Table of Contents

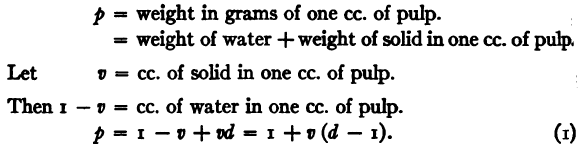

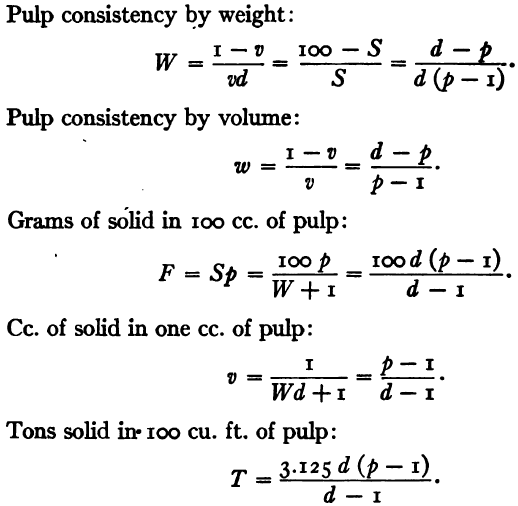

Definitions. “Pulp,” in flotation terminology, is a freely-flowing mixture of powdered ore and water. “Pulp density,” when the phrase is applied properly, indicates the specific gravity of the pulp. “Percentage of solids” means the ratio, expressed as a percentage, of the weight of the solids in a pulp to the total weight of pulp. “Pulp consistency” is the ratio, by weight or volume as the case may be, between the number of parts of water and the number of parts of solid in a unit of pulp. The number of parts of solid is usually taken as one in the numerical expression, thus six to one. In the following formulas, the various quantities listed are represented by the letters set after them below: Pulp density, (p); specific gravity of dry solid, (d); specific gravity of water, (I); percentage of solids, (s); pulp consistency by weight, (W), by volume, (w); grams of solid in 100 cc. of pulp, (F); tons of solid per 100 cu. ft. of pulp (T);

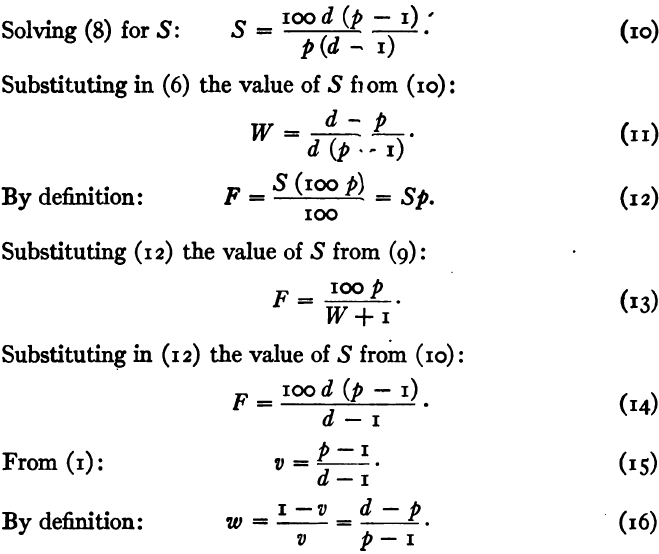

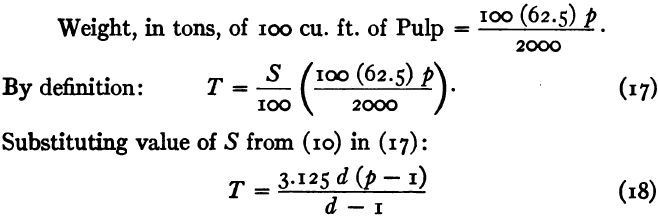

Development of formulas.

