Did you know it’s already possible to monitor and measure mining sites from space? That’s right. Thanks to the advances in imaging satellites and data processing technology, the industry has evolved into a point where it can successfully monitor mines from thousands of miles away.

Did you know it’s already possible to monitor and measure mining sites from space? That’s right. Thanks to the advances in imaging satellites and data processing technology, the industry has evolved into a point where it can successfully monitor mines from thousands of miles away.

Recently, the president and founder of the Canadian company PhotoSat wrote an article about this issue, which was published in Machine Control Online. According to the geophysicist Gerry Mitchell:

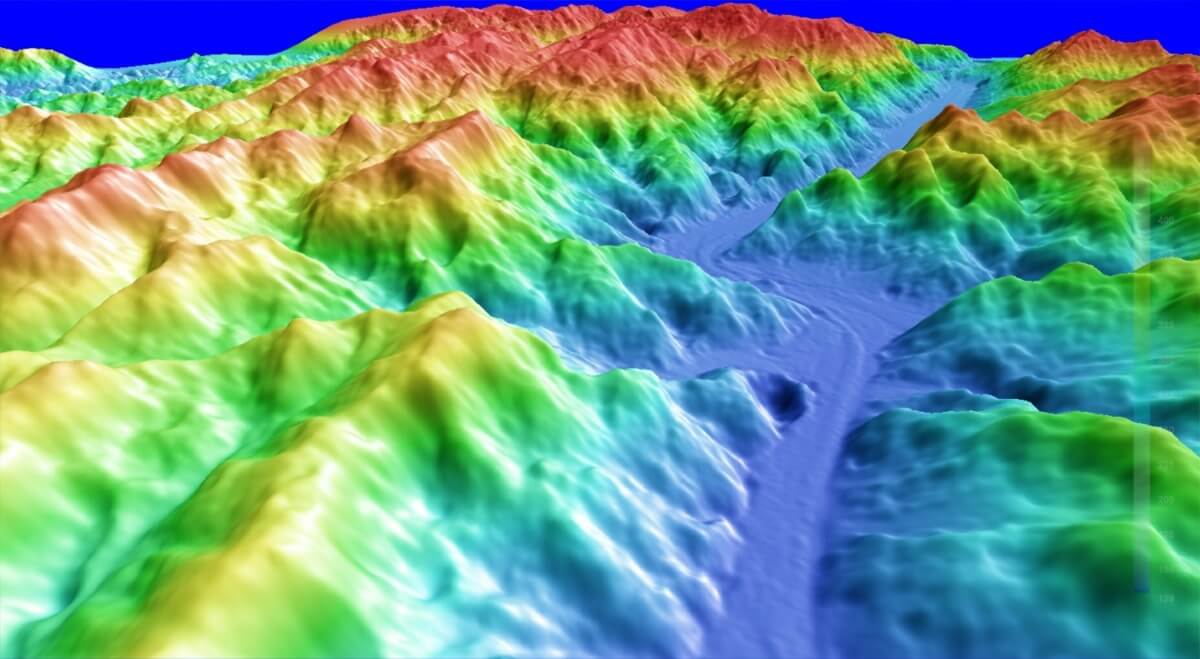

Mining pit, ore stockpile, leach pad, waste dump and tailings beach surface differences are being mapped to within 20cm. A number of mine sites are using this technology for annual and semiannual volume reconciliations. In the oil sands mines of northern Alberta this technology is being applied monthly and weekly.

There are now five commercial satellites in orbit with the capacity to map mine site surface elevation differences of 20cm. These are the WorldView-1, WorldView-2 and GeoEye-1 satellites owned by the US company Digital Globe and the Pleiades 1A and 1B owned by the French government. The Pleiades commercial satellite data is distributed by the European company ASTRIUM.

These applications started to be developed over the past decade. Today, these new operational mining engineering applications keep multiplying thanks to the change of the paradigm in satellite mine site monitoring and volumetric measurements.

PhotoSat, which is based in the international mining center of Vancouver, has invented new data processing algorithms that produce mine surface elevation maps accurate to 30 cm and elevation difference maps accurate to 20 cm. About this matter, Gerry Mitchell adds that:

When technology developed for processing topographic mapping from airborne photography is applied to the satellite photos the resulting mapping is generally only accurate to between 2 m to 3 m in elevation. This accuracy was not sufficient for PhotoSat’s mining engineering customers for design and operational applications so the company investigated other technologies that could provide better accuracy from the satellite photos.

When technology developed for processing topographic mapping from airborne photography is applied to the satellite photos the resulting mapping is generally only accurate to between 2 m to 3 m in elevation. This accuracy was not sufficient for PhotoSat’s mining engineering customers for design and operational applications so the company investigated other technologies that could provide better accuracy from the satellite photos.

PhotoSat found that by applying technology developed in the oil industry for the processing of oil exploration seismic exploration data to the mapping of topographic surfaces from satellite photos they could achieve mapping accuracies of between 20cm and 30cm in elevation. Digital processing of oil exploration seismic data began in the 1960’s and has been the subject of billions of dollars of research and development investment ever since.

The seismic processing field includes many sophisticated tools for image matching, signal enhancement and noise attenuation that, to PhotoSat’s knowledge, have never before been applied to topographic mapping from satellite photos. This is a classic case of the transfer of technology between different technical fields resulting in a significant technical breakthrough.

The topographic mapping of mine sites is generated from pairs of satellite photos taken approximately one minute apart. The satellite focus its telescope on the mine site by approaching the location from the north, at an altitude of over 700 kilometers. Then, it’s time to start taking pictures, travelling at seven kilometers per second. Next, the satellite keeps moving and focusing its telescope to take more pictures.

The pointing of the satellite telescope is controlled by the forces created by variations in the electric current flowing in coils of wire in the satellite, moving at 7 km per second through the earth’s magnetic field. The position, orientation and speed of the satellite is so precisely controlled and measured that the resulting topographic maps are usually accurate to 2 m without any ground survey control. By matching the resulting satellite mapping to a single ground survey point the satellite mapping is accurate to 30 cm in elevation for up to 10 km in all directions from that ground survey point.

As stated by the Canadian geophysicist, satellite mapping has a significant advantage over airborne surveying for mine sites in remote locations. Well, for the satellites, all areas of the world are “close” and let’s not forget about the fact that satellite mapping requires absolutely no in country permits or presence, so it’s not subject to bureaucratic delays. With the global access provided by the satellites, companies with mining operations in various parts of the world can use a consistent mapping process for all of their mine sites.