Rock Crushers

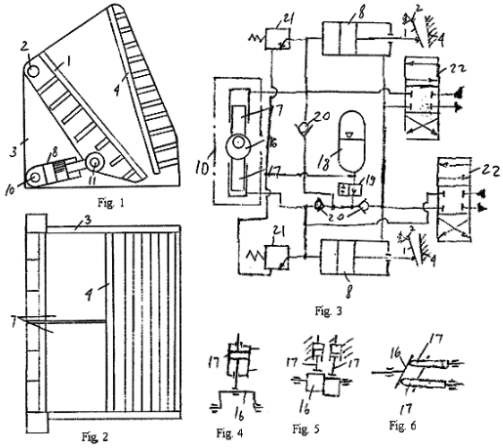

This invention relates to jaw rock crushers. In such known crushers, eccentrics or unbalanced rotors drive one or two oppositely situated swing jaws. The disadvantage of the known jaw rock crushers in comparison with known gyratory crushers lies in their cyclical work. i.e. the jaw makes one power stroke and one idle stroke during one […]

Optimized Laboratory Crushing Tests

The first step in minerals beneficiation of an ore is normally crushing which has been defined “as the operations required to reduce run-of-mine ore to grinding feed size”. It would therefore follow that the first metallurgical testing should be conducted on run-of-mine ore but, due to its size, this would be rather impractical. However, there […]

Chain Mill

A Chain Mill is a total amateur’s tool for “crushing or grinding” rock. It is a set of chains attached directly at the end of a 1700+ RPM motor. The chain will beat your rock to bug-dust, pulverise it, and any gold it might contain, into a size fraction so fine you will not be […]

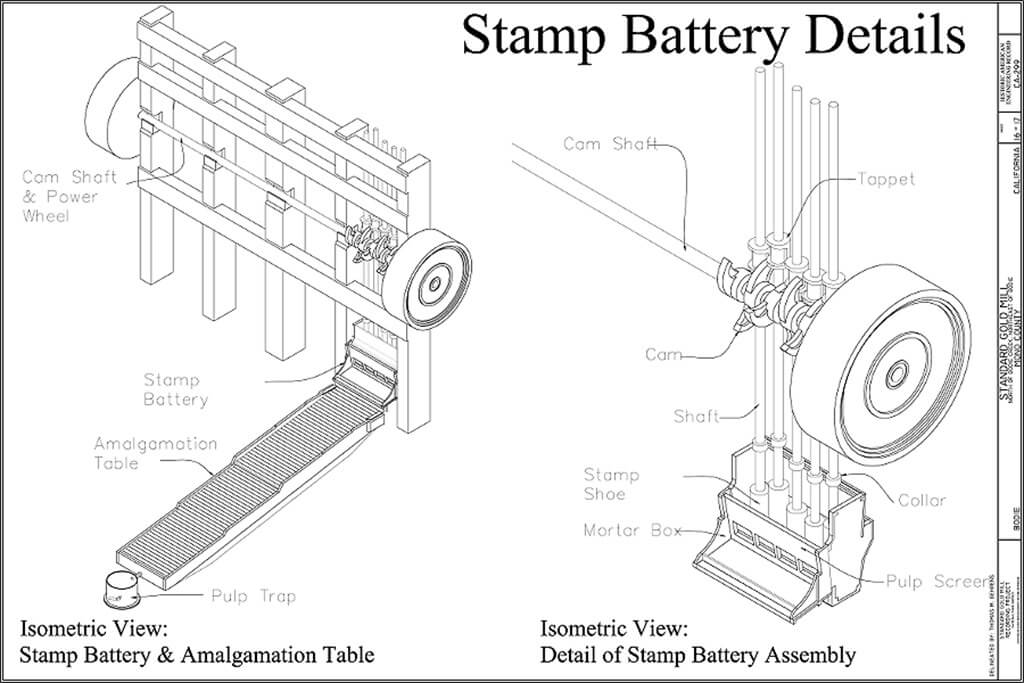

Roll Crushing VS Stamp Milling Compared

Comparison between Rolls and Stamps: As the subsequent treatment of an ore determines its method of crushing, no accurate general comparison of stamps and rolls can be made. A comparison is only possible in the special cases where both methods of crushing are applicable. Wet crushing by rolls need not be considered, as it is not […]

