Zinc Regrind

The flotation section starts with a bulk concentrate float for lead and copper using four rows of eleven cells each as roughers and scavengers. The froth taken off the roughers is then pumped to a two stage cleaner circuit. Scavenger froth and cleaner tails are returned back to the head of the rougher circuit. Froth […]

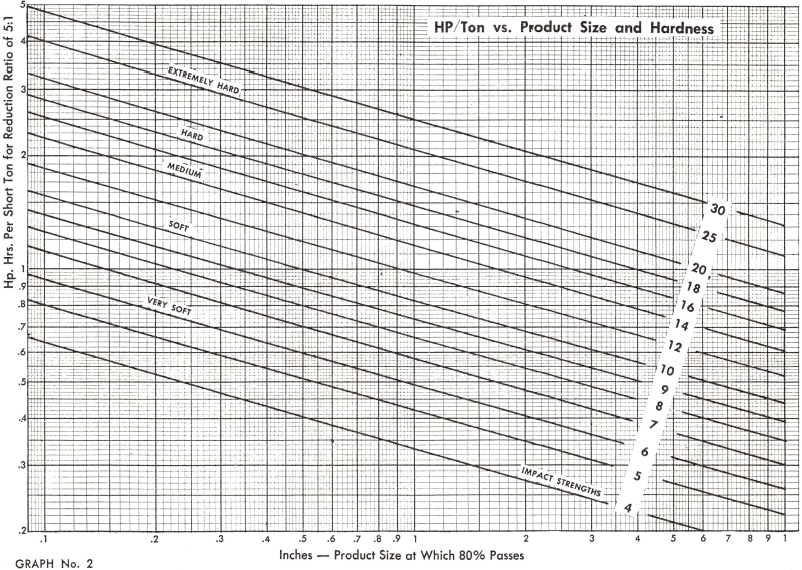

How to Size a Cone Crusher Motor

In the cone crusher capacity table, a maximum motor size recommendation is given for any eccentric throw. Only in rare circumstances is this maximum horsepower required; in many installations a motor of only half the rating of the maximum is required. If there is any doubt regarding the proper motor size, a sample of the […]

