Rock Abrasion & Crushers

This section of the Paper deals with the abrasive character of rocks affecting crushing machinery. The investigation has followed two courses, firstly, an analysis of the existing data relating to the testing of road-making stones from its bearing on the abrasive wear of crusher-parts, and secondly, an experimental investigation into the correlation of abrasive wear […]

Jaw Crusher

This crusher is the finest of our lines of jaw crushers which we offer. Others include: Superior, Type “B” Blake, Fine-Reduction and Dodge — sizes, 4 by 6 to 84 by 66 inches. A reciprocating machine, the crushes material in a straight line between jaws — without grinding or rubbing surfaces. LOWER JAW CRUSHING COSTS As […]

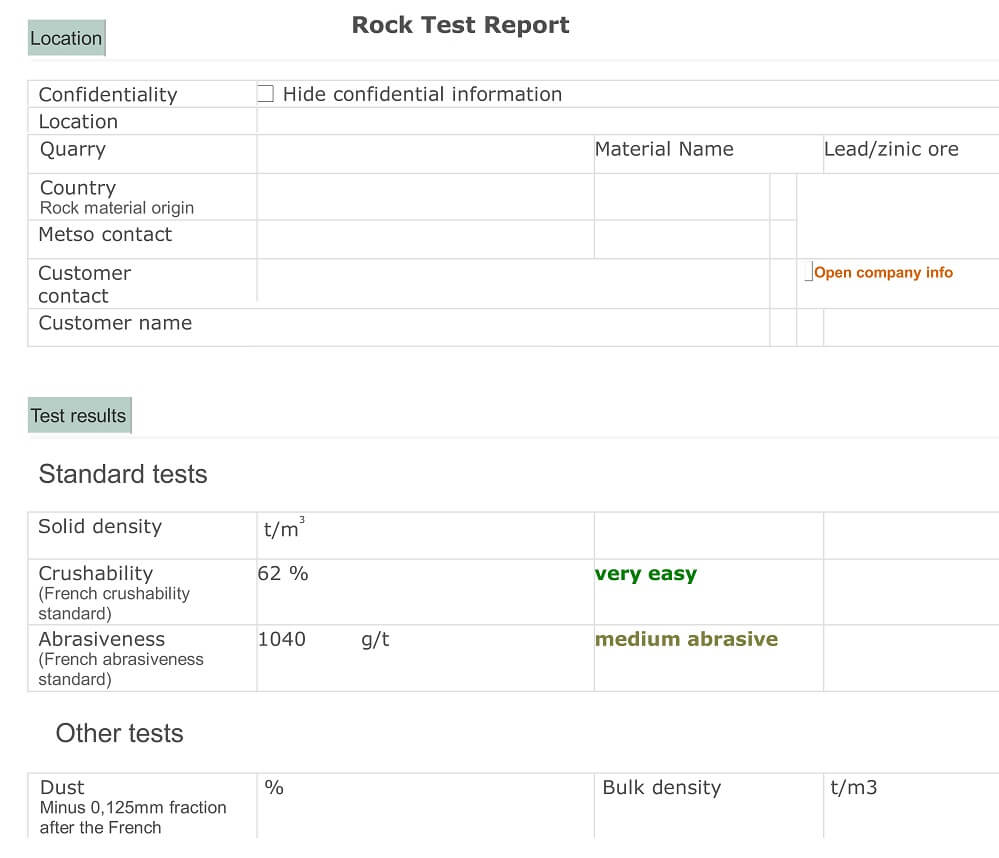

French Crushability & French Abrasion Index

The french crushability and french abrasion test gives an abrasivity index and a crushability index that will rate the material in comparison with other materials. The french abrasion test is mainly used to estimate hammer wear life in impactor applications. The crushability index is a measure of how easily the material breaks down. The test […]

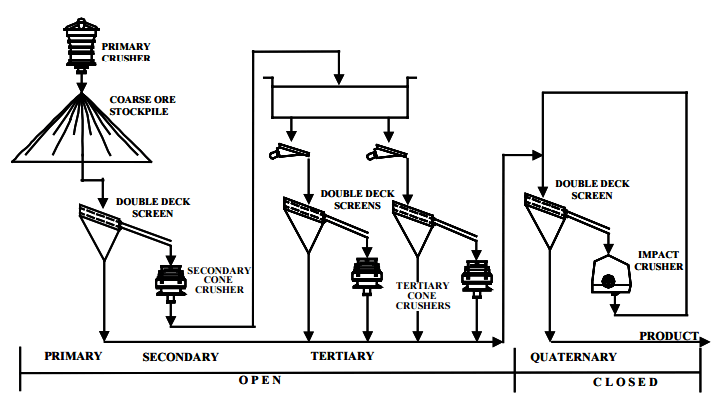

How to Size of Crushing Plant

When calculating the size of a crushing plant, it is not advisable to design a crushing plant to run for 24 hours per day. The machines are subjected to greater shocks and rougher wear than grinding and concentrating machinery and need more frequent attention in consequence. It is an almost universal custom to crush the […]

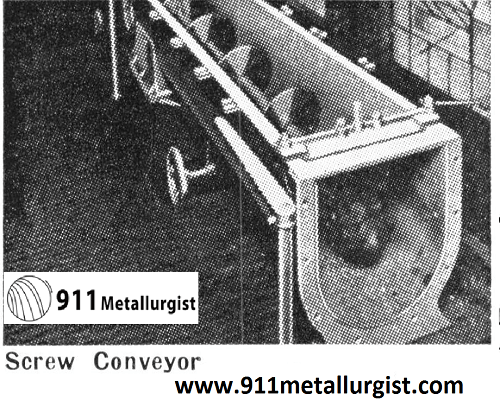

Small Screw Conveyor

Small Screw conveyors are used principally for bulk conveying of light and fluffy dry material, materials which dust badly when conveyed, hot materials which cannot be handled on rubber belts, and for conveying of liquid pulps. They may be installed on an angle for lowering or elevating materials. With the bottom or end of trough […]

