Table of Contents

You have all seen a gas stove. Gas burns with tiny, bright-blue cones of flame; they are very hot, very clean, very quick to burn. You have also seen a hardwood fire; when the yellow flame disappears, the charcoal gives off a bright

blue, almost transparent flame. Again, this flame is hot, very clean, very quick to roast hot dogs.

How Does Our Burner Work?

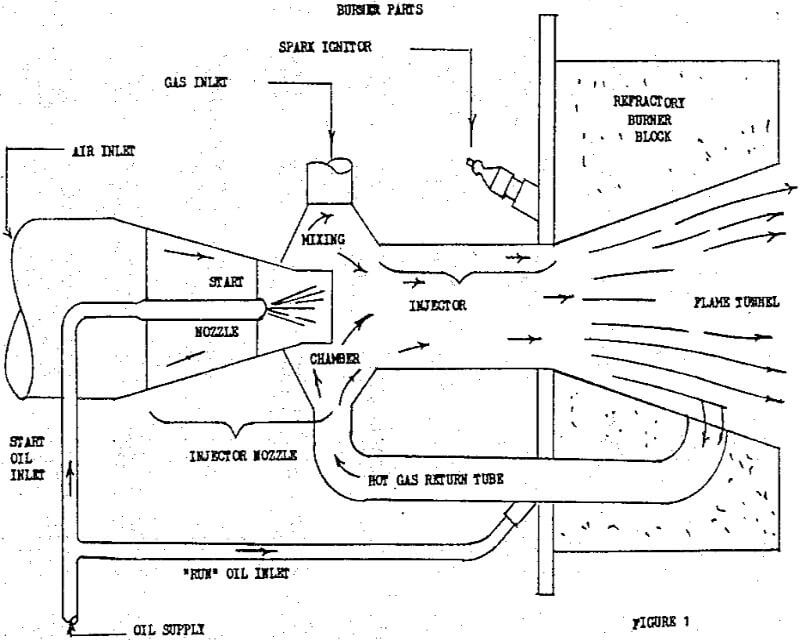

High pressure air from a blower enters through the injector nozzle. Pressure is converted to velocity as this air leaves the nozzle. As the high velocity air passes into the injector, it entrains more air from the mixing chamber. Both the blower air and the entrained air are again compressed as they are driven through the injector creating a venturi effect with a resulting vacuum in the mixing chamber. The mixing chamber is connected to the flame tunnel by an open tube which we call the “Hot Gas Return Tube”.

This atomized oil is not a gas, but a vapor. Therefore, the flame burns in the flame tunnel with a distinctly yellow color – just like most oil burners. You probably wonder why we must use this conventional way to start our Blue Flame burner. If you recall, I said it takes heat to convert oil to gas. As a matter of fact, fuel oil must be heated to 600° before it converts totally to gas. This heat must come from somewhere. In our burner, the heat is drawn from the yellow starting flame.

Gas Firing the Blue Flame Burner

Gas is easy to fire in the Blue Flame burner. It is much easier than oil because the fuel is already in the gaseous state. It burns immediately when mixed with air and touched by a spark. For this reason, it is considerably more dangerous. No extra heat is needed to gasify the fuel, therefore no “Start” cycle is necessary. We simply turn on the gas, start the air through the injector and spark the ignitor. Combustion is instantaneous so long as air and gas are in correct proportion.

One of the most important things to remember when burning gas in our burner is that the hot gas return tube is heating up just the same as it would be on oil. When running on oil, the liquid oil entering the return tube keeps the return tube from over heating. When firing on gas, this oil is not entering the return tube. Therefore, some other means is needed to keep the tube cool. Cooling is simply done by opening a valve and allowing part of the combustion air that normally goes through the air nozzle to be diverted into the hot gas return tube here.

Why Does the Blue Flame Reduce Air Pollution?

The chemical process known as combustion is the combining of the carbon and hydrogen atoms in the fuel with the oxygen atoms found in air. The basic reactions are:

C + O2 → CO2

2H2 + O2 → 2H2O

When combustion is complete, a great amount of heat is released, and two non-polluting gases are discharged into the atmosphere; CO2 (carbon dioxide) is a harmless gas absorbed by plant life and H2O is simply water in the form of steam.

Unfortunately many fuels contain other undesirable elements such as sulfur, vanadium, chlorine, and certain oxides of metal. These, when burned, can form pollutants such as SO2 (sulfur dioxide), H2SO4 (sulfuric acid), HCl (hydrochloric acid) and other unwanted gases and vapors. These pollutants are not controllable by the burner. They will always exist, if found in the fuel.

However, in addition to these uncontrollable pollutants, most burners will not burn their fuels completely. Therefore, other pollutants result:

Excess C + O2 — CO + C (Carbon Monoxide + free carbon)

N2 + Excess O2 — NO, NO2, NO3, NOx. (Nitrogen Oxides)

Selection Of Burners

Now that you know how a Blue Flame burner works on the inside, and what it can do to burn fuel efficiently, we must look at how to put one together and make it perform. Analysis of the burner shows that it requires four things in order to operate as a dual fuel burner. It can also offer efficiencies as either a gas or oil single fuel system.