Cone Crusher Maintenance

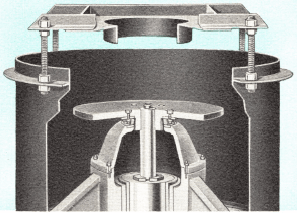

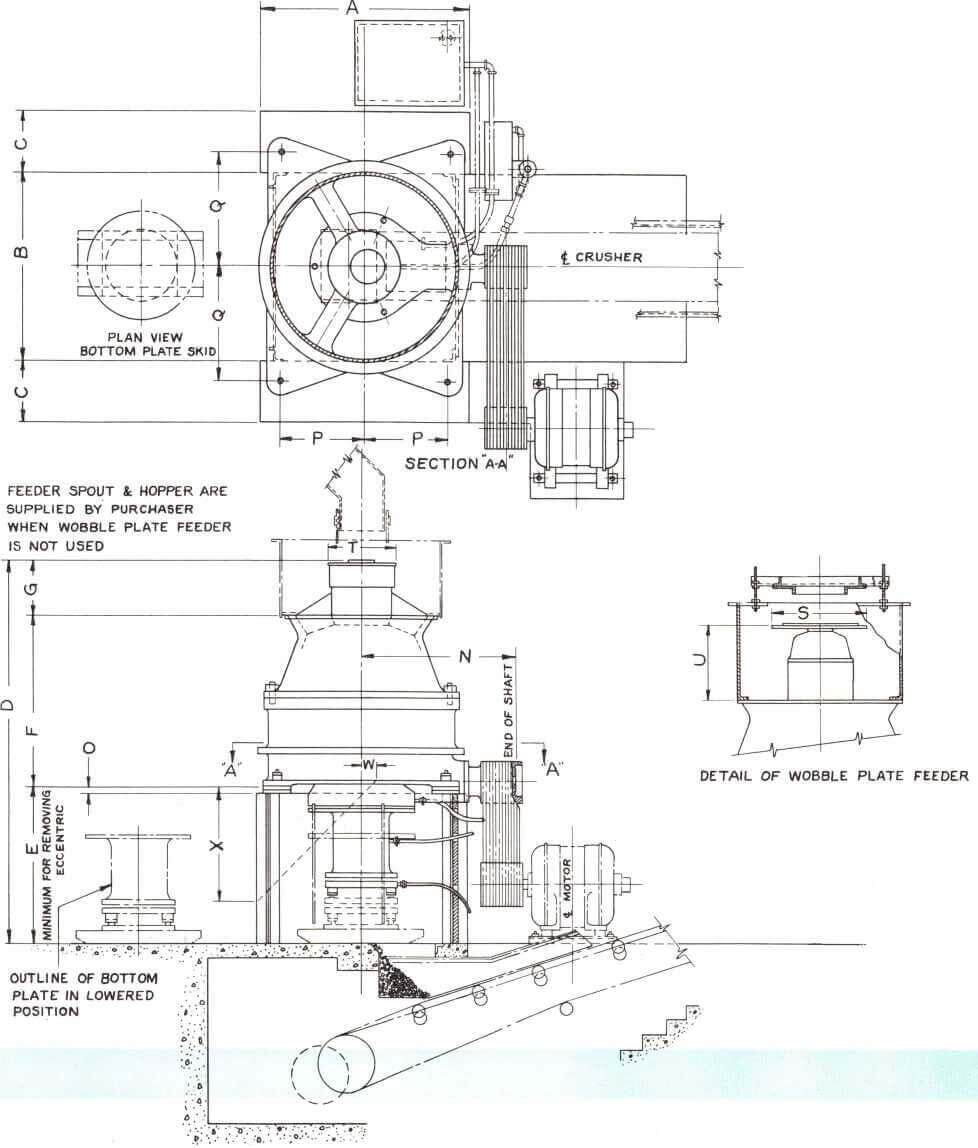

WOBBLE PLATE FEEDER A wobble plate feeder is furnished as standard equipment with Fine crushing chambers and as optional equipment with Coarse and Intermediate crushing chambers. It consists of a distributing plate to which a wobbling motion is imparted by the gyrating motion of the main shaft. The feeder is equipped with an enclosing hopper […]

Cone Crusher Installation

Tabulated installation drawings show the principal dimensions of the Hydrocone cone crusher, and are sufficiently accurate for preliminary plant layout work. In the smaller sizes (up to 48-in.) the Hydrocone crusher can be discharged vertically downward, or a feed spout can be provided which will convey the crushed product off to one side. Rubber shear mountings […]

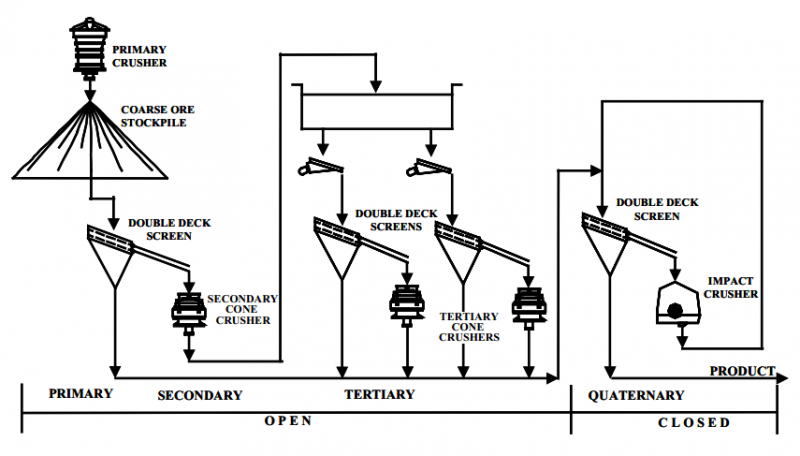

Cone Crusher Plant Design

The trend in the design of fine crushing plants is in the direction of the horizontal arrangement with all crushers on a single floor. Conveyors from the coarse ore bin or stockpile, feed the scalping screens which are usually double decked. When the feed to the fine crushing plant contains less than 15 percent passing […]

Portable Jaw Crusher

Comprehensive underground hard rock mining studies pointed out that significant reductions in ore handling costs could be attained if portable, low headroom, hard rock crushers were available to permit economical belt haulage from temporary locations close to production sites. Prompted by these reports a specific “Application Study of Portable Jaw Crusher” was initiated to quantify […]

Accuracy Determination for Conveyor Belt Scales

Increasing capacity of bulk material handling systems creates difficult problems for accurate in-line material weight measurements. At the same time increasing system complexity and growing user demands call for more measurements. Precision in-line weight measurements for bulk materials are usually accomplished by application of conveyor belt scales. Belt scale accuracies listed by scale vendors are […]

Secondary Crushing Simulation

The crushing plant simulator was utilized to evaluate the influence of major variables on the following responses: plant reduction ratio , weight % of -½ inch material in screen undersize, circulating load ratio and secondary screen efficiency. Variables manipulated were: weight % of +1 inch material in secondary crusher feed (73.3 to 92.9%), secondary crusher […]

Copper Ore Crushing, Grinding & Flotation

Crushing and Grinding You will note that the Oracle Ridge project has utilized a two-stage crushing circuit with a double acting jaw crusher and cone crusher. In order to utilize this system, the jaw crusher is oversized to produce all -5 material for the cone mill with a screen in closed circuit. Normally a three-stage […]

Rock Crushing

An objective of the present contract is to “provide a concept for the design of a portable underground hard rock crusher in order to insure that future development will lead to maximum utilization by industry”. The preceding section has concluded that the industry can indeed use such a machine and that, within desired performance and […]