Steam Powered Stamp Mills

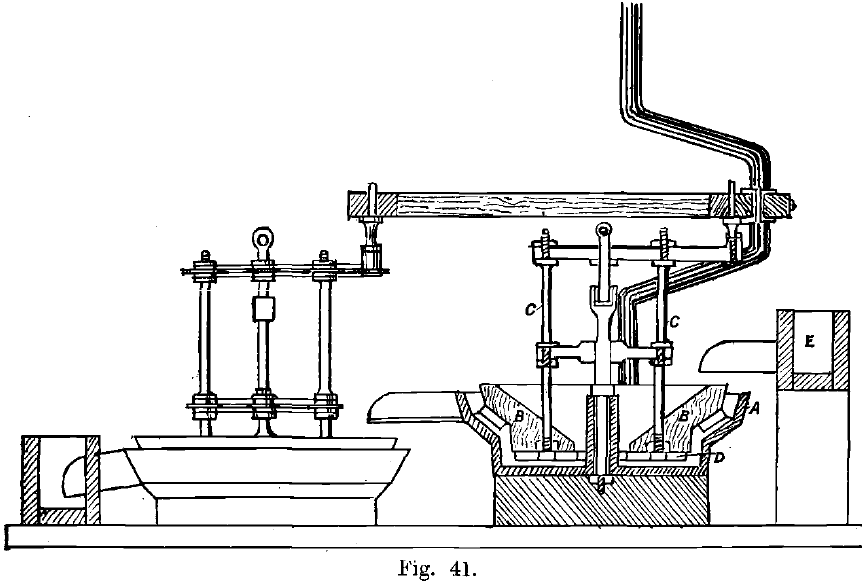

Since within certain limits and under certain conditions the capacity of a stamp battery depends on the number of blows given per minute and on the momentum of the fall, various contrivances have been suggested with a view to increase both of these. In pneumatic stamps, such as the Husband and Phoenix stamps, a crank […]

Roller Mills

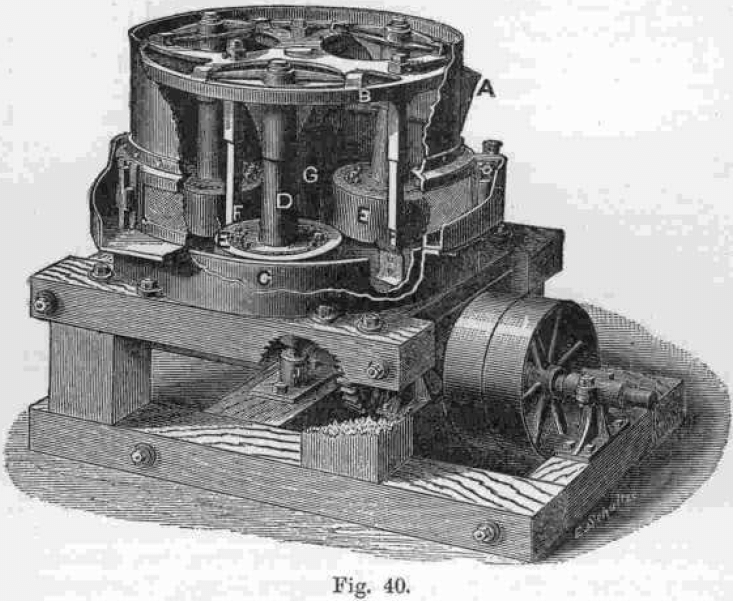

In the Griffin Mill, there is a single roller suspended in a similar way to the rollers in a Huntington mill. The roller is about 18 inches in diameter, and rolls on the inside of a die ring 30 inches in diameter. It takes material up to 1½ inches in diameter, and crushes either wet […]

Using Mercury in Gold Ore Crushing

The earliest machines used for the purpose seem to have been stone mortars, in which the gold quartz was crushed by stone-hammers, or by large rocks raised by levers and let fall, whilst the fine material was subsequently washed out with water. The heavy particles of gold then settled to the bottom of the mortar, […]

Stamp Milling

The stamp mill‘s battery evolved, no doubt, from the pestle and mortar was not introduced until a comparatively recent date. Beckmann states that mortars, mills, and sieves were used exclusively in Germany throughout the whole of the 15th century, and in France stamps were unknown as late as the year 1579. Brough has suggested that […]

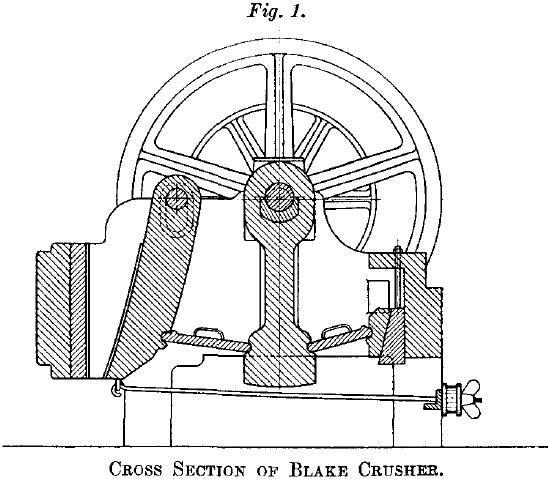

Rock Breakers

There are two classes of rock breakers machines in general use: Jaw crushers with reciprocating motion, and gyratory crushers The Blake and the Dodge crushers are representative of the former class, and the Gates and Comet crushers of the latter. The Blake Crusher is shown in section in Fig. 22. The rock is crushed between the stationary jaw, […]

Crushers

It is difficult to define exactly the meaning of the terms crushing and grinding, or crushing and pulverization; the finer crushing stages may embody a certain amount of pulverizing or grinding, but in the main, crushing may be said to cover the reduction of stones or ores to a size of ½ inch, and in some […]