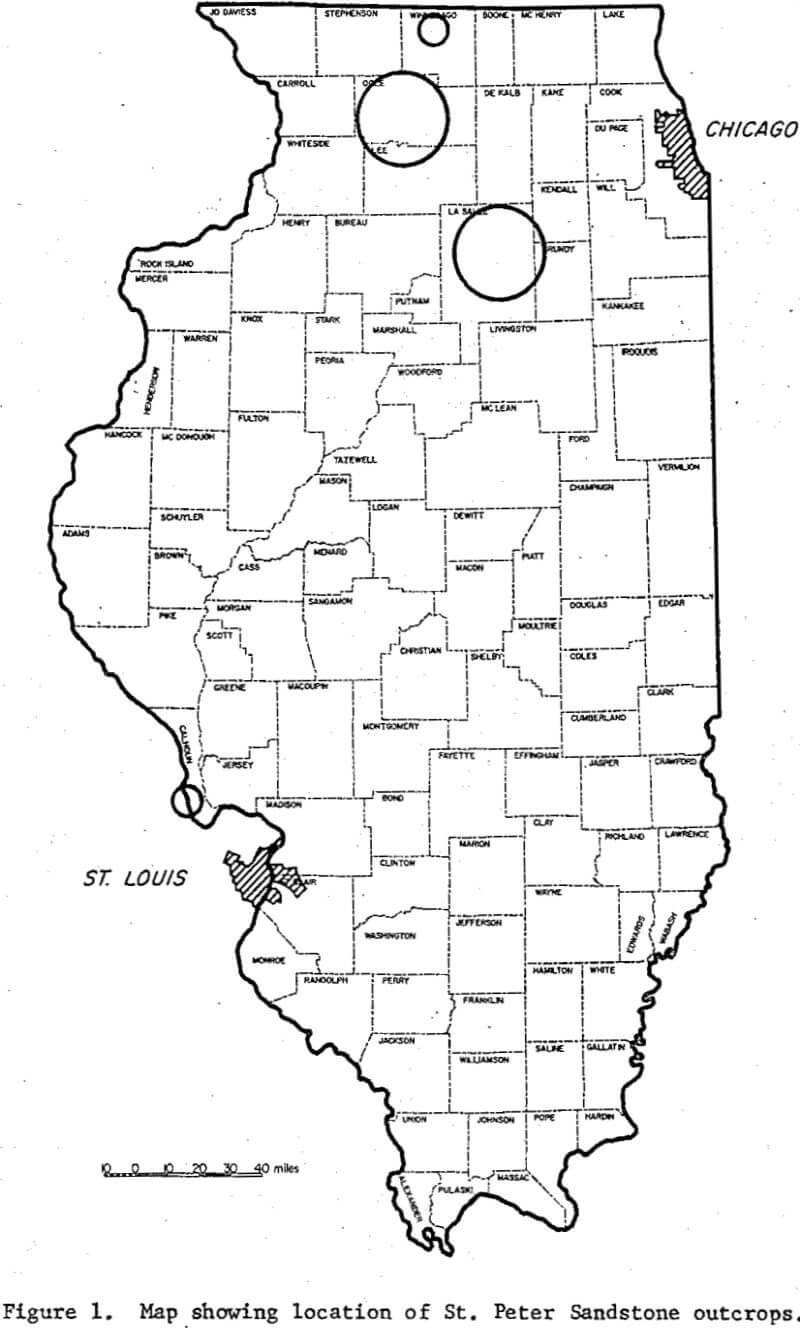

Silica sand has been mined in Illinois from the St. Peter Sandstone since the turn of the century, especially in the area around Ottawa on the Illinois River in the north-central part of the state. Production of this sand, consumed mainly by the glass and foundry industries but also sought after for many other uses, has grown with the economy.

The St. Peter Sandstone is early Middle Ordovician in age (over 450 million years old) and crops out at four areas in Illinois. However, silica sand is currently being mined and’washed from the St. Peter only in LaSalle and Ogle Counties. In these areas, the formation varies from 140 to over 200 feet thick. It is mined only to a maximum depth of about 90 feet, due to water problems and increasing iron content at depth.

All of the mining is done by open-pit methods. The overburden, which varies from 6 to 30 feet in thickness, is removed by bulldozer and scrapers. The sand body is then drilled from the top and the face blasted down with light charges of dynamite. The sand is mined in a single face in all but one case where it is taken in two benches because of its greater minable thickness and the significant difference in grain size that exists between the benches.

After washing and draining, the sand is dried and either sold without sizing or screened for specialty uses. Two Illinois plants also grind washed sand to make a silica flour product. Another plant coats a portion of its sand production with a thermo-setting resin for use in foundry sand cores.

Because the washing operation generates a clay-rich waste product, the beneficiation of which will be discussed in this paper, a closer look at this technique is in order. The simplest washing operation involves passing jets of water upwards through a fluidized bed of sand in a concrete tank. The overflow water carries fine-grained sand and clay up and out of the bed; this overflow is then pumped to the waste pond. More complex washing schemes utilize scrubbers, followed by either mechanical classification or hydrocyclones, or a combination of both. The different ratios of sand to clay among the wastes of the seven plants reflects the variable nature and degree of washing of the raw sand.

The methods of washing the clay out of the sand utilized in each of the plants vary considerably in their efficiency. In every case, however, the sand from the washer is almost completely free (less than 0.1 percent) of the clay material that occurs in the natural sandstone.

In the hydrocyclone process, the plant outflows were thickened in the laboratory to 35 percent solids before beneficiation. No settling aids were needed due to the rather highly flocculated condition of the pulp. This slurry was then put through a 30 mm. laboratory cyclone with a vortex to apex ratio of 4½:1 and a water pressure of 15 to 20 pounds per square inch; these values were determined to give optimum sand-clay separation.