By definition:

Hence:

Substituting value of v from (3) in (1):

Collected Formulas

Pulp density:

Figure 18, page 80, presents graphically the relation between S, p and d and is useful for rapid pulp calculations in mill testing.

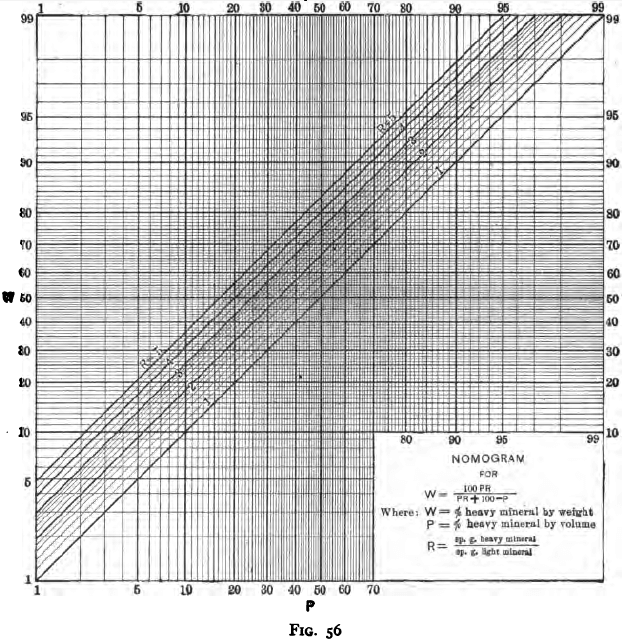

Figure 56 is useful, especially in connection with microscopic work, for lessening the labor necessary in translating percentage by volume into percentage by weight and vice versa.

Metallurgical Formulas

Definitions. The feed or material treated in a metallurgical operation or machine is usually called “heads” or “heading”; the valuable product is called “concentrate”; the impoverished reject is called “tailing”; and any intermediate, unfinished product, insufficiently enriched or insufficiently impoverished, is called “middling.” The ratio of the weight of the sought mineral or metal obtained in the concentrate to that present in the heads, expressed as a percentage, is called the “recovery.” The ratio of the weight of heads to the weight of concentrate is called the “ratio of concentration.” In the following formulas weights and assays of heads, concentrate, tailing and middling are represented by their capital and lower case initial letters respectively; recovery is indicated by R and ratio of concentration by K.

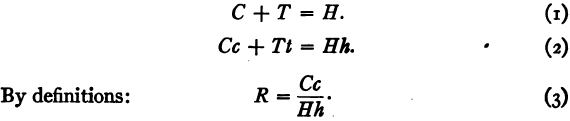

Recovery may be determined in any mill operation where concentrate and tailing are the only final products, if the assays only of heads, concentrate and tailing are known. This fact becomes apparent from the following relations:

Ratio of concentration may also be expressed in terms of the assays of heads, concentrate and tailing.

Thus, by definition:

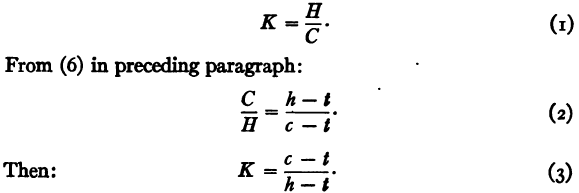

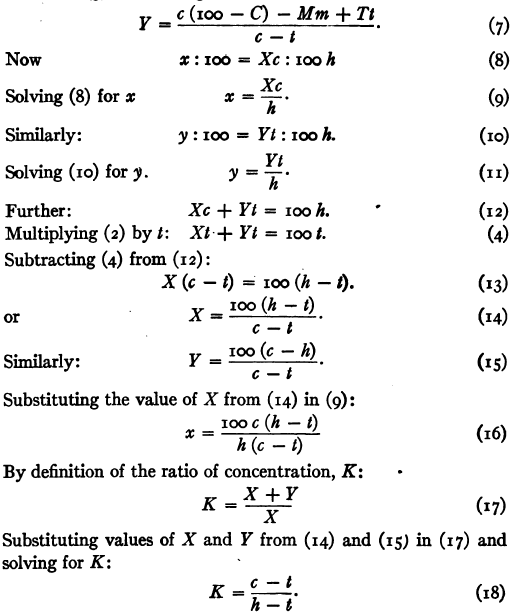

Adjustment of middling. In a laboratory testing operation a middling is usually produced. Clennell* develops formulas for the mathematical disposition of this product as follows:

