock provides a mass of conflicting data. This is especially true with respect to, (1) the relative efficiency of diamond, rotary and percussion drilling operations; (2) the costs of […]

Tramp Iron Detector for Conveyor Belts

The problem of tramp iron removal from moving ore belts is a long standing one. When heavy ore streams are carried on a belt, magnetic pulleys and strong surface magnets fail to remove tramp buried in the ore stream. Tramp iron buried in the ore stream cannot be pulled from the bed by surface magnets […]

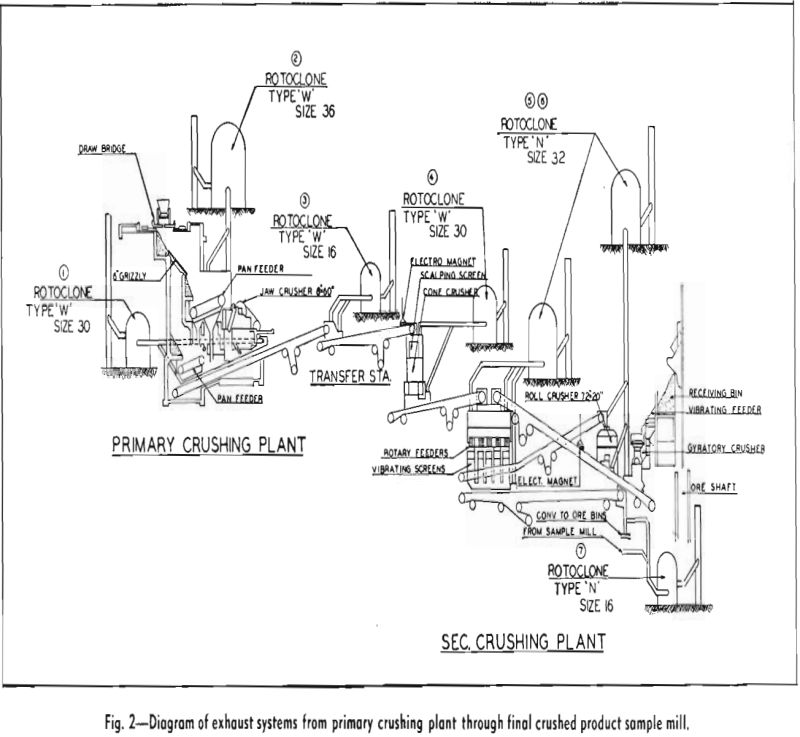

How to Control Dust in Crushing Plant

In 1947 an Industrial Hygiene Department was organized to represent and assist the four western mining divisions in industrial hygiene problems. Department headquarters are located at the Utah Copper Division, Magna Plant, Magna, Utah, with a branch office at the Chino Mines Division, Hurley, N. M. The headquarters staff includes a director, a department secretary, […]

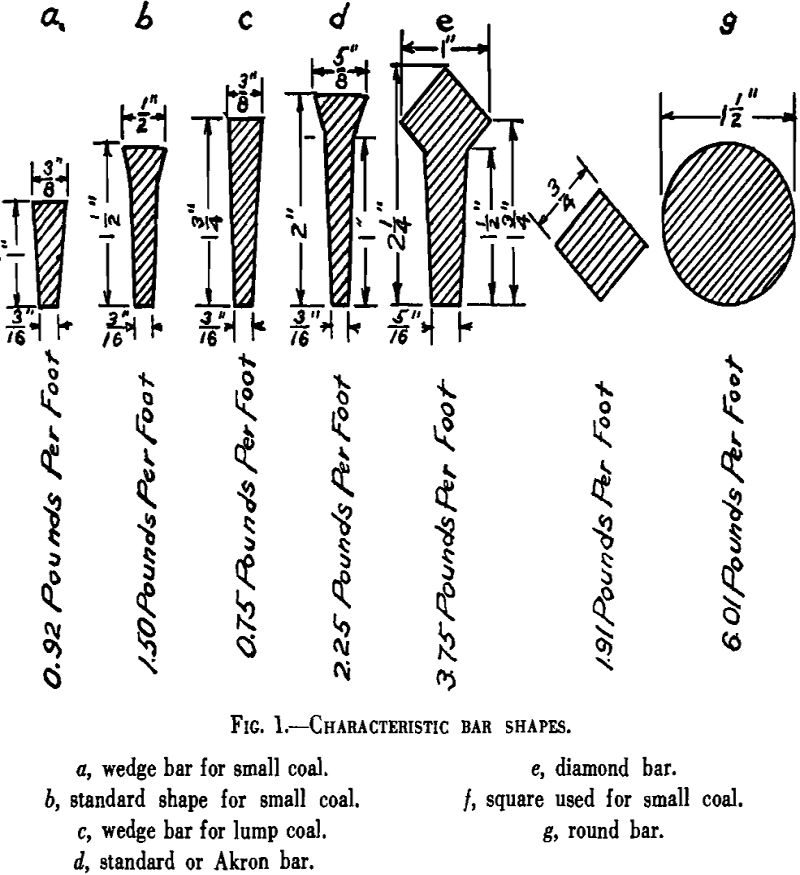

Screening Equipment

Sizing is the process of separating mixed particles into groups of particles all of the same size, or into groups in which all particles range between certain definite maximum and minimum sizes. In coal preparation, sizing is generally accomplished by passing the coal over screens. Separation by differential settling in air or water currents has […]