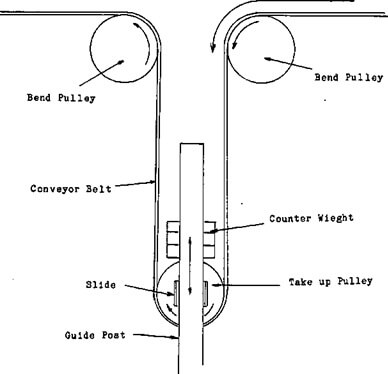

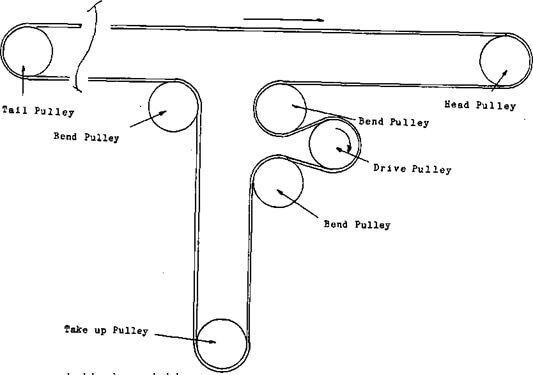

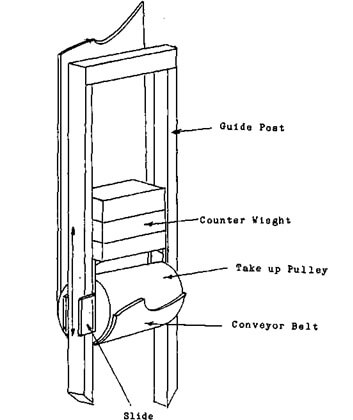

The length of this second type of conveyor requires that a BEND PULLEY and a TAKE UP PULLEY he added to the return portion of the conveyor belt. The longer belts will have a greater expansion and retraction rate due to climatic temperature changes. As temperature climbs the belt will get longer. When it drops the belt will shrink. To compensate the conveyor belt will have a pulley that is allowed to move with the belt as its length is constantly changing. To keep proper tension on the conveyor belt the pulley, which is called the take up pulley, is weighted. The bend pulleys are called that because the belt bends over them to form a loop for the take up pulley to sit in.

Now for our third conveyor, this conveyor is much like the second except for one major change.

Now for our third conveyor, this conveyor is much like the second except for one major change.

The drive unit has been taken from the head pulley, and placed after the first bend pulley on the conveyor return.

Adding another pulley designed especially as a drive unit requires another bend pulley to maintain tension on the drive pulley. The advantage of this positioning of the drive unit is that it creates a greater leverage and helps prevent slippage between the drive pulley and the belt.

You will find this type of conveyor drive on very long conveyors where more than one drive may be required, or situations where the load is great enough to need the added leverage.