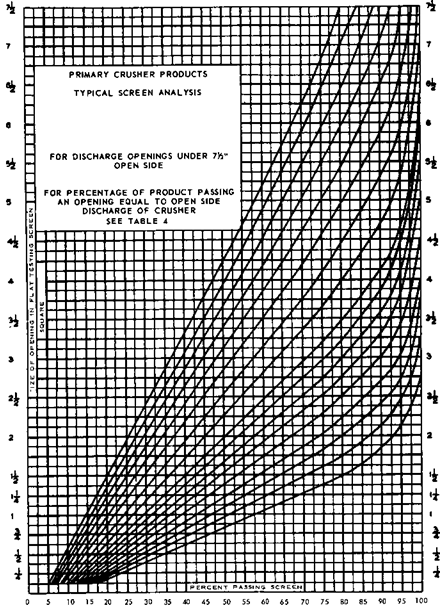

Crusher Product Gradation Charts

Aggregates required for a given job are generally specified by a full set of gradation limits and other relevant properties of the material. When rock is crushed, the product includes material of the size of the crusher setting, some slightly larger and the rest of the material smaller than the crusher setting. Crusher manufacturers publish grid […]

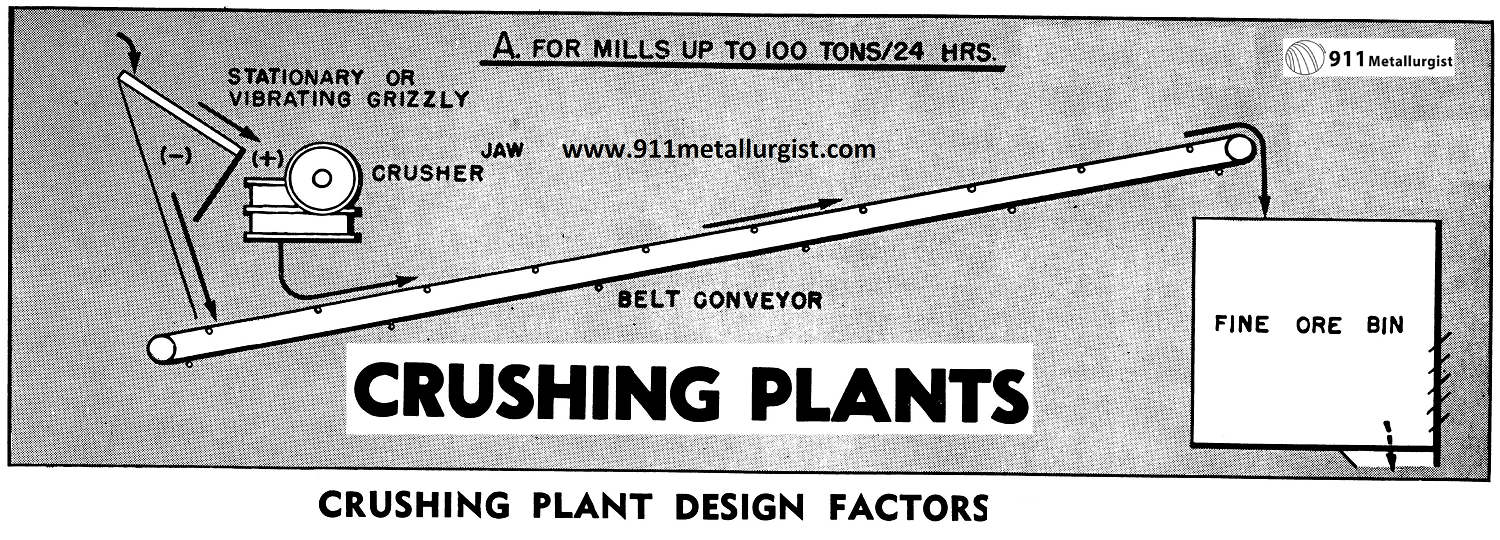

Crushing & Screening Plant Design Factors

Crushing Plant Design and Layout ConsiderationsCrushing Circuit “A’’ shows a small simple layout for use in mills up to 100 tons. In order to keep the flowsheet simple, and because of the use of the forced feed type of crusher, we can crush small tonnages up to 100 tons per day with a very simple […]

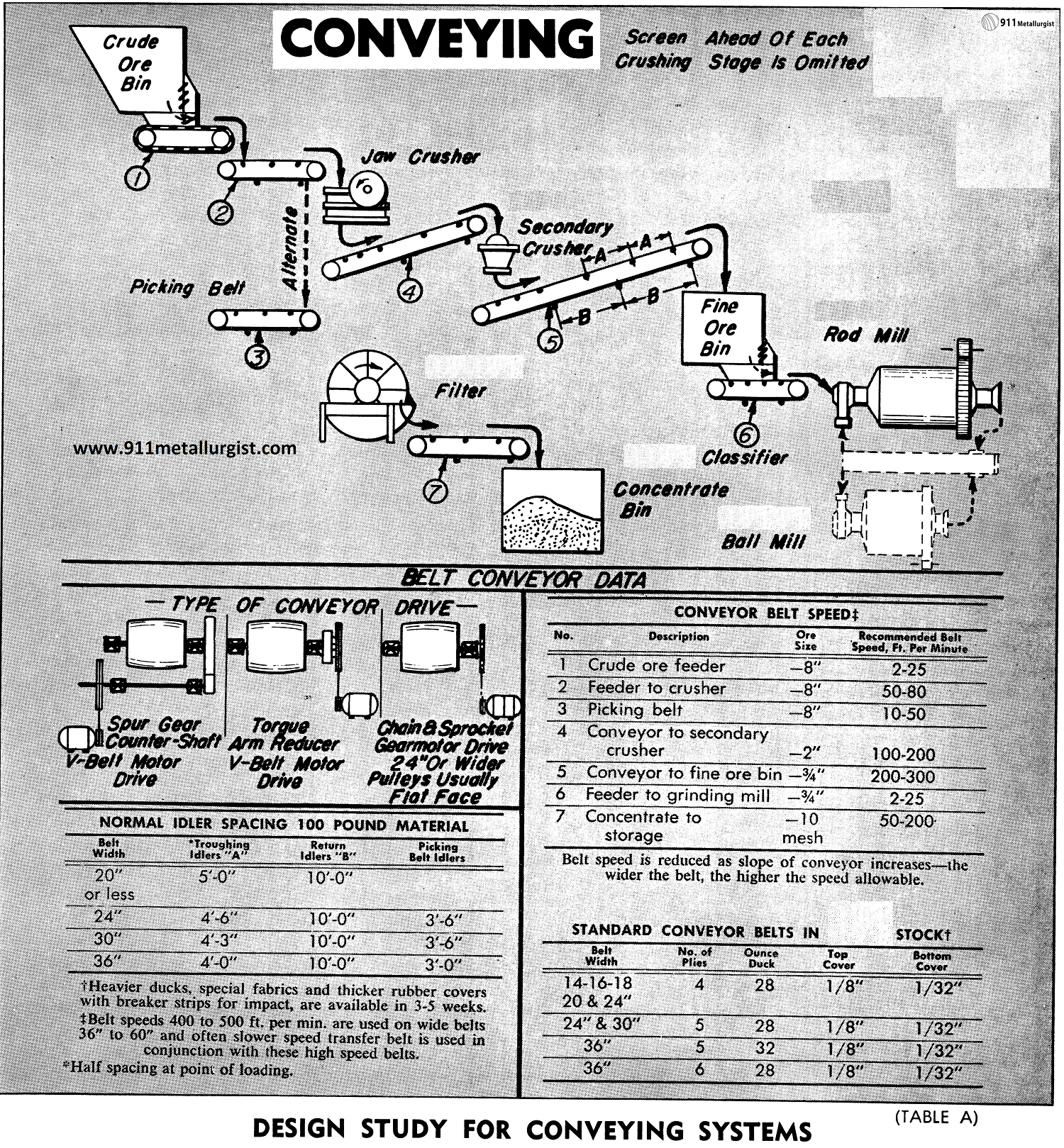

Designing a Conveyor System

The Problem with Designing a Conveyor System The designer of belt conveyors is often faced with problems of determining the proper belt speeds, belt widths, number of plies in the belt, and idler spacing for conveyors employed in various parts of a mill. Equipment Company offers the following data and tables, based upon many years of […]

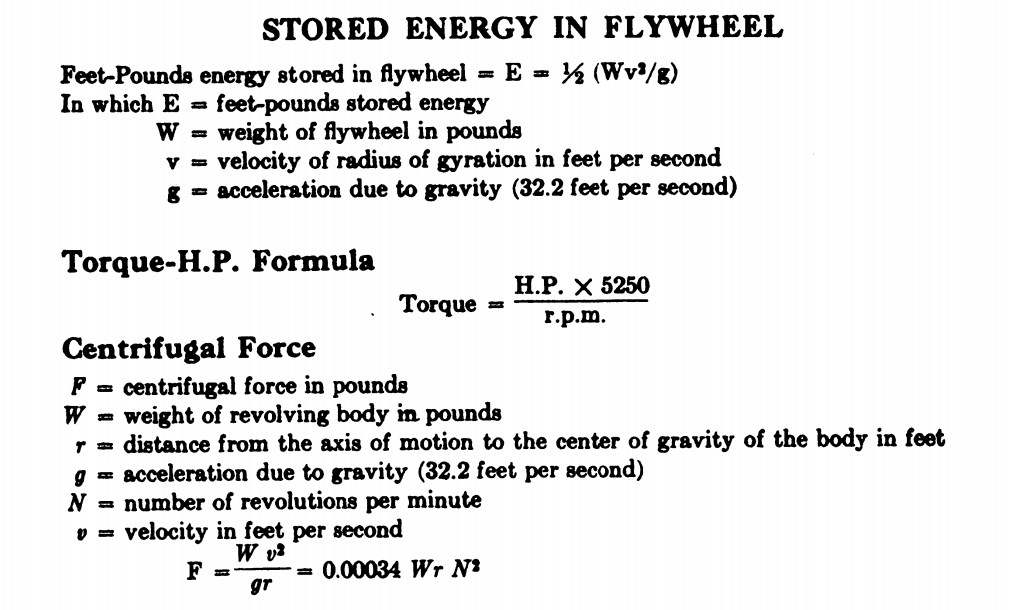

Calculate How Much Energy is Stored in a Flywheel

Troughing Belt Conveyor Capacity

Note. Above capacities are based on the assumption that material will be fed to conveyor uniformly and continuously. If loading is intermittent the conveyor should be designed for the maximum rate of loading likely to occur. For flat belts not troughed, use one-half of the above capacities. https://www.911metallurgist.com/estimating-conveyor-slope-angle

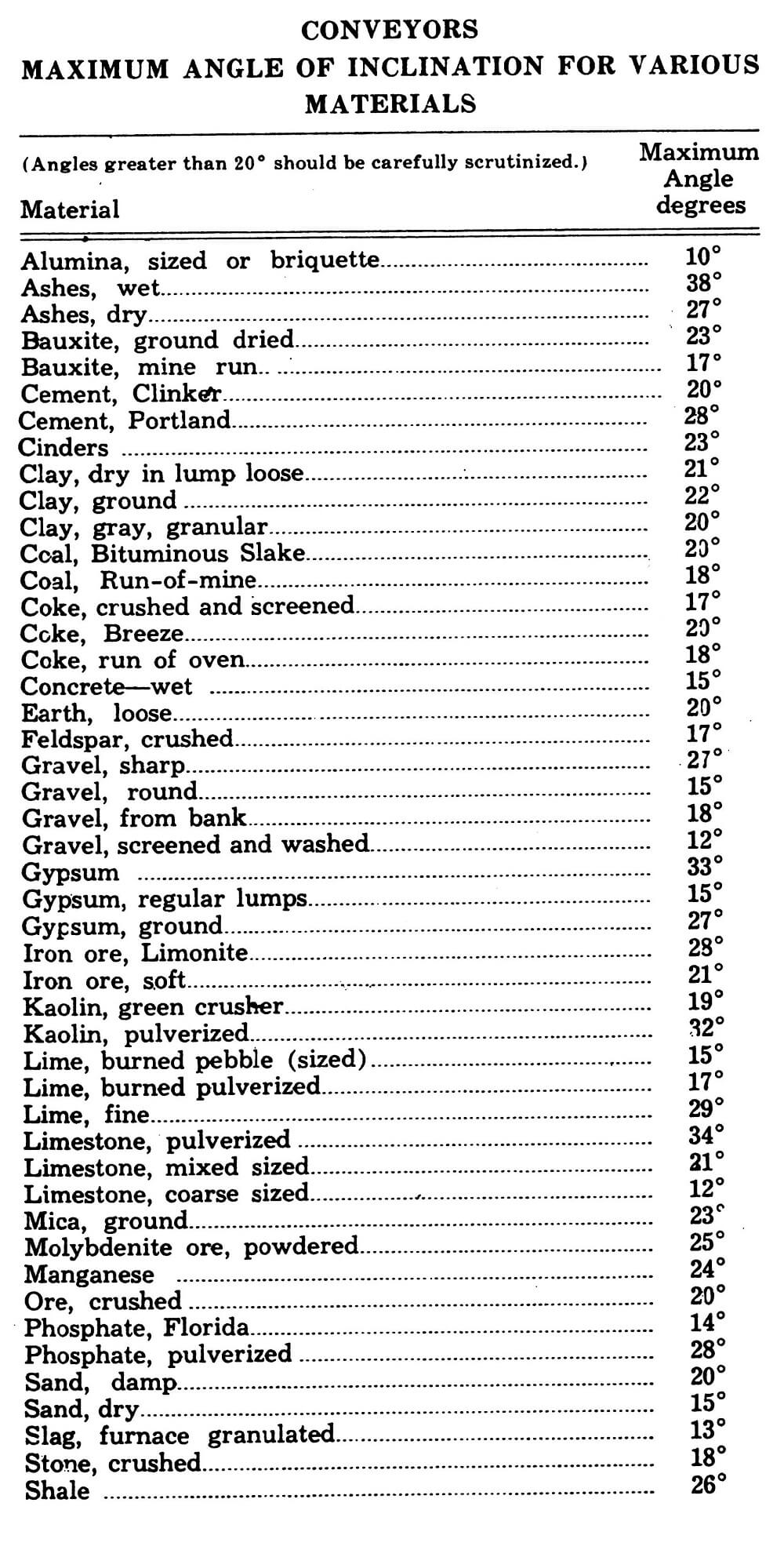

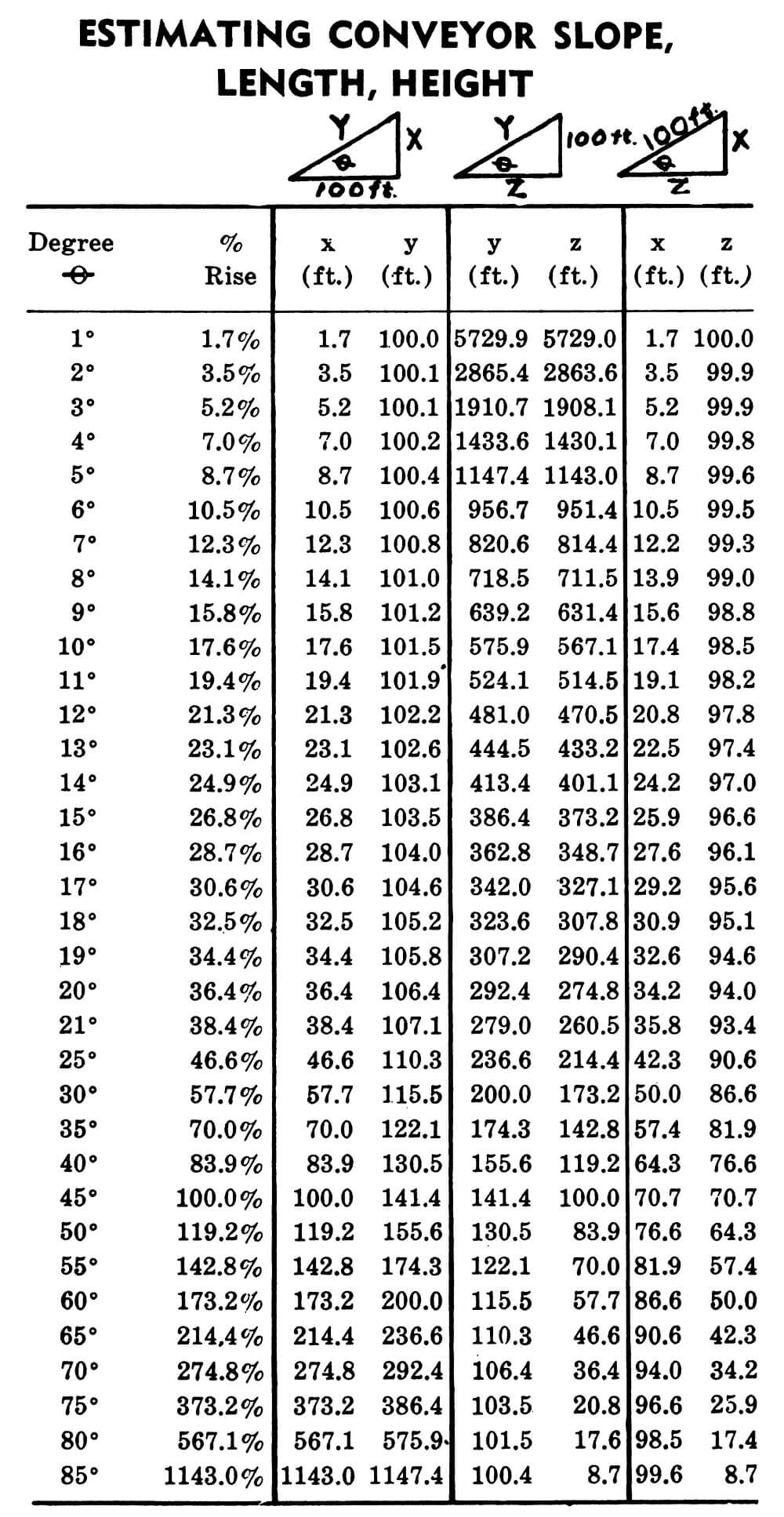

Maximum Conveyor Angle of Inclination

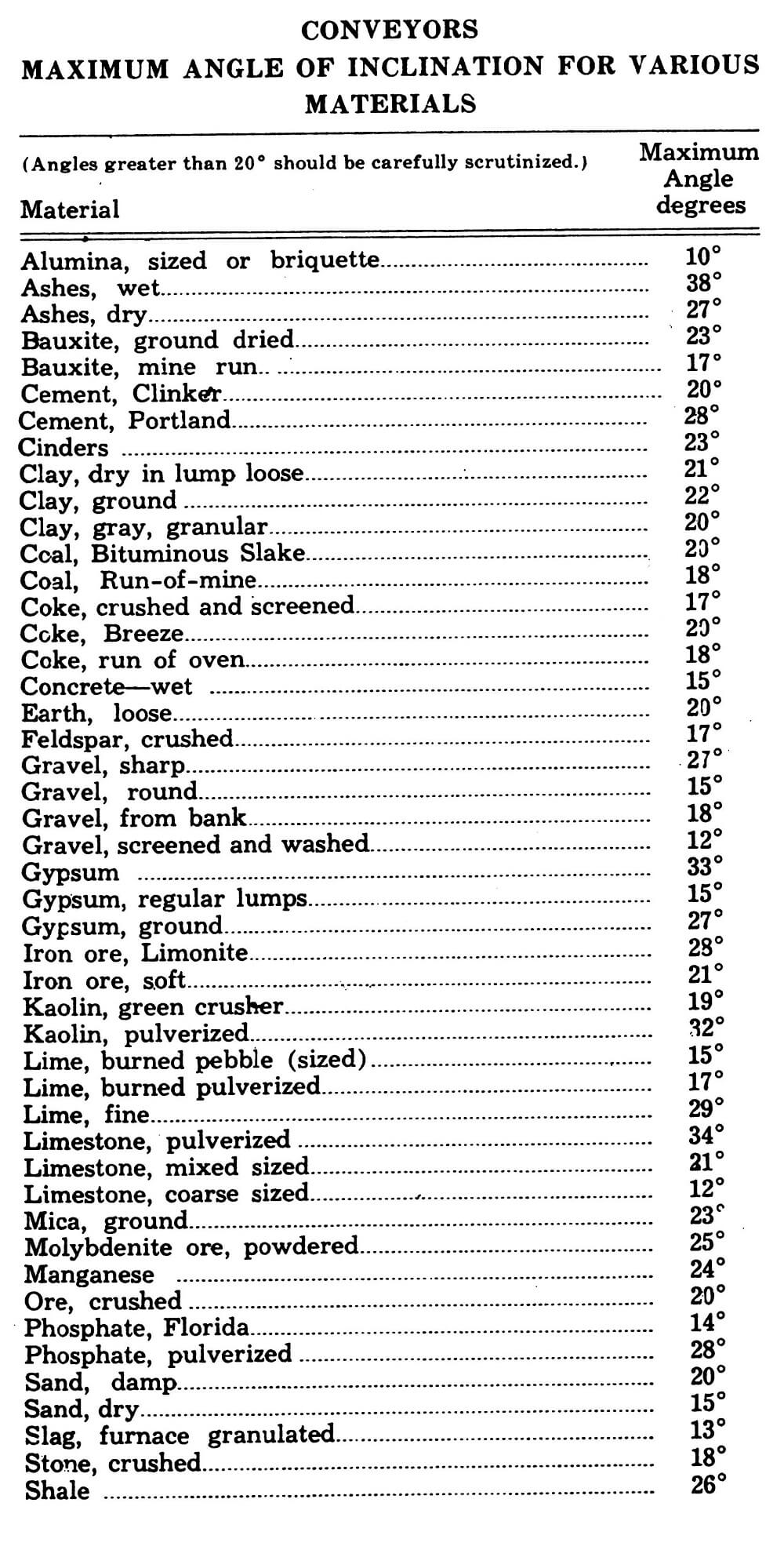

This chart consists of triangles representing horizontal, vertical, and inclined