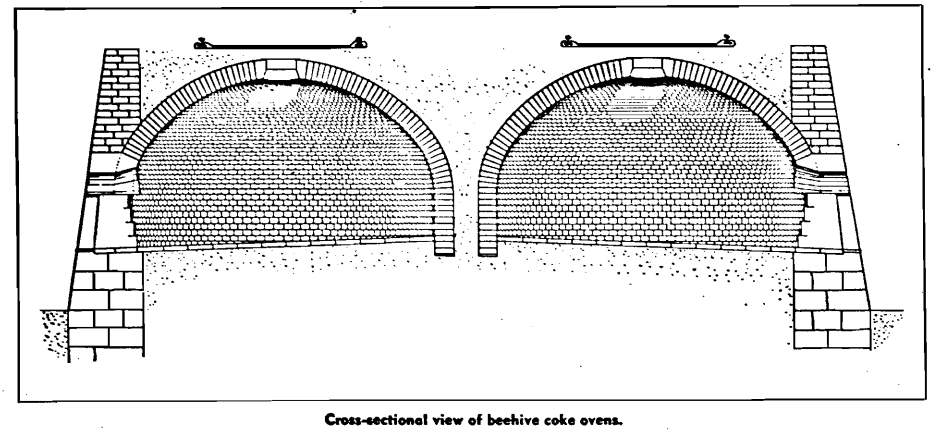

During the latter half of the nineteenth century and the early years of the twentieth, the major percentage of metallurgical coke produced in the United States came from beehive ovens. It was not until 1893 that the first battery of by-product ovens came into operation (at Syracuse, N. Y.), and only in 1919 did the total production of by-product coke first . exceed that from beehive ovens. Peak output of beehive coke occurred in 1916 when 35,464,224 tons were produced as opposed to the 19,069,361 tons carbonized in by-product ovens. The Connellsville district of Pennsylvania was not only the birthplace of the oven coking industry in the US, it was in this region also that the most extensive growth of beehive coking operations took place. There were two reasons for the rapid development of the coke industry at Connellsville. First, enormous quantities of excellent coking coal were readily available from the Pittsburgh seam of the Connellsville basin. Secondly, adequate rail and water transportation facilities allowed the coke to be shipped as far west as California, south to New Orleans, and to such eastern cities as New York and Baltimore. In the special report on the Coke Manufacture of the Youghiogheny River Valley issued in 1875 as part of the Second Geological Survey of Pennsylvania, the Pittsburgh Coalbed in the Connellsville Basin was described as occupying a trough 3 mi wide and 50 mi long, and giving from 8 to 9 ft of workable coal that was soft, easily and cheaply mined, and yielded a coke of unusual excellence. At the time of the Survey, the coal could be mined, coked, and loaded on cars at the ovens for $0.0275 per bushel, or $1.37 per net ton. A typical analysis of the Pittsburgh coal then mined at Connellsville was given as: moisture-1.3 pct; Volatile Matter-30.1 pct; Fuel Carbon-59.6 pet; Ash–8.2 pct; and Sulfur–0.8 pct. Owing to its columnar structure and friable nature, Conesville coal was ready broken during mining and handling, and thus arrived at the coke plant in comparatively small, uniform pieces. Since it was also free from any considerable impurities, it could be charged to the beehive ovens without any form of preparation.