Assume that, as in practice, the middling will be returned to the same machine or operation; and that the assay of the tailing and concentrate will not be affected by this procedure; and that the middling is not of different mineralogical composition from the original heads. Then, if C, M and T represent the percentage weights of concentrate, middling and tailing respectively; X and Y represent respectively the percentage weights of concentrate and tailing that would be obtained with the middling eliminated, i.e. retreated and thus distributed; and x and y the percentages respectively of the total values in the two final products; the following mathematical relations hold:

Similarly, multiplying (2) by c, subtracting the resulting equation from (3) and solving for Y:

It will be observed that the value of “x” obtained in (14) is the same as the value for R previously obtained and that the value for K just derived is the same as that which was derived for mill operations. In other words, as was to have been anticipated, if the assumptions made at the beginning of the paragraph hold true, equations (6) and (7) give no more information than does equation (18) which is the same as equation (3) of the preceding paragraph, and the “x” in equation (16) is the recovery, R, previously developed.

The assumption made by Clennell that middling obtained in a laboratory testing operation would, in a mill operation under similar conditions, if returned to the head of the machine, be distributed in such a way as not to alter the assays of concentrate and tailing, is not strictly correct in any case. Under certain conditions, however, in flotation testing, it is legitimate to disregard the middling in the calculation of recovery and ratio of concentration. Whether or not the product may be disregarded is to be determined in any given case by a microscopic examination and an assay. If microscopic examination shows that the valuable mineral in the middling is not too coarse to float, nor too large a proportion in the form of included mineral, i.e., not yet freed from gangue, and is not a different mineral, as for instance all chalcopyrite while the original feed contained both chalcocite and chalcopyrite, or an oxidized copper mineral when the feed contained both sulphide and oxide copper; then, if the assay of the middling is not more than twice that of the original feed, or if the bulk of middling is small in relation to the original feed, although the assay is more than twice that of the original feed, the middling may be disregarded in calculating recovery and ratio of concentration. Otherwise the middling should be retreated to determine its behavior. Under any of the contingencies noted it will probably be found that the recovery on middling is poor. If the mineral is coarse, classification in a mechanical classifier followed by tabling of the sands is the solution. If the valuable mineral exists as included grains, regrinding is the only solution and will probably not pay. If the middling is returned it will build up until it must be discharged from circuit either as concentrate or tailing, in which case it will lower the grade of the concentrate or raise the metal content of the tailing. If the middling is of different sulphide content from the heads, i.e., predominantly chalcopyrite, for instance, as compared to a mixture of chalcocite and chalcopyrite in heads, retreatment in a different machine with different flotation agents is the procedure indicated. If the middling is oxidized mineral containing the same metal as the sulphide in the heads, the problem becomes one of the treatment of an oxidized ore, in a different machine, of course.

Capacity, metric. The liter (1.) is the unit and is the equivalent of the volume occupied by the mass of 1 kilogram of pure water at maximum density. The smaller units usually employed are the cubic centimeter (cc.) and the cubic millimeter (cu. mm. or mm.³) which are, for all practical purposes 0.001 and 0.000001 liters respectively.

* “The wood Flotation Process,” H. E. Wood, Trans. A. I. M. E., 1912.

* O. B Hofstrand, Bul. A. I. M. E., May, 1912.

* Eng. and Min. Jour., Oct. 30, 1915 and Jan. 1, 1916.

Pulp Formulas & Metallurgical Formulas P. 228-244