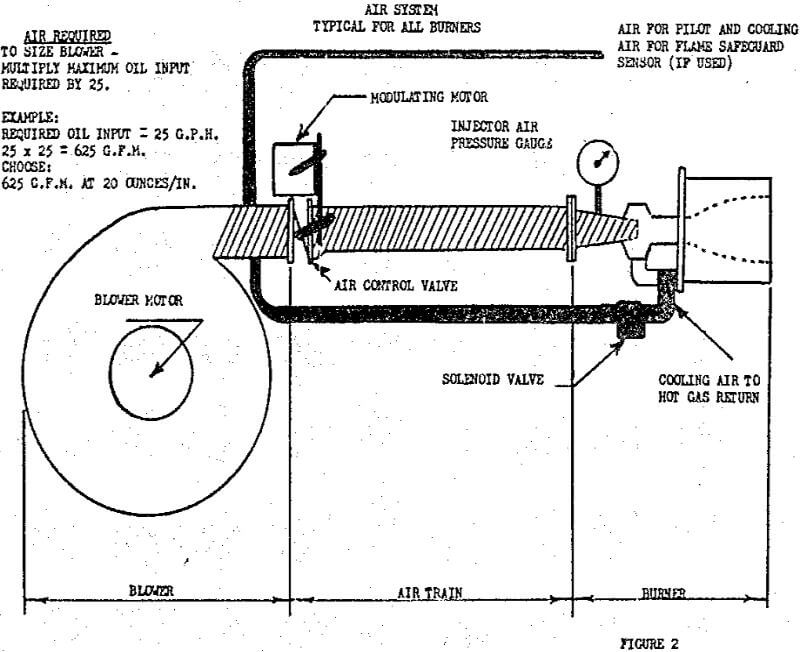

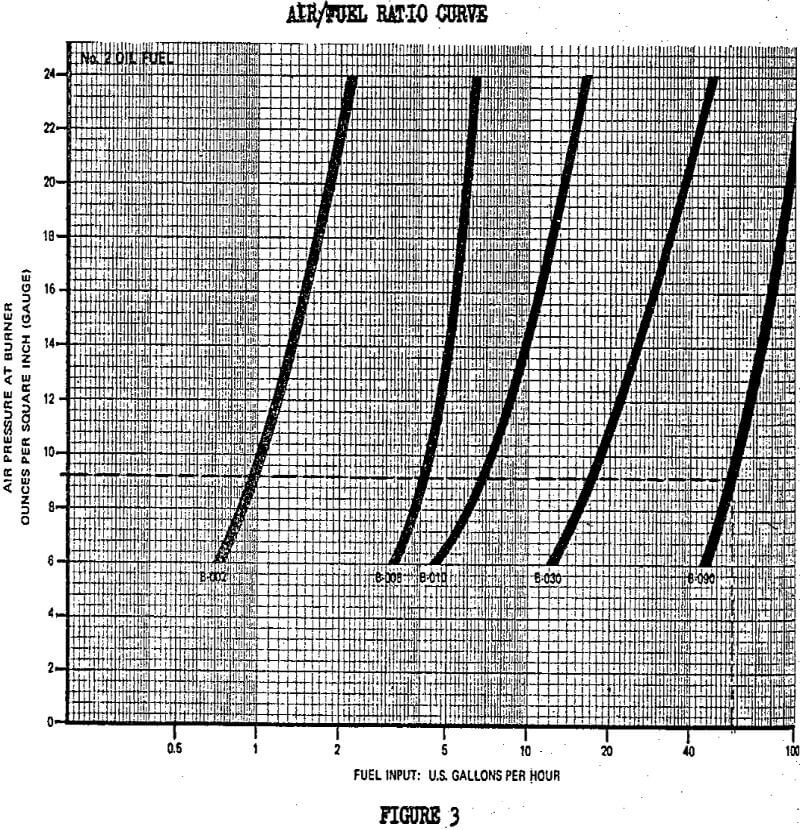

Air is provided to the burner by a motor driven blower. Each blower should be sized to supply enough air for the burner to operate throughout the range required by the process.

When the proper blower is selected, we are ready to put together the entire “air train”. The butterfly air control valve can be on the blower inlet or outlet. It can be either manually or automatically operated. In either case, its function is to regulate the exact amount of air needed to burn the fuel being pumped into the burner. In most cases, the burner will be equipped so that the operation of the air valve is directly in proportion to fuel input at all times. This is done in several ways.

To provide fuel oil to the burner, a pressure of 80 to 100 psi is required as standard. This pressure is provided by an oil pump. The pump can act as a transfer unit if the storage tank is near by. If not, a second pump, located at the storage tank may be needed to bring oil through a long pipeline to the burner pump. Oil pumps are usually sized to deliver 150% of the maximum required by the burner. This is done to assure against pressure fluctuations, pipe line restrictions, and cold oil which does not pump as readily. The pump should always have a built-in by pass valve to allow for pressure adjustment and relief. Again, like the blower, more than one burner can be operated from a single pump so long as that pump is sized to carry the total oil requirement. Pumps are usually connected to motors and require very little attention when sized correctly.

To burn gas, no changes to the oil system are necessary, we merely add on the required gas equipment. This consists of removing the plug from the gas inlet, adding a limiting orifice gas valve, an air/gas ratio regulator and an manual gas shut-off valve. To this system, gas must be supplied at a constant pressure of 1 PSI.