distances. Any one unknown distance can be determined when the other two are known. For distances greater than the limits of the chart, divide the given dimensions by a figure to bring within the range of the chart. Multiply the result by the same figure […]

Estimating Conveyor Slope and Angle

https://www.911metallurgist.com/conveyors-maximum-angle-inclination-various-materials

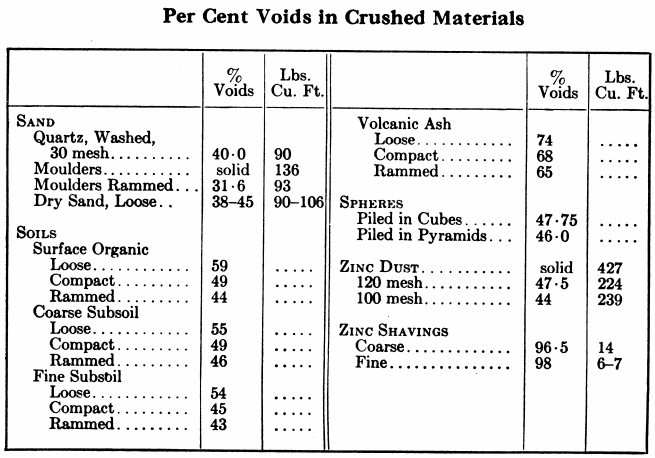

How much Void in Crushed Materials (Rocks, Sand, Soils)

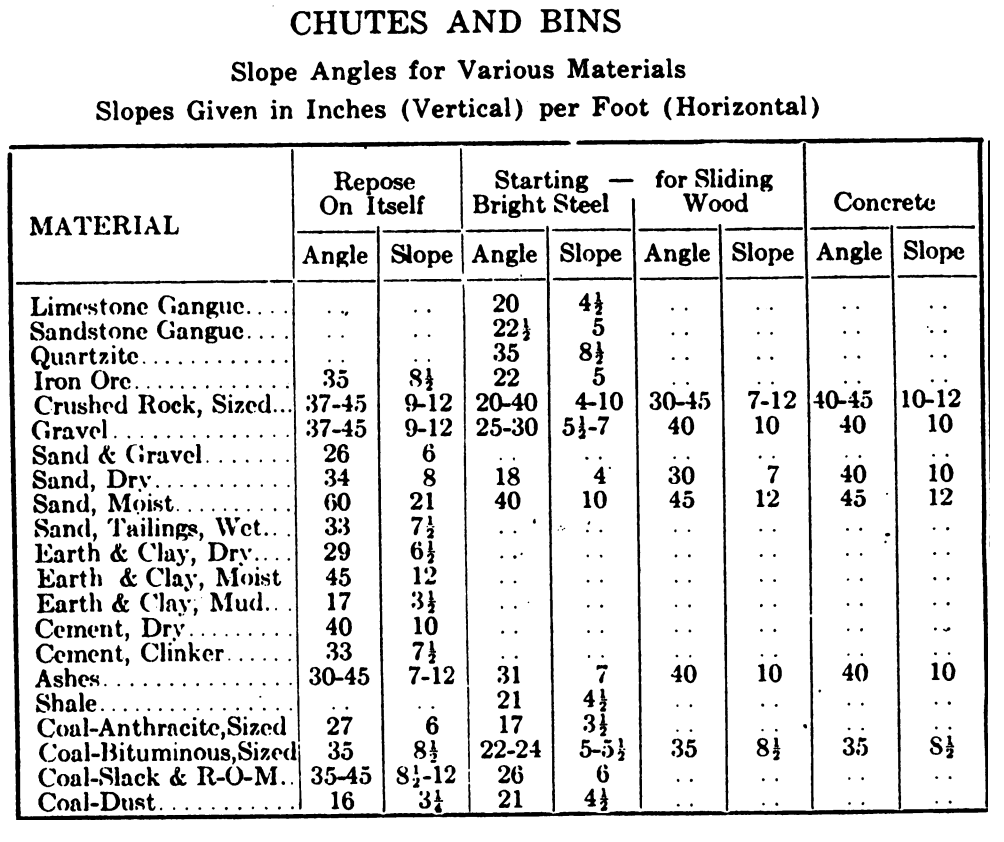

Slope Angles for Various Bulk Materials in Chutes and Bins

After starting sliding angle is 2°- 3° less. In practice, sliding angles are 5°- 10° more than above. Capacity of chutes is determined largely by the opening to the chute. In gates and other openings or restricted spaces in which pieces of rock are intermittently passing, the width should be at least 3 to 4 […]

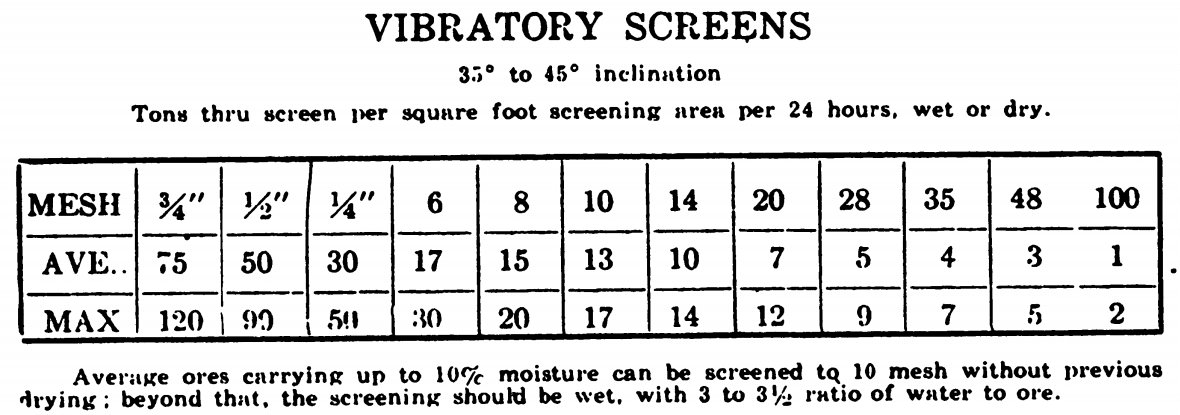

What is the Screening Capacity of Vibrating Screen per Area

Average ores carrying up to 10% moisture can be screened to 10 mesh without previous drying: beyond that, the vibratory screening should be wet with 3 to 3.5 ratio of water to ore. Approximate Tons thru screen per square foot screening area per 24 hours, wet or dry. moisture and screen efficiency Screen Capacity of Crushing Plants Screens […]