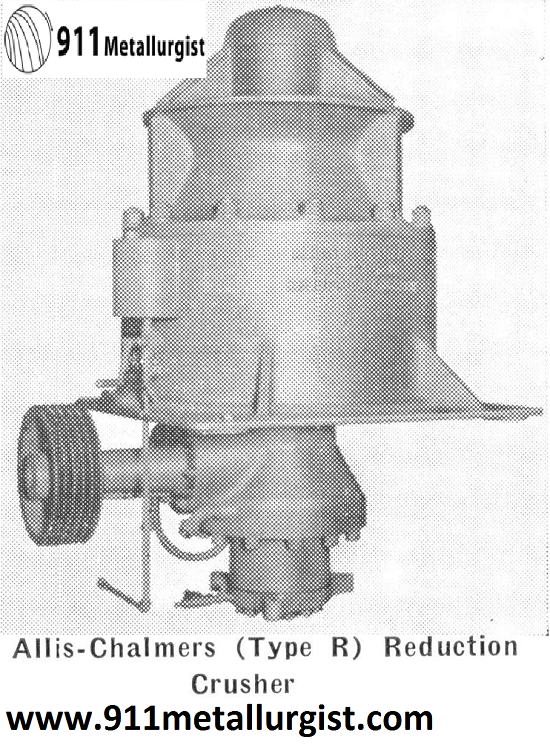

Small Gyratory Crushers

The Allis-Chalmers (Type R) Small Gyratory Reduction Crusher is designed for large capacity, fine crushing and incorporates many improvements over other gyratory type crushers previously manufactured by this company. The most distinctive feature of the Type R Crusher is the built-in, oil filled hydraulic jack used for fast, positive change of crusher setting while crusher […]

Unconfined Compressive Strength Test of Rock

This test method specifies the apparatus, instrumentation, and procedures for determining unconfined compressive strength of intact rock core specimens. This procedure is identical to ASTM D 2938 except that the cores are tested after cutting without grinding, and neoprene caps are used on the specimen ends. Unconfined Compressive Strength Test Procedure Check the ability of the spherical seat […]

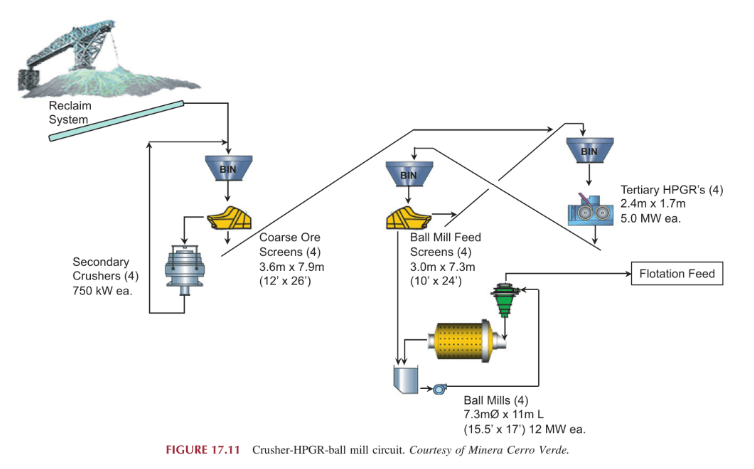

HPGR

HPGR or high-pressure grinding rolls have made broad advances into nonferrous metal mining. The technology is now widely viewed as a primary milling alternative, and there arc a number of large installations commissioned in recent years. After these developments, an HPGR based circuit configuration would often be the base case for certain ore types, such as […]

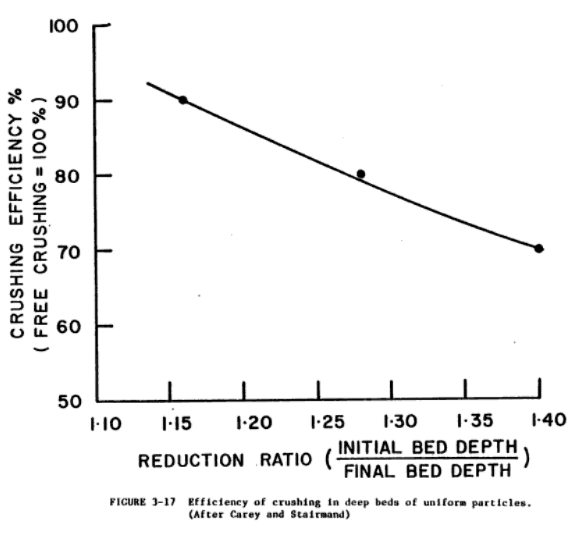

Crushing Efficiency Factors

Toward the foregoing goal, engineers investigated the energy efficiency of crushing for less than ideal cases. In the first experiment they studied the effect of factors such as using a deep bed of particles, a situation usually present in a ball mill. The same type of slow crushing experiment described above was performed, but with a […]

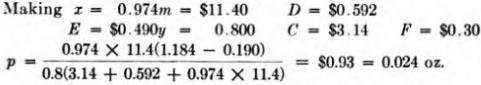

Ore Sorting & Pre-Concentration

Ore Sorting helps the economics of mining when ore becomes diluted by country rock because of narrow slopes or because of weak wall rock, or when it naturally contains barren material which is distinguishable from the ore, sorting and rejecting the worthless rock may be economical. This is done in a casual